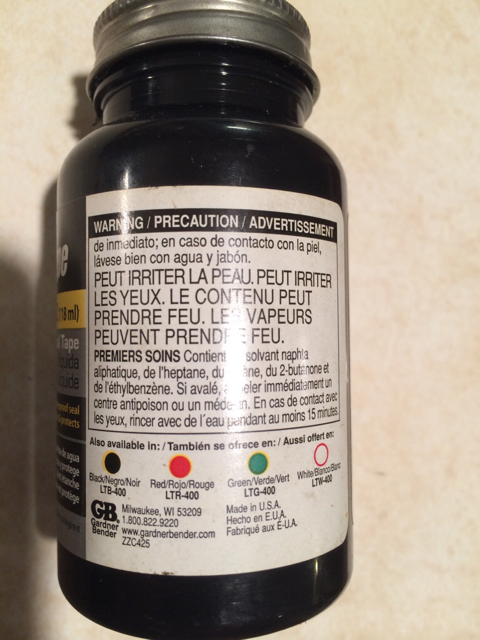

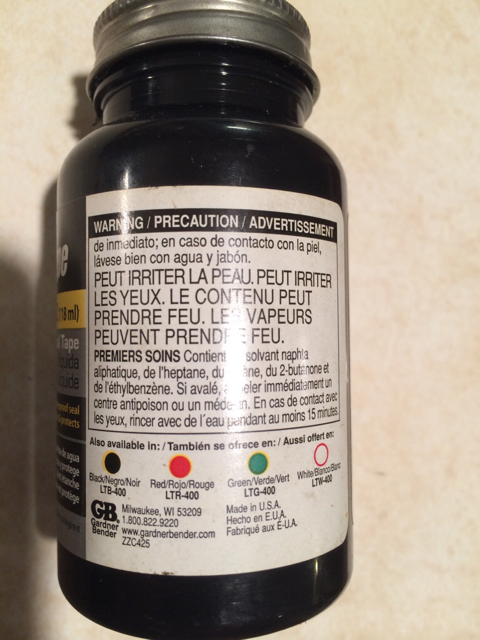

I find this stuff invaluable for mending chaffed wire leads and just pasting down things.

The thing to use to glue in plug leads to a coil.

I need to get another bottle from Lowes.

The thing to use to glue in plug leads to a coil.

I need to get another bottle from Lowes.