RaisedByWolves

Addicted to ArboristSite

No wonder EKKA calls himself the PalmSlayer!

:jawdrop: Them things fight back! :jawdrop:

:jawdrop: Them things fight back! :jawdrop:

.png) is wondering if you have before and after pictures of the dishwasher. :biggrinbounce2:

is wondering if you have before and after pictures of the dishwasher. :biggrinbounce2:

Buckeye said:I've used the dishwasher to clean up old gun stocks, but I never thought of using it for chainsaws/greasy parts. Good idea.

(the Witch told me, but actually, I already new), but saw parts is perfectly OK, unless it is an unplugged motor.......

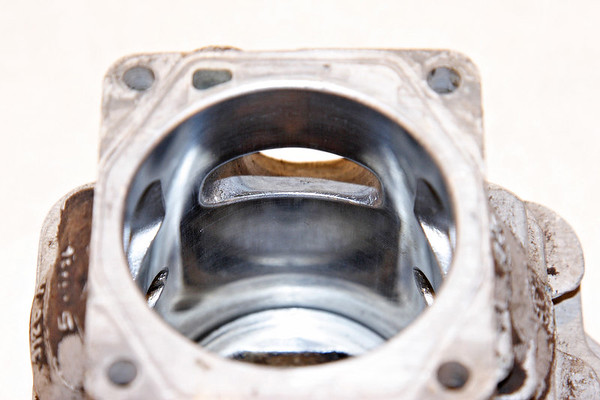

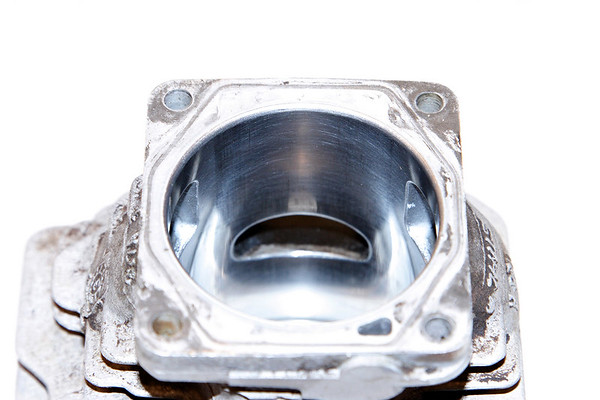

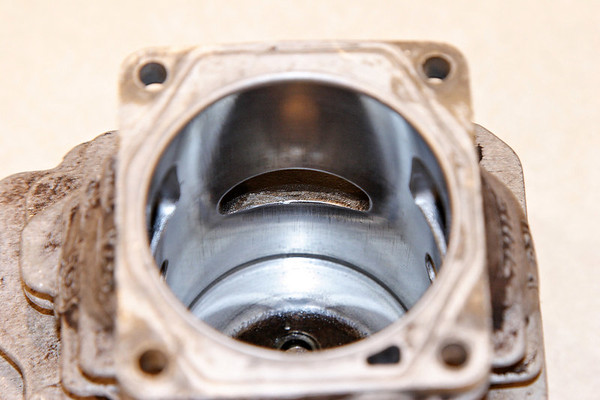

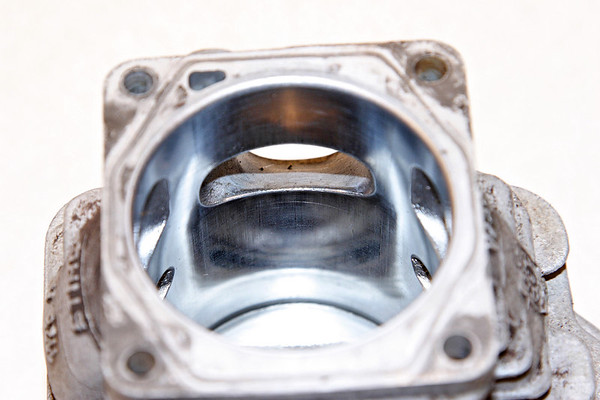

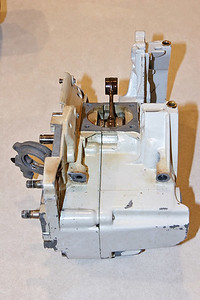

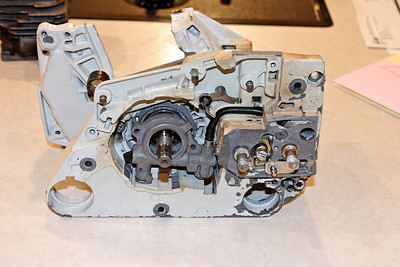

(the Witch told me, but actually, I already new), but saw parts is perfectly OK, unless it is an unplugged motor.......Ekka said:There you go, pretty good.

Computerusers stuff shouldn't be too far behind either.

Hmmm, I think I might have something else to sacrifice to the saw builders bench in the garage ... I'll have a look.

You guys obviously like this stuff but out here parts are a killer and the market small ... like getting rid of second hand bits is near impossible.

Actually if the paint was like and Ameron industrial grade epoxy, the baked and sealed with polymer and he got a couple of extra years out of a saw it would seem like it would be worth it,,,,disandat said:RiverRat,

I was thinking somewhat on the same path. I was thinking they could be sprayed down with teflon paint or maybe a combination of Chromium primer and Teflon. The big problem is getting a scratch. Every time they are used they should be inspected for scratches and the spot treated. Lots of labor there.

RiverRat2 said:But on the flip side, iEkka may look @ is as being an accepted cost for doing business,,,,and besides look at all the nice parts we get for shipping

Ekka said:I didn't think there'd be enough magnesium to actually burn like that .... chuck one in the camp fire next camping trip.

Enter your email address to join: