I've been in the garage all evening! LOOOOOOTTTTSSSS of pics coming.

LOOOOOOTTTTSSSS of pics coming.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Solo Twin....FINALLY!!!

- Thread starter blsnelling

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Wannabe123

ArboristSite Operative

Cool thread, love the saw. I think I want one just to watch people scratch their head at the words "solo twin" put together.

CR500

Diesel, Snowmobile, & Chainsaw Technician

Thinking of getting a banshee instead of a water-x sled/project for the summer

All this banshee talk leads me to the Quadzilla, It may have not pulled RPMs but it surely was a monster... something about 500cc od power always gets me. Even when it comes to sleds as of late I've been more attracted to 600-700cc power plants. Especially a stock 600 factory race buggy lol

Sent from my non internal combustion device.

All this banshee talk leads me to the Quadzilla, It may have not pulled RPMs but it surely was a monster... something about 500cc od power always gets me. Even when it comes to sleds as of late I've been more attracted to 600-700cc power plants. Especially a stock 600 factory race buggy lol

Sent from my non internal combustion device.

This is going to be a ride, guys. I've got 91 pics to share. Normally, I wouldn't post them all, but due to how rare these are and the lack of info on them, I'm going to share them all.

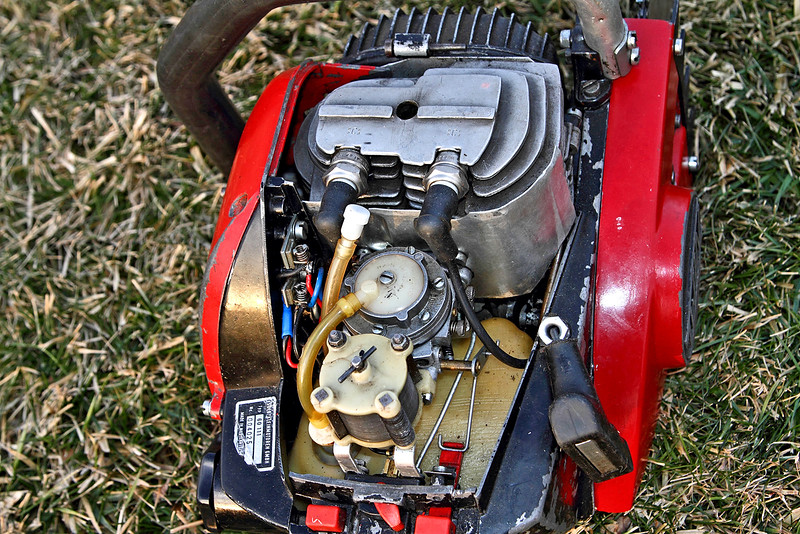

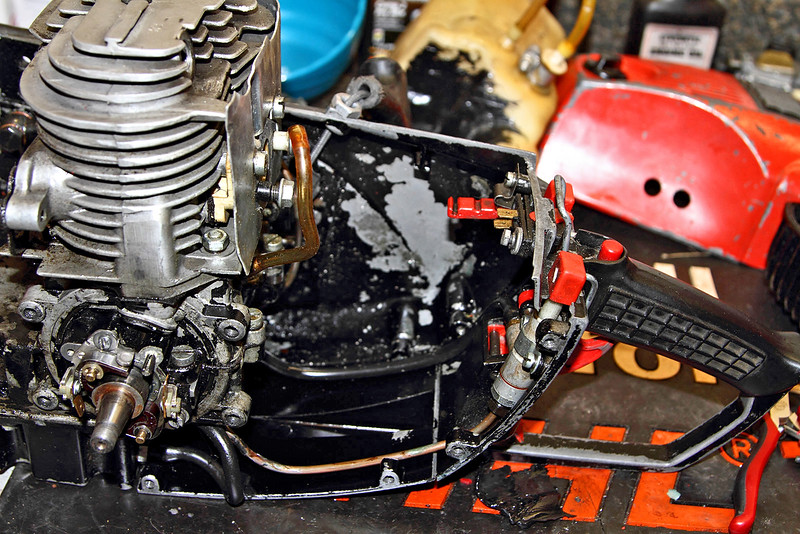

Here she is, fresh out of the box.

Here she is, fresh out of the box.

I did not plan to go where I ended up going with this saw tonight, but here we go. When I start on something, it's hard for me to stop, lol. I'm going to be sharing the good...the bad...and the ugly!

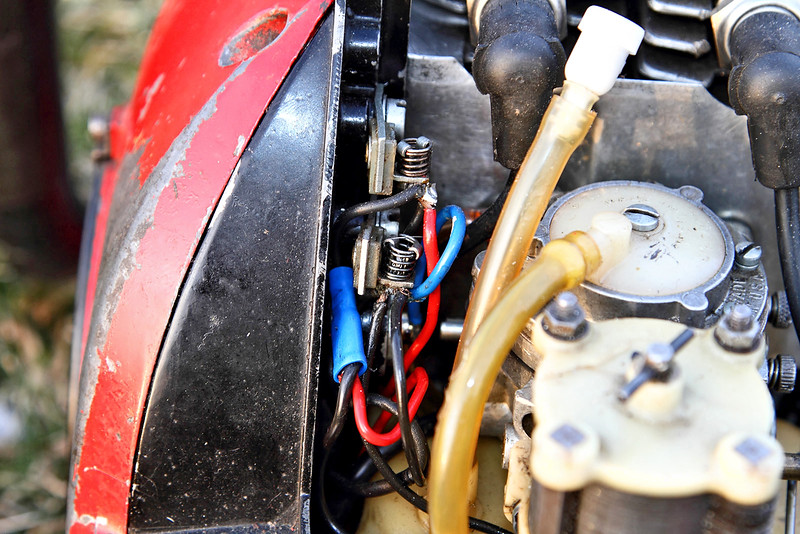

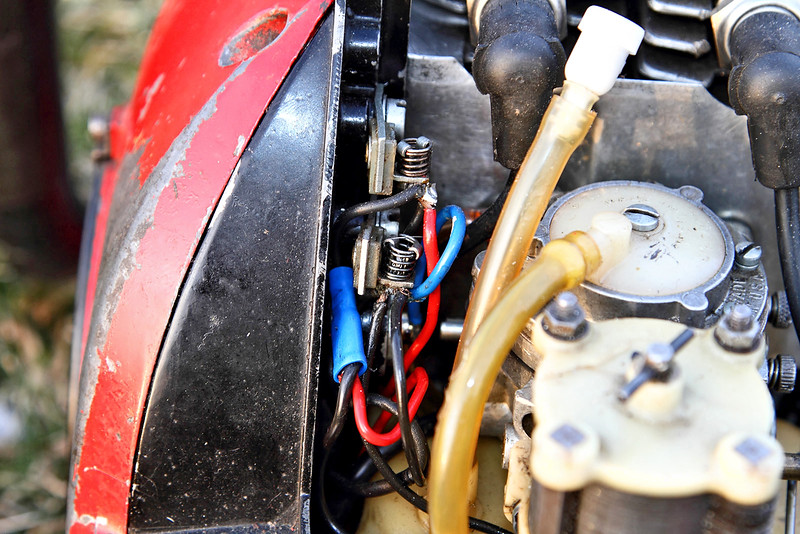

I knew I had some electrical issues. Here's the beginning of it.

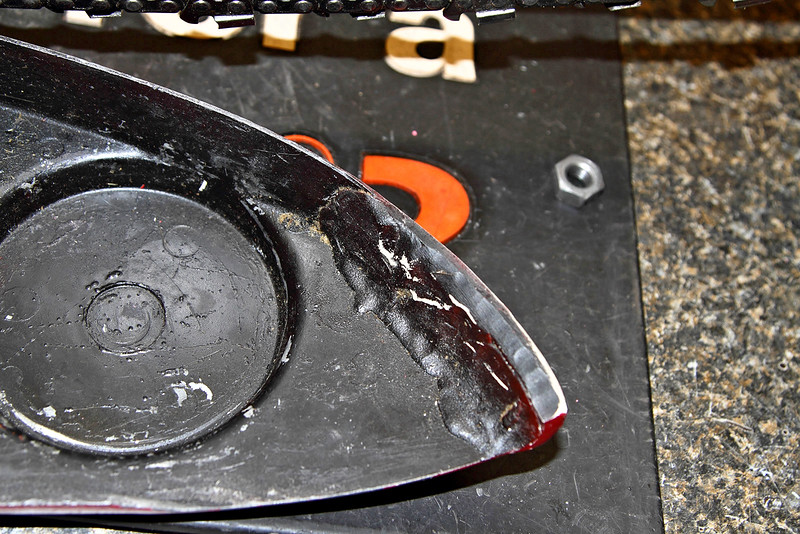

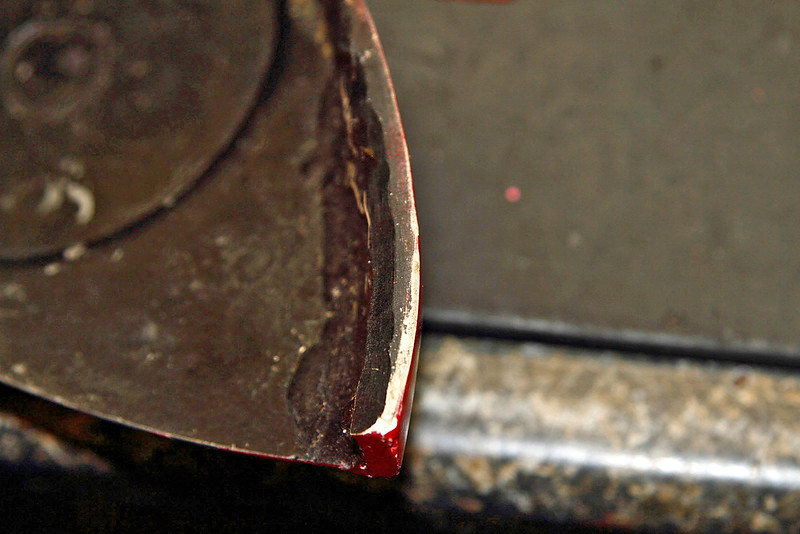

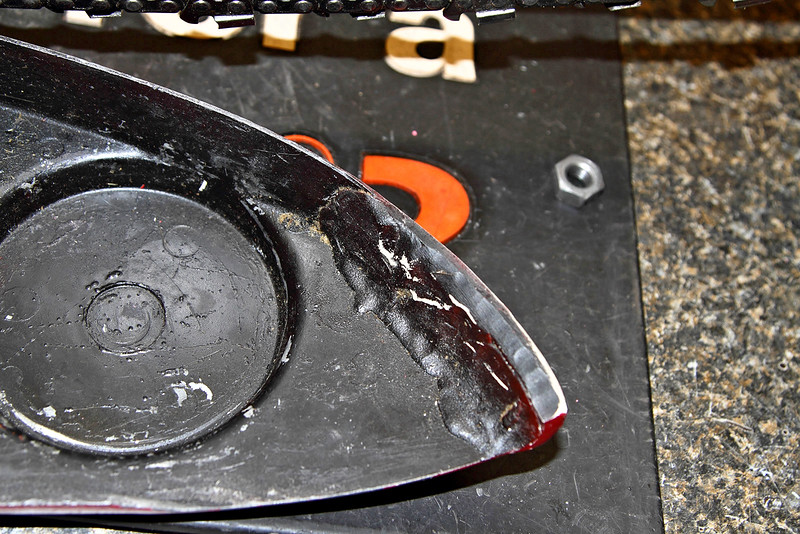

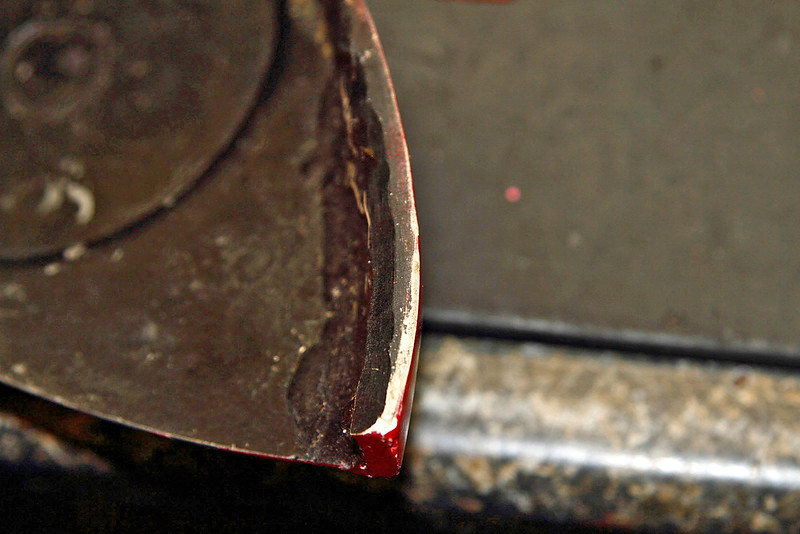

The recoil cover has been repaired. My main concern is that it appears metal is missing, not just cracked.

The cylinder cover hinge has been previously repaired as well.

I knew I had some electrical issues. Here's the beginning of it.

The recoil cover has been repaired. My main concern is that it appears metal is missing, not just cracked.

The cylinder cover hinge has been previously repaired as well.

- Joined

- Jan 11, 2014

- Messages

- 3,379

- Reaction score

- 3,997

I can't wait to hear that saw in a video. Exceptional saw Brad, congratulations.

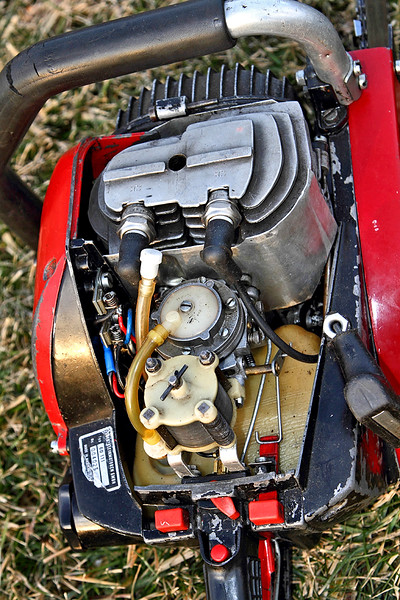

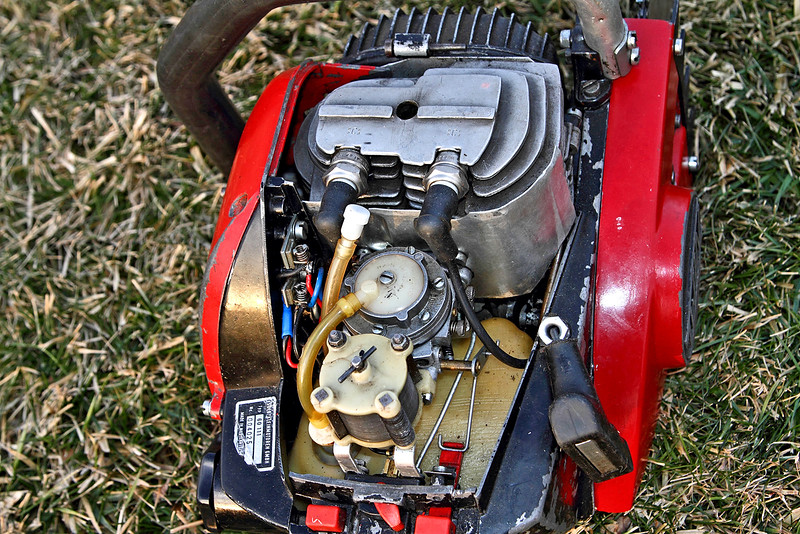

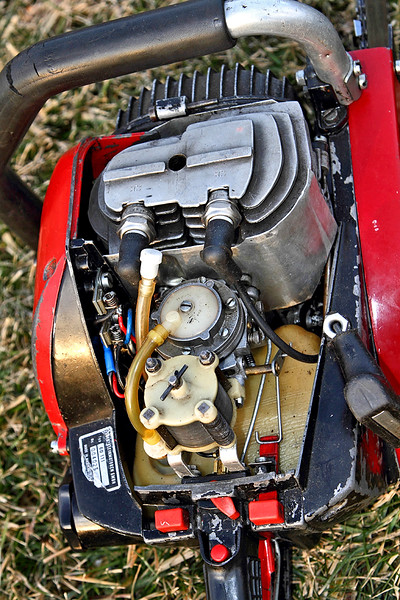

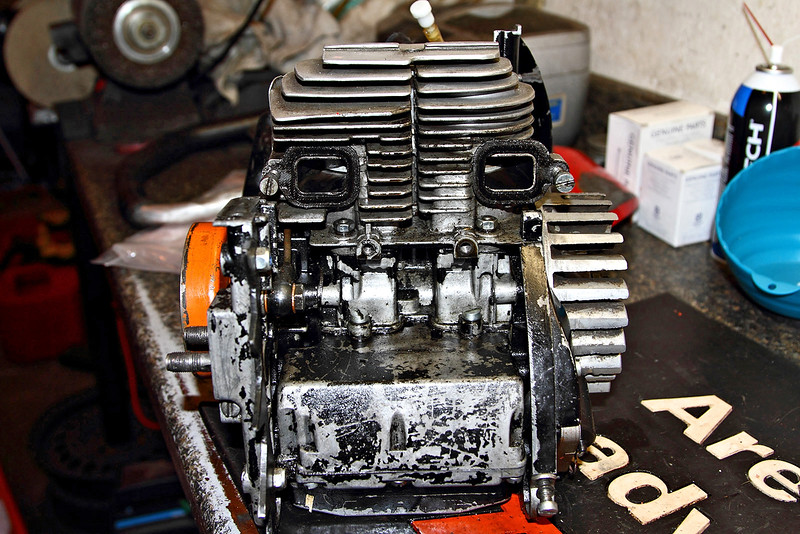

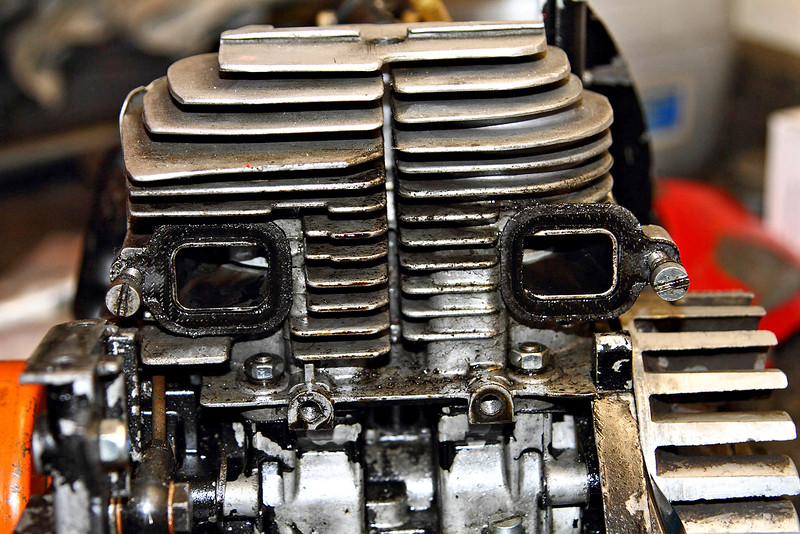

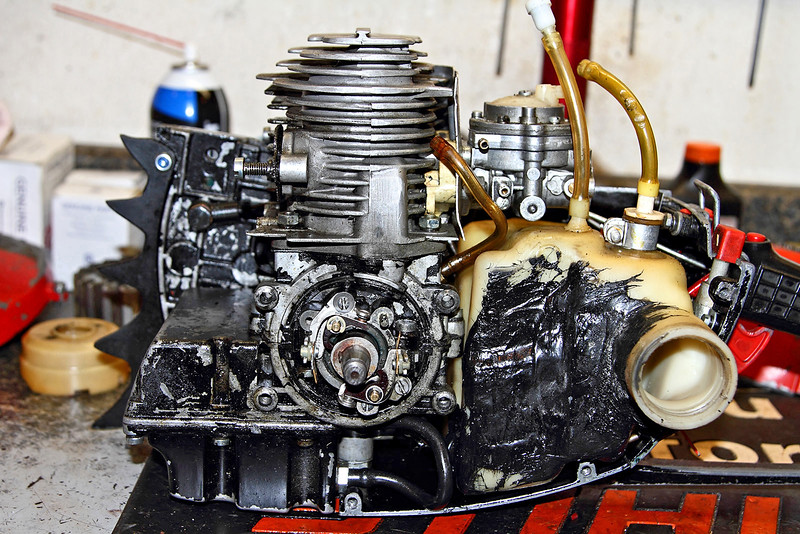

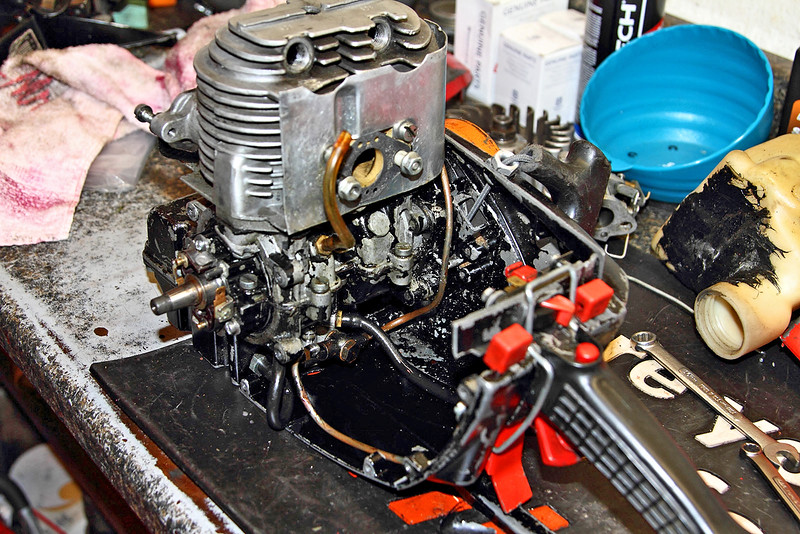

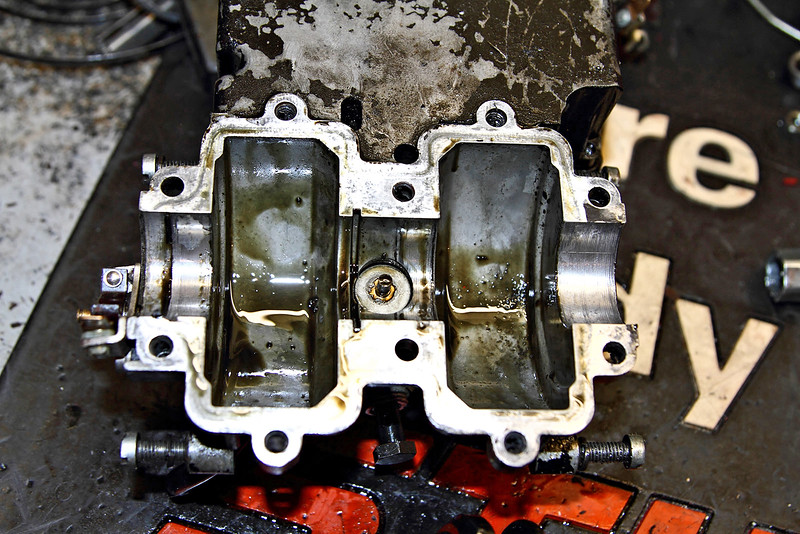

Here I have removed the muffler cover. Those are the exhaust port on both sides. They exit from the outside corners of the cylinders.

This is inside the muffler cover. The exhaust travels through the pipes before exiting.

This is the back side of the muffler backing, where it mates up to the cylinders.

So far, so good.

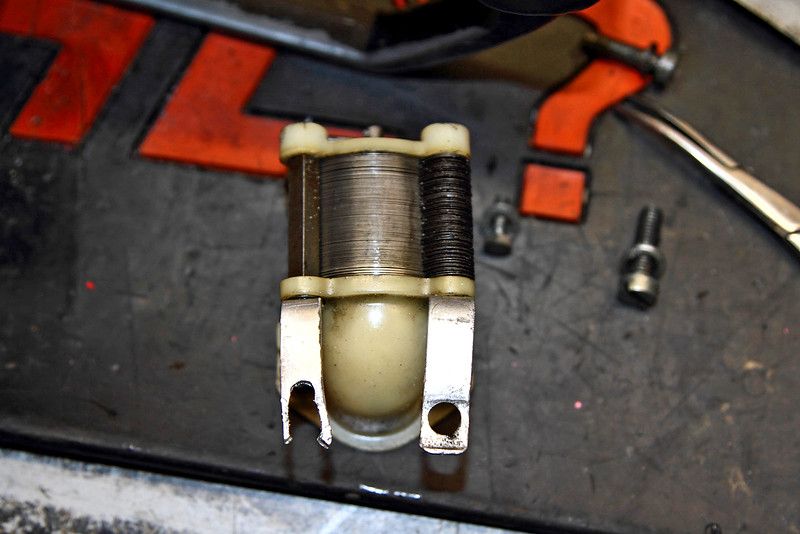

This is the most unique air filter I've ever seen! It's stacked metal plates.

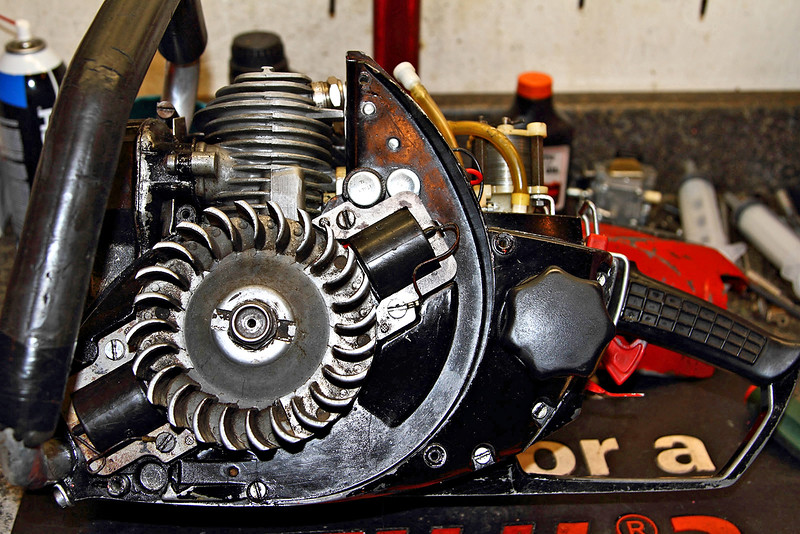

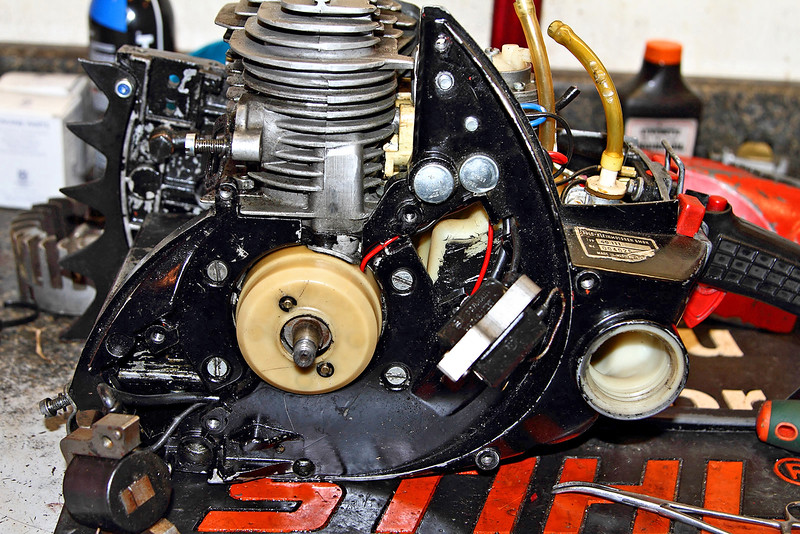

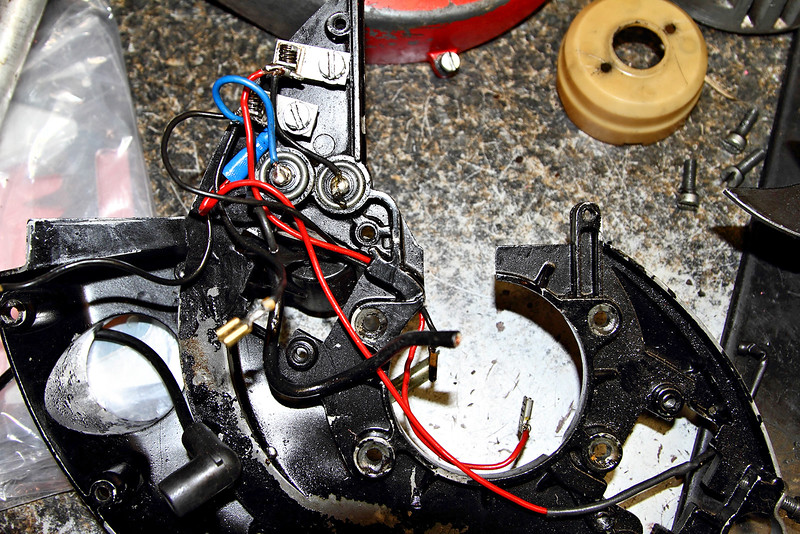

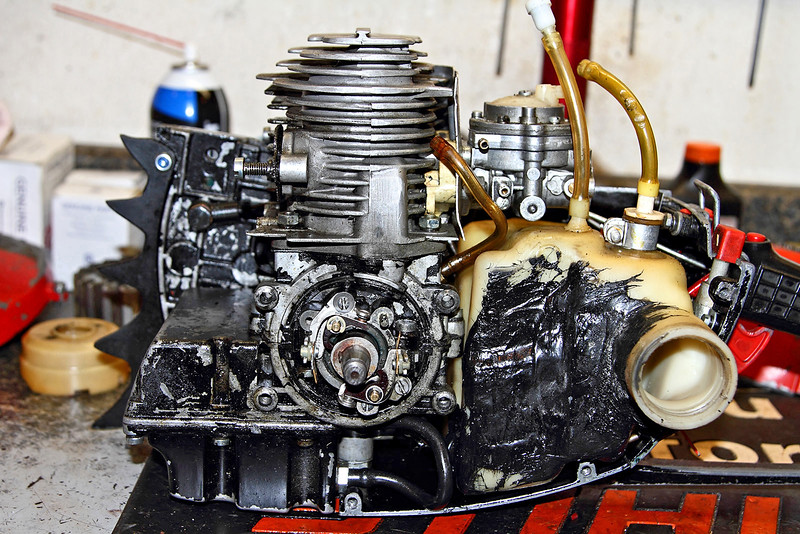

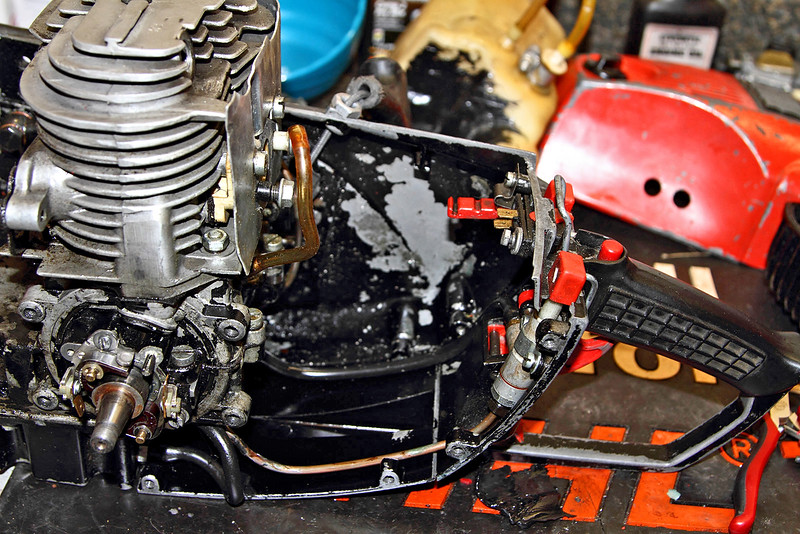

Here I'm removing the coils and side of the saw. I know I've got to remove the fuel tank, due to known leak issues.

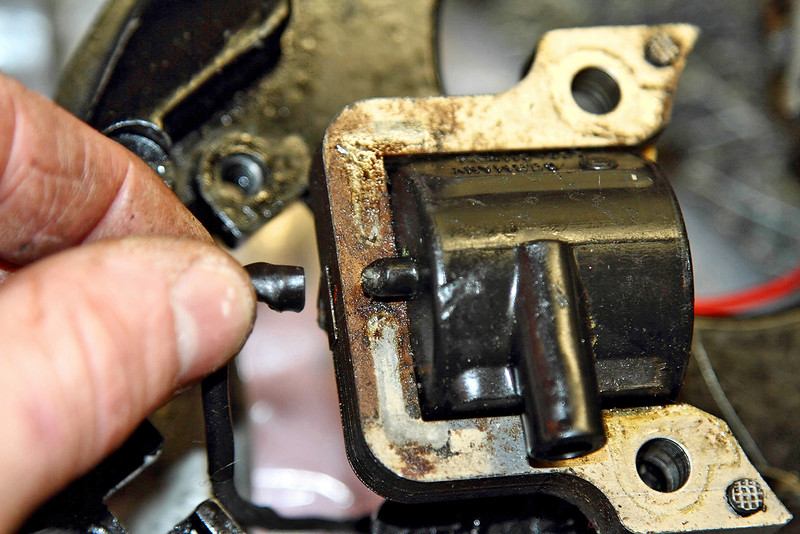

Uh oh. More trouble. This wire is broken off flush with the front coil.

What a rats nest! Should clean up easy enough though.

More trouble.

That's going to be a while!I can't wait to hear that saw in a video. Exceptional saw Brad, congratulations.

Here's a little service reminder for you. Silicone is not fuel proof!

It's out!

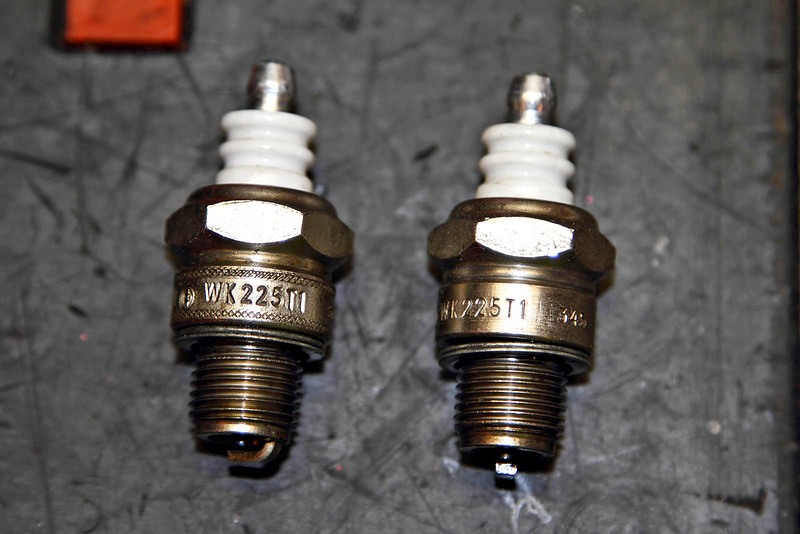

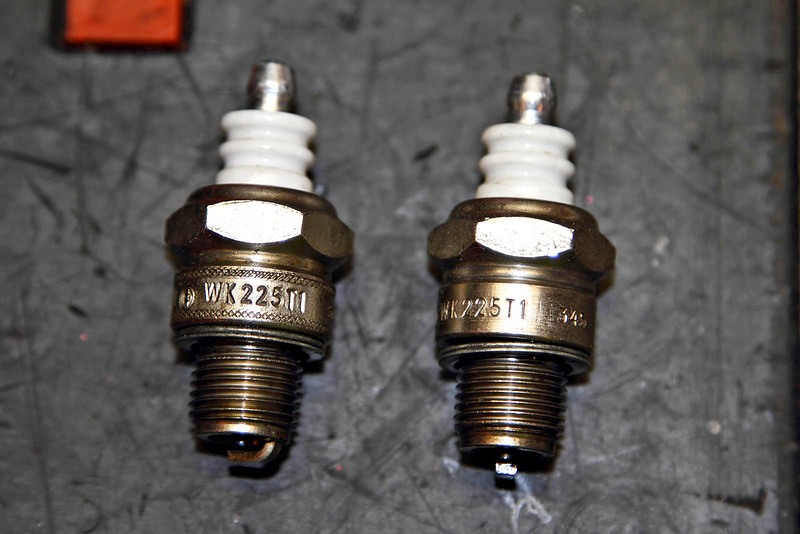

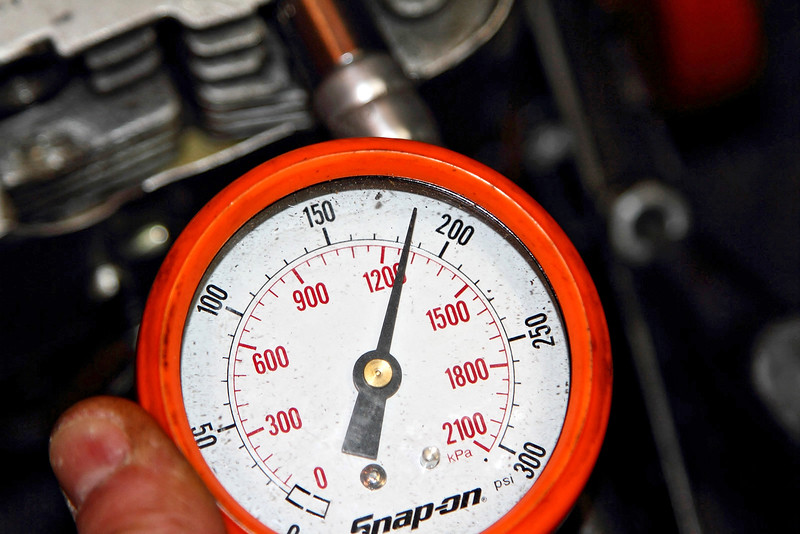

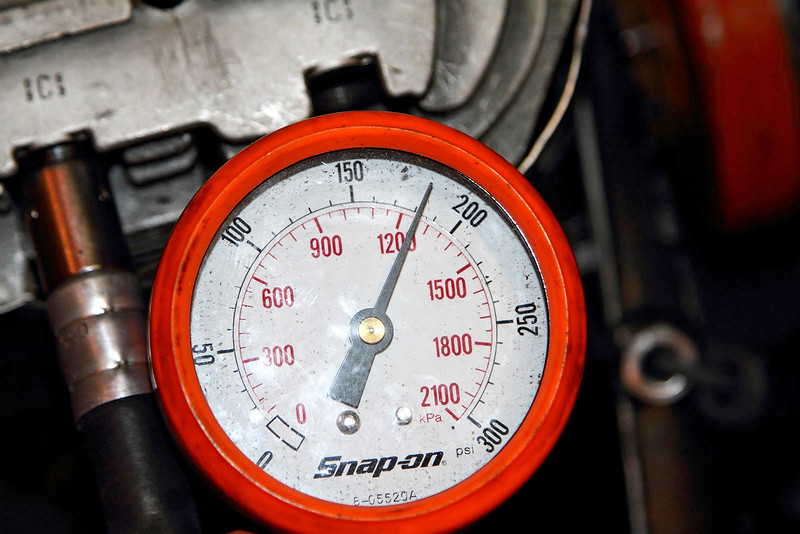

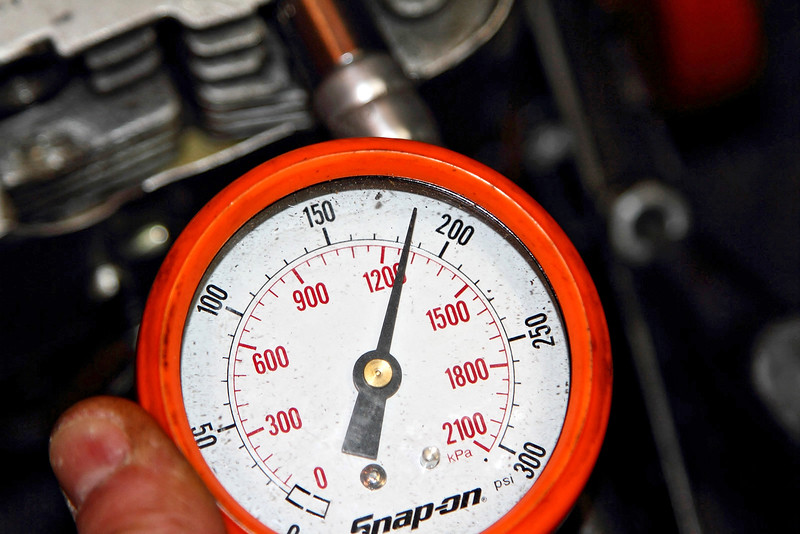

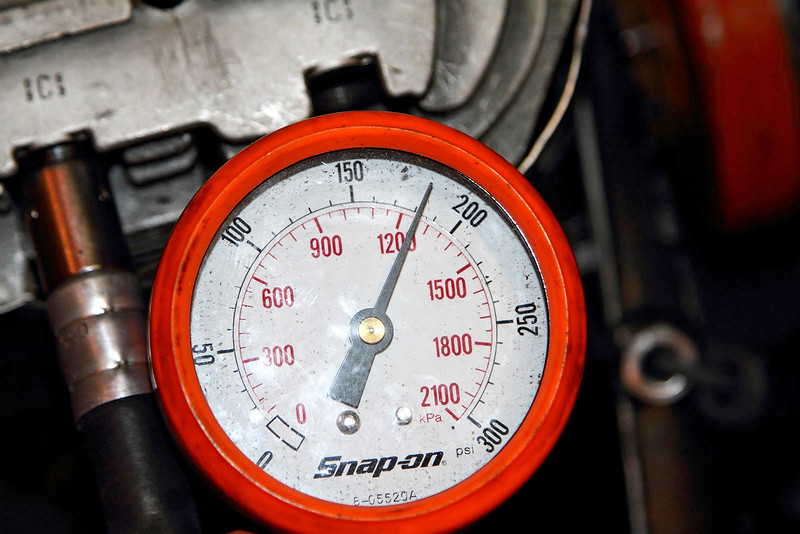

Well, here's a good sign!!!

It's out!

Well, here's a good sign!!!

- Joined

- Jan 11, 2014

- Messages

- 3,379

- Reaction score

- 3,997

It will be worth the wait. YouTube could use a few more videos of these in action. The audio is just so unique. One video from Germany sure made the saw seem aggressive . Its a definite 6 cube club saw.

. Its a definite 6 cube club saw.

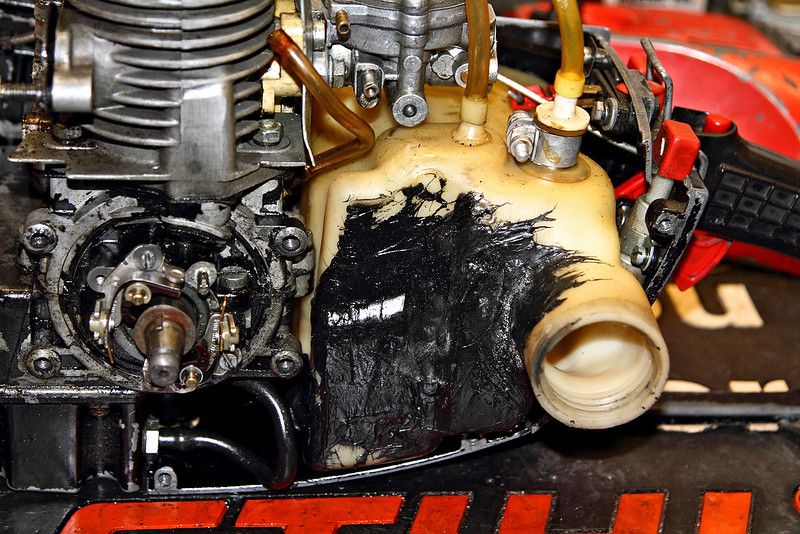

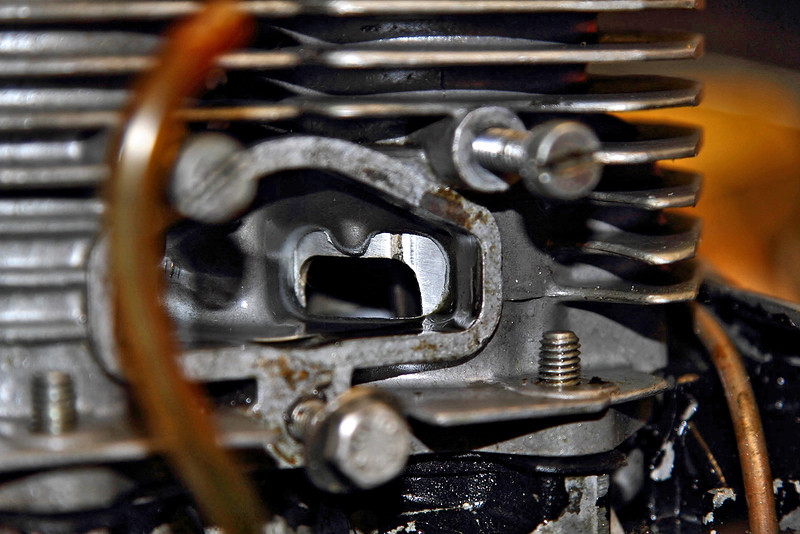

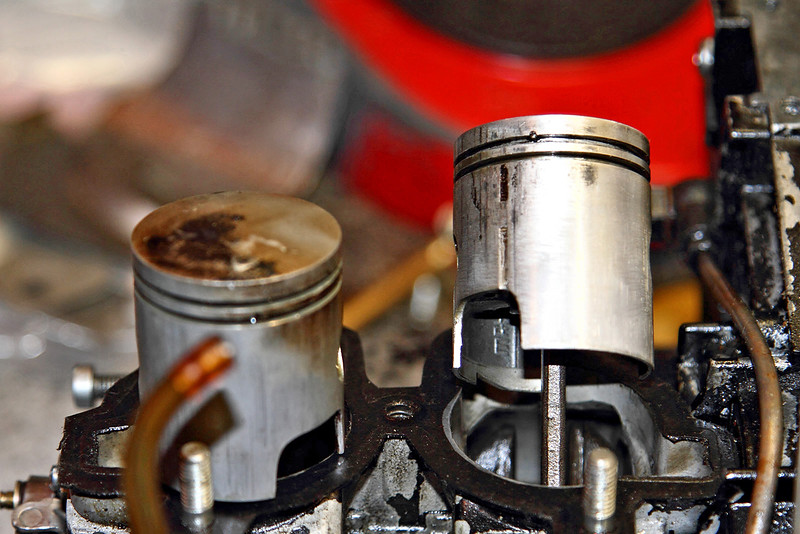

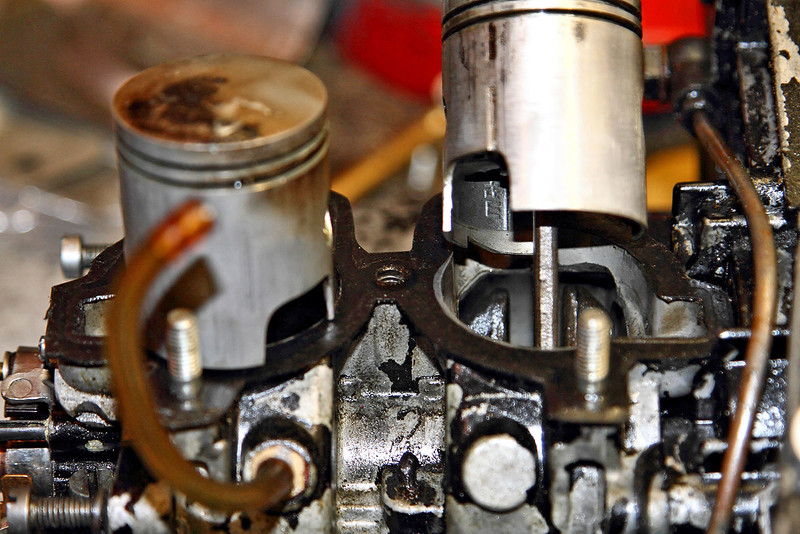

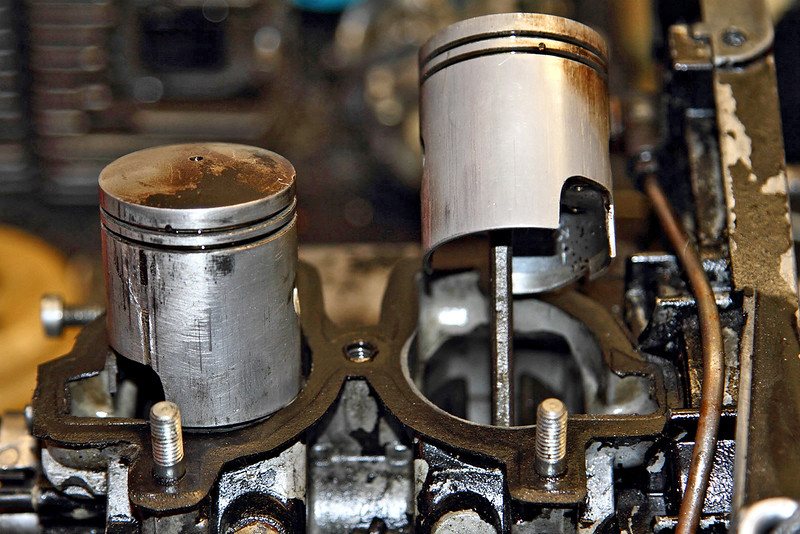

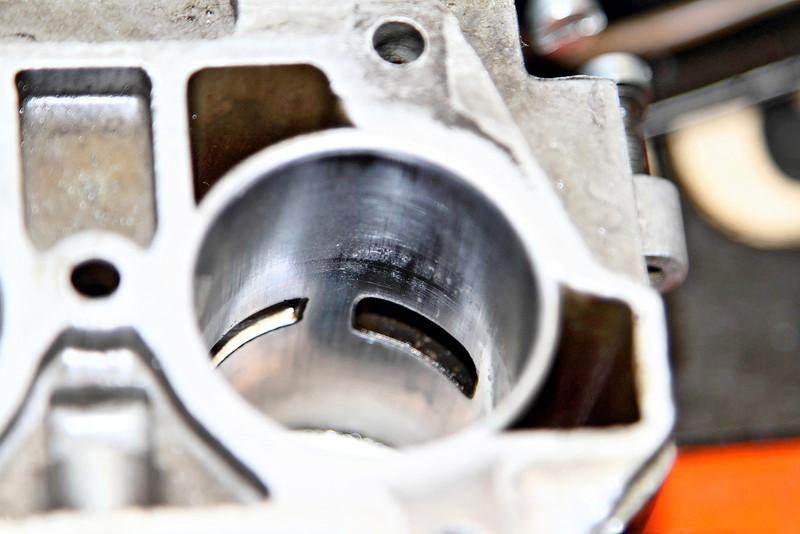

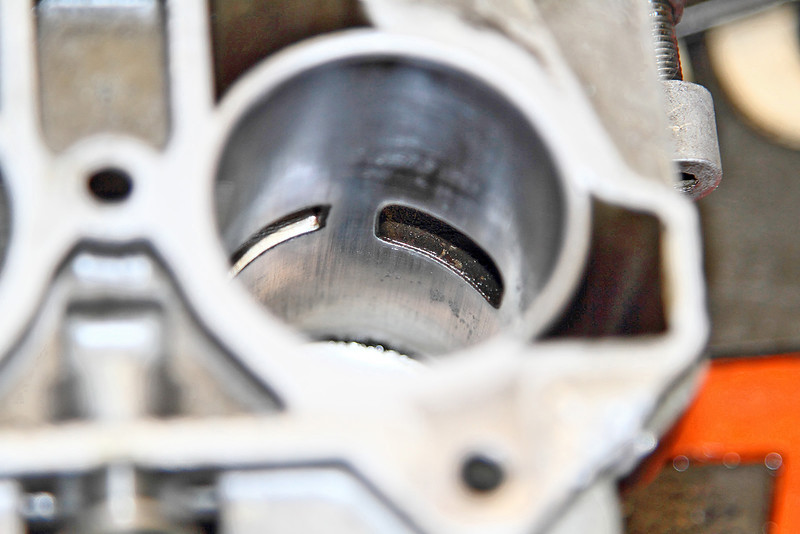

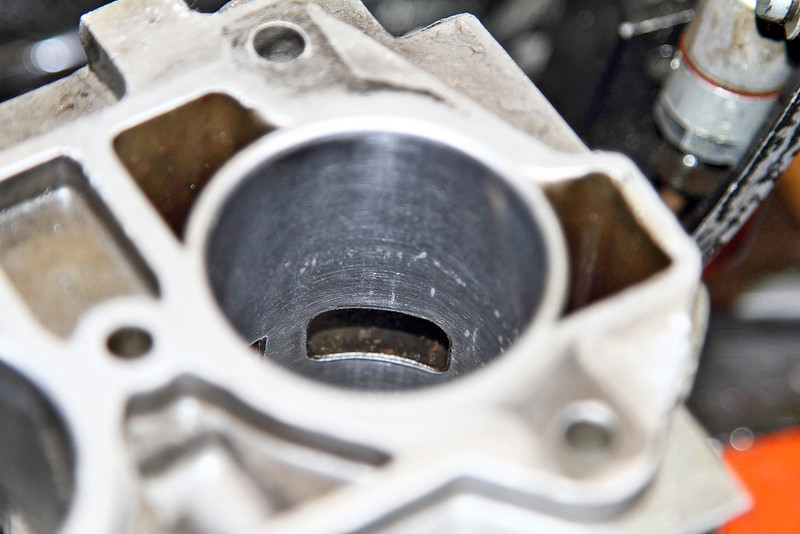

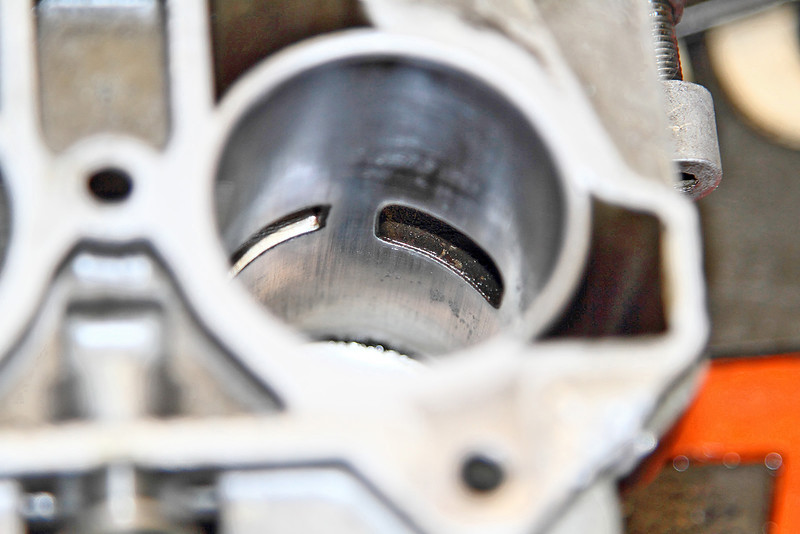

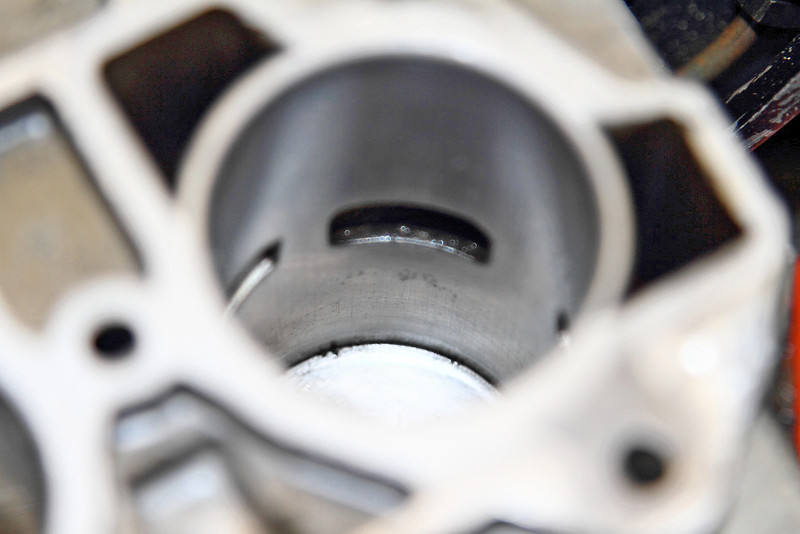

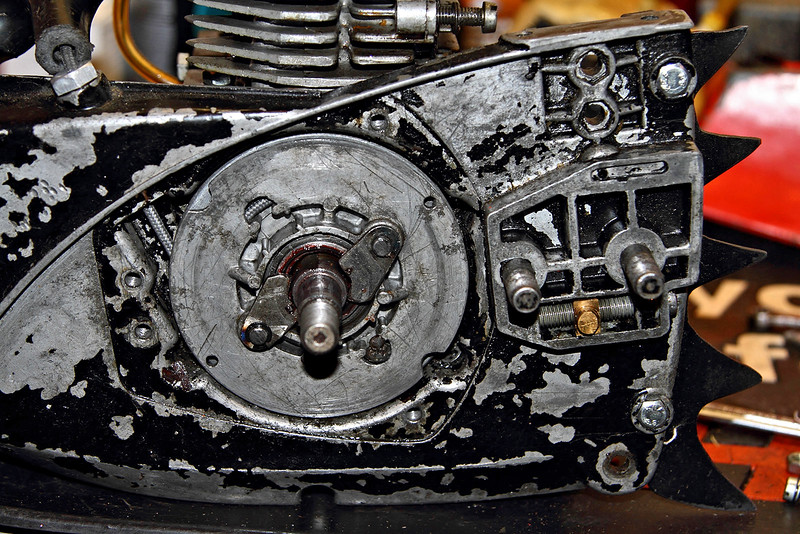

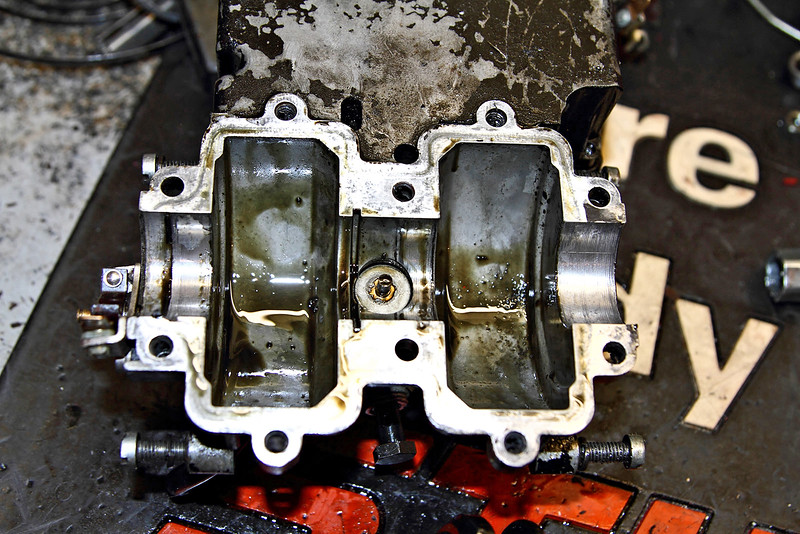

Uh oh! This isn't looking so good after all! This was certainly not expected. I know at this point that this saw is coming apart.

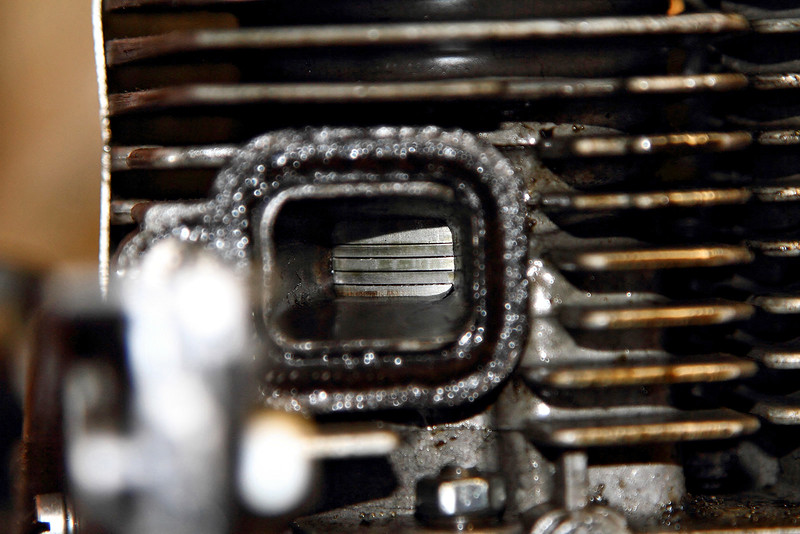

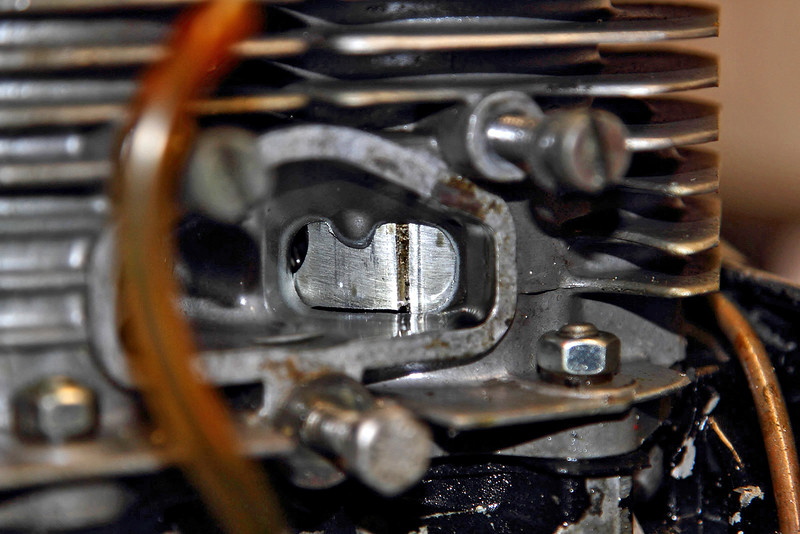

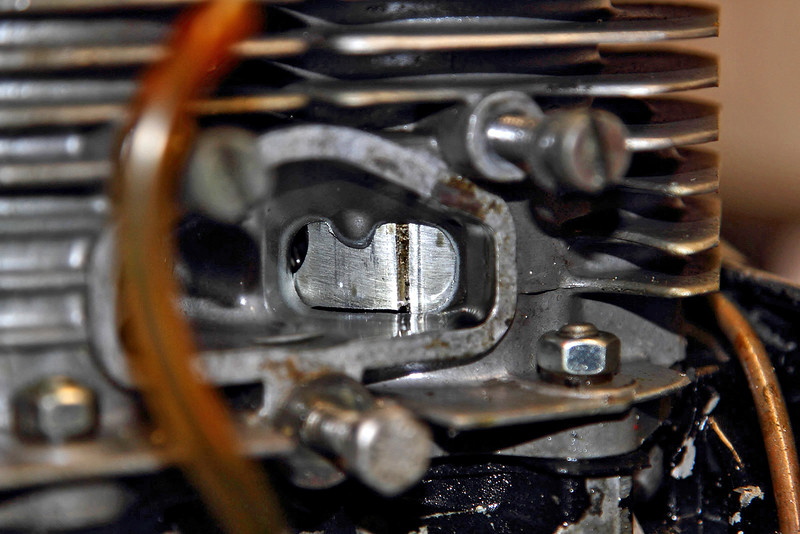

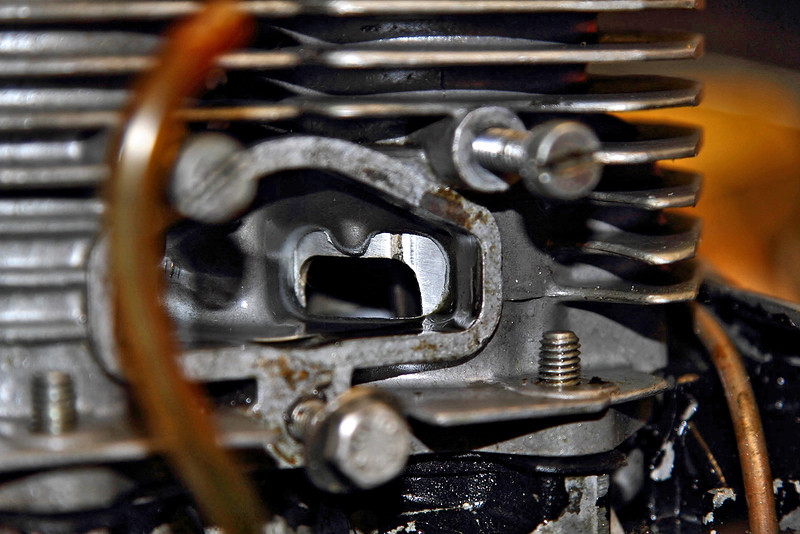

What's up with this cut out?

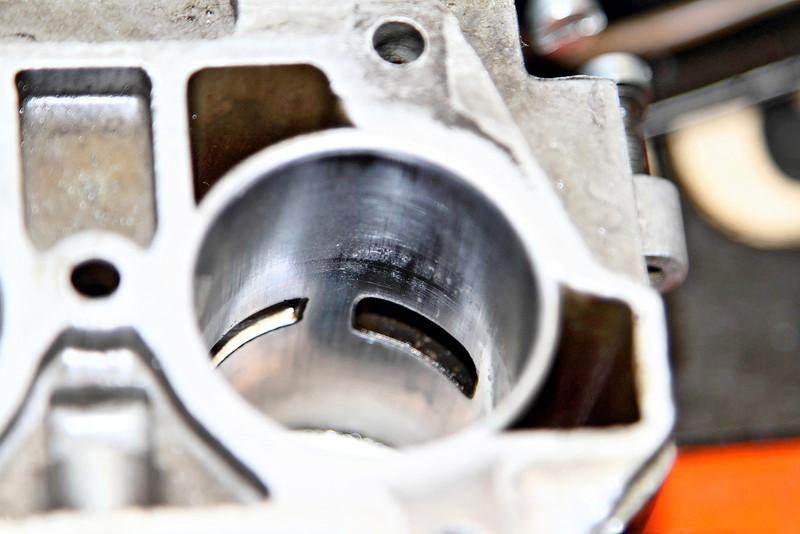

Uhg. This isn't looking so good. Someone has been in here, and in here recently!

What's up with the C and the arrows?

These arrows are pointing towards the inside corners of the cylinder.

What's up with this cut out?

Uhg. This isn't looking so good. Someone has been in here, and in here recently!

What's up with the C and the arrows?

These arrows are pointing towards the inside corners of the cylinder.

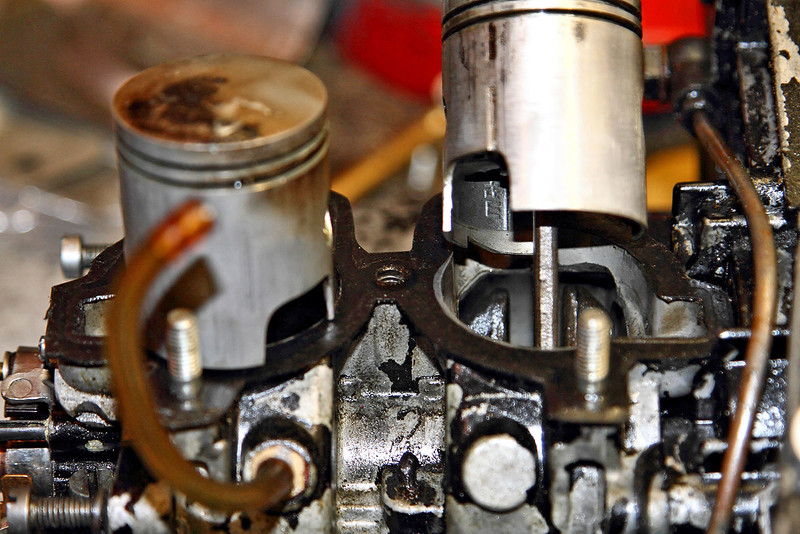

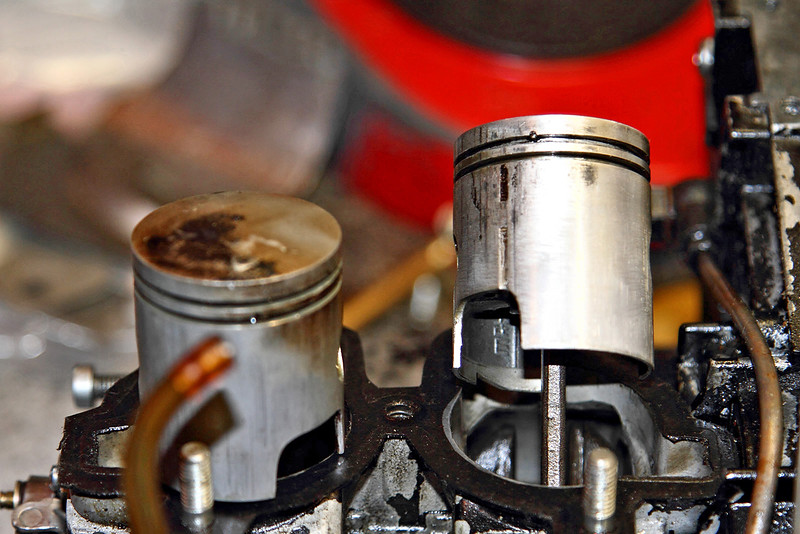

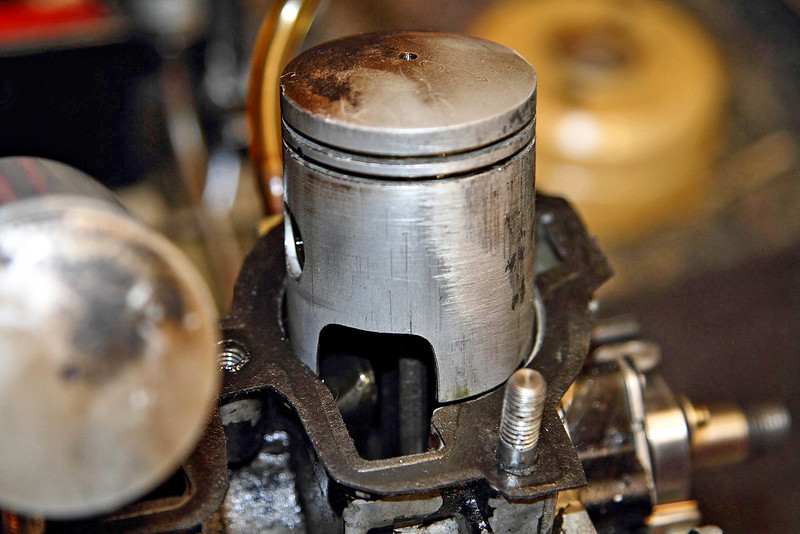

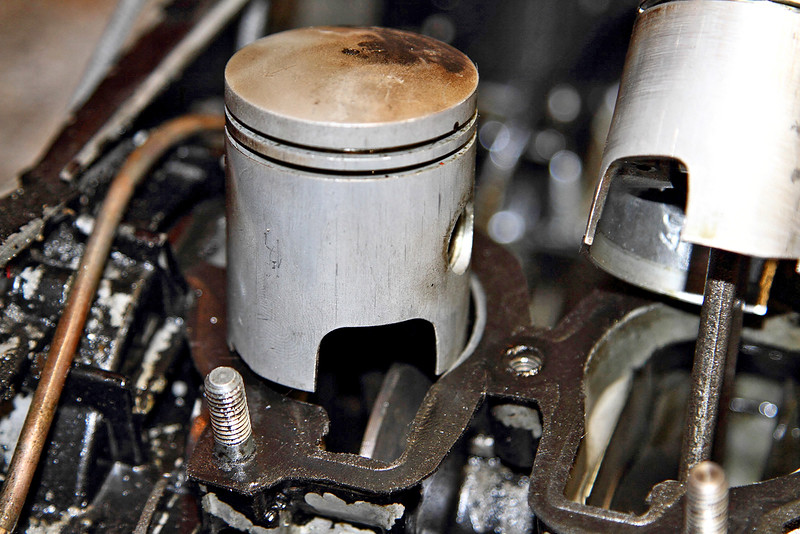

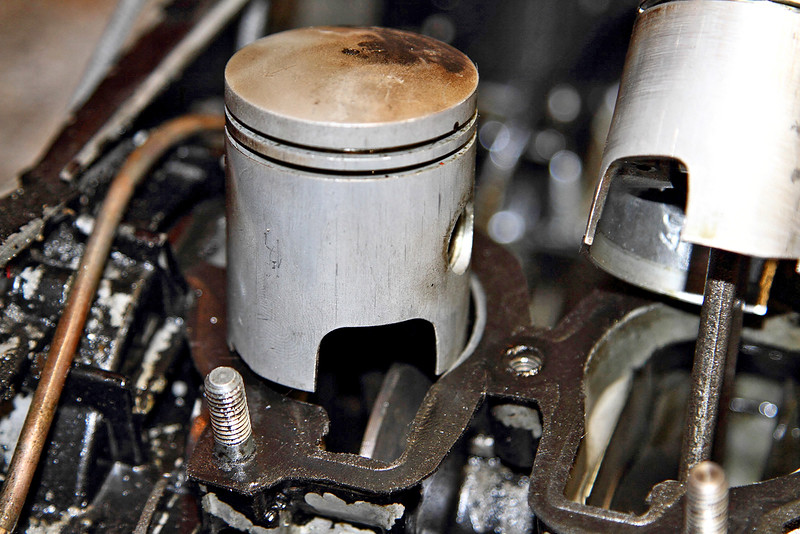

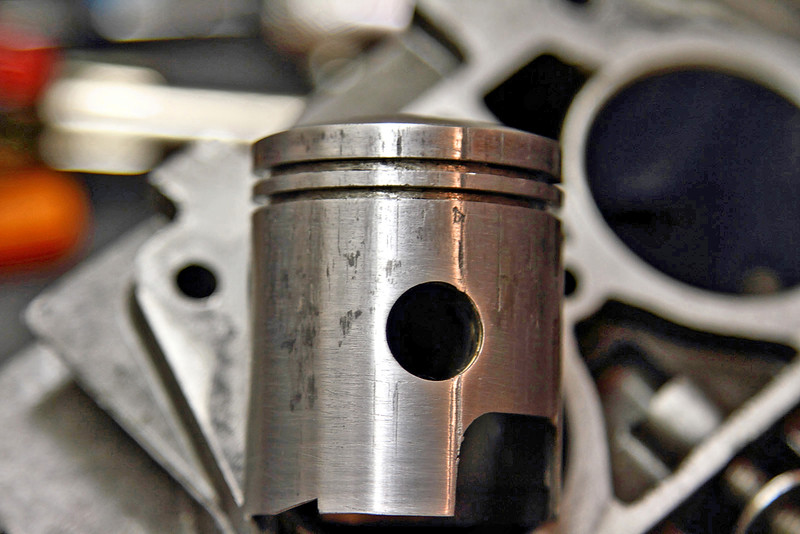

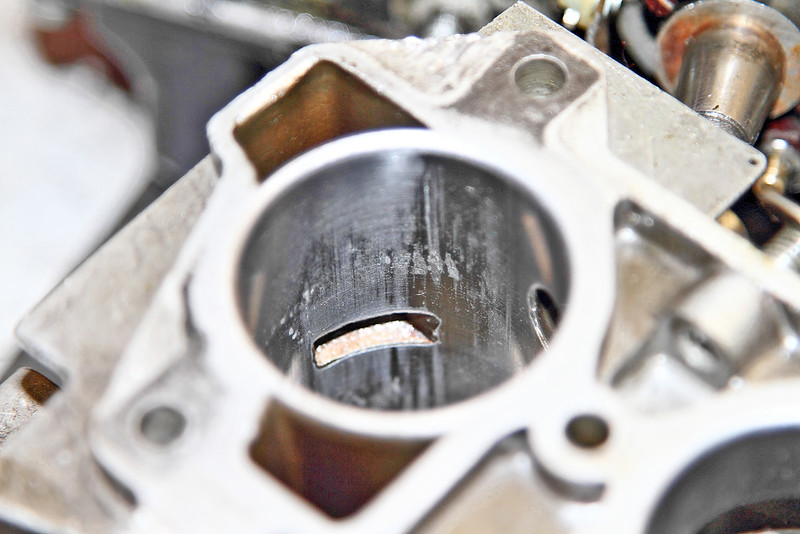

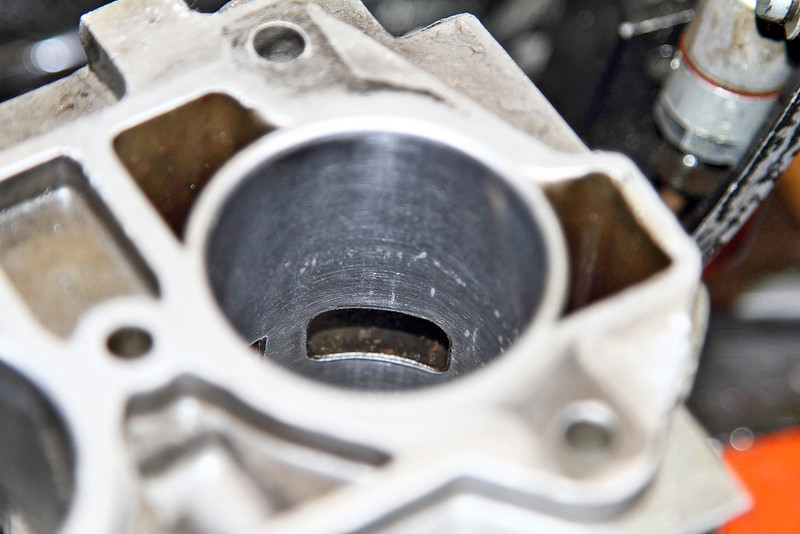

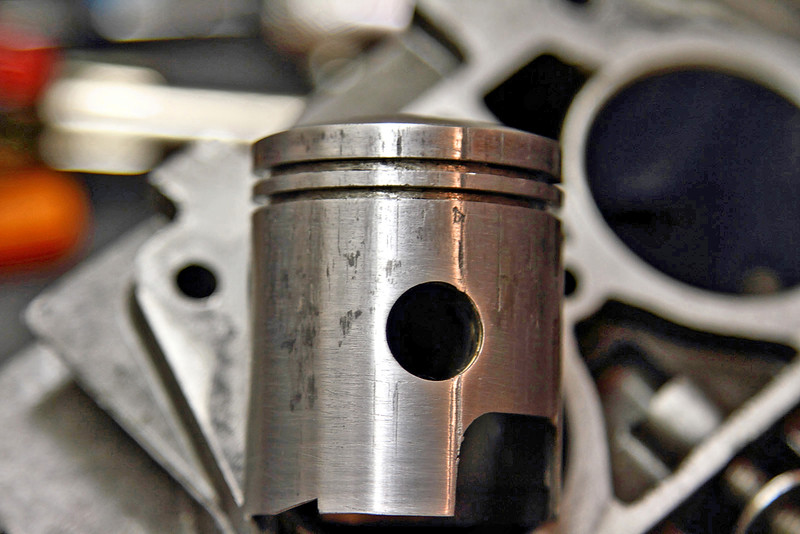

Here's some closeups of the piston. The sanding you see was already done when I pulled it apart. There are no high spots. While not pretty, this piston is serviceable. You do what you have to when working with old relics.

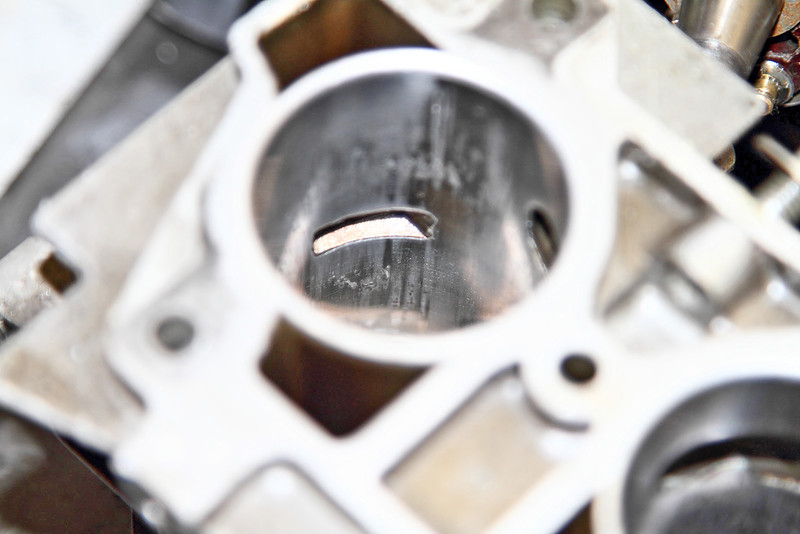

A little studying revealed someones HUGE mistake. It's very obvious now why the last person to work on this saw could not get it running right. They bought it in this condition and were simply trying to make it run. Quite honestly, it amazes me that it ran at all. THE PISTONS WERE IN THE WRONG CYLINDERS, and they are not the same. Those cutouts are intended to clear the transfer ports in the cylinder. Instead, they were opening both the intake and exhaust ports! In effect, this would be like dropping the intake port timing by the amount of that cutout! The exhaust was free porting badly at TDC. That also meant the transfers couldn't open properly. When the saw was apart for repairs, the pistons were put back in wrong. It's no wonder this saw was sold a couple times before it made it to me. I'm just glad that I'm one to go through a saw before putting it to use. This would have caused me to pull the rest of my hair out, had I not torn the saw apart and found it.

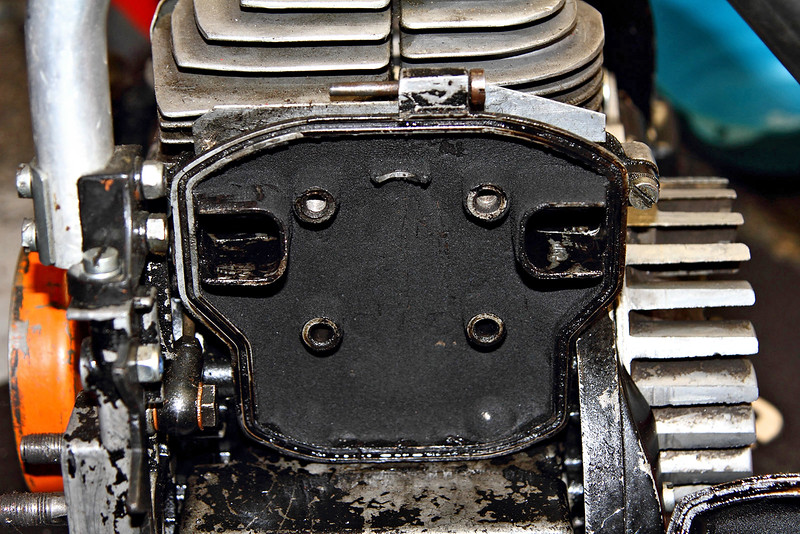

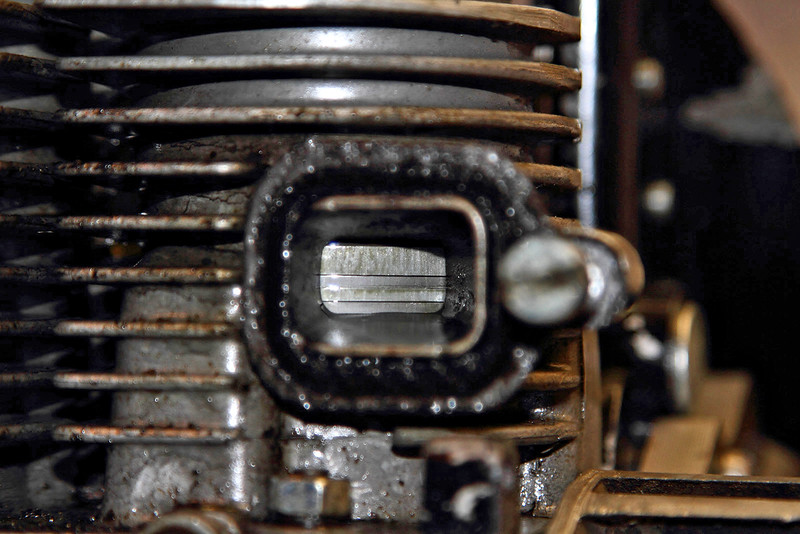

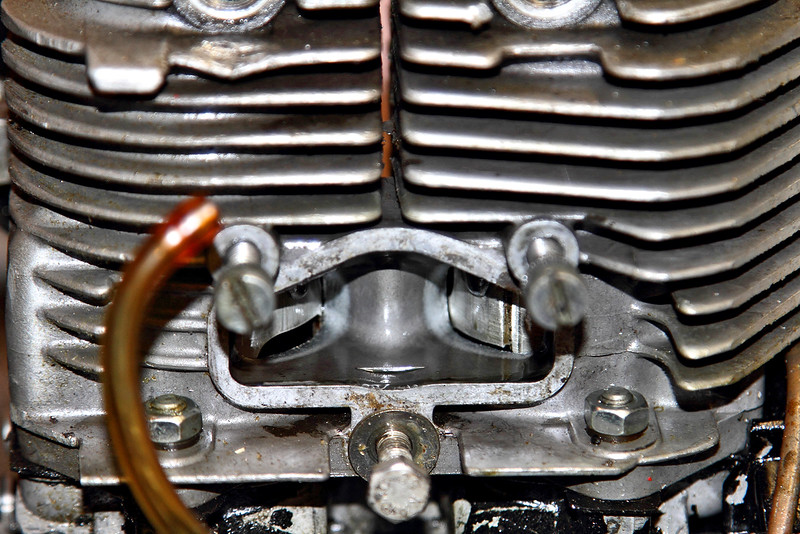

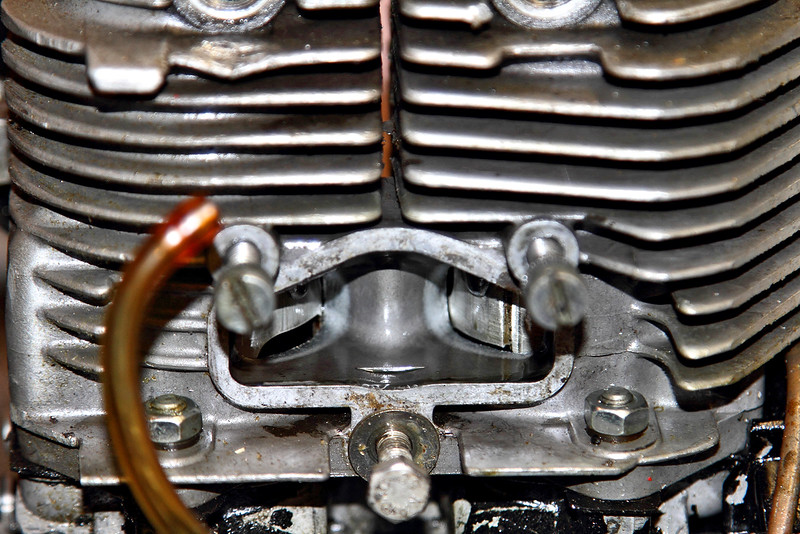

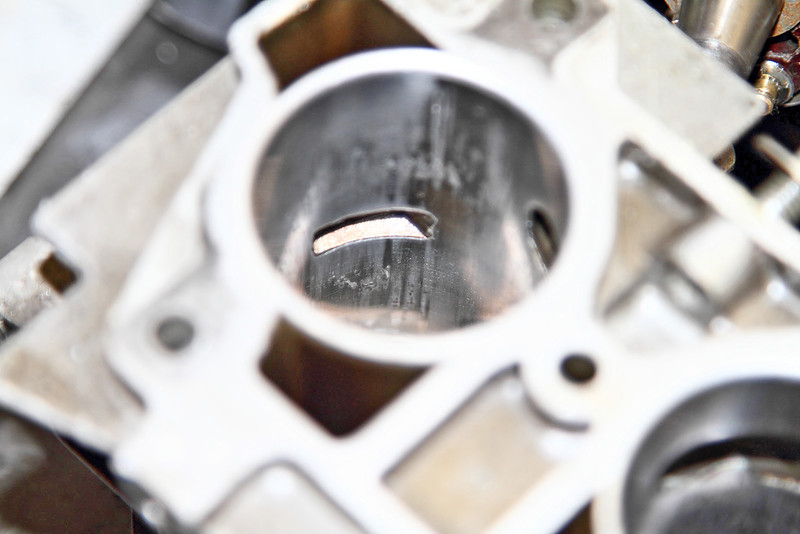

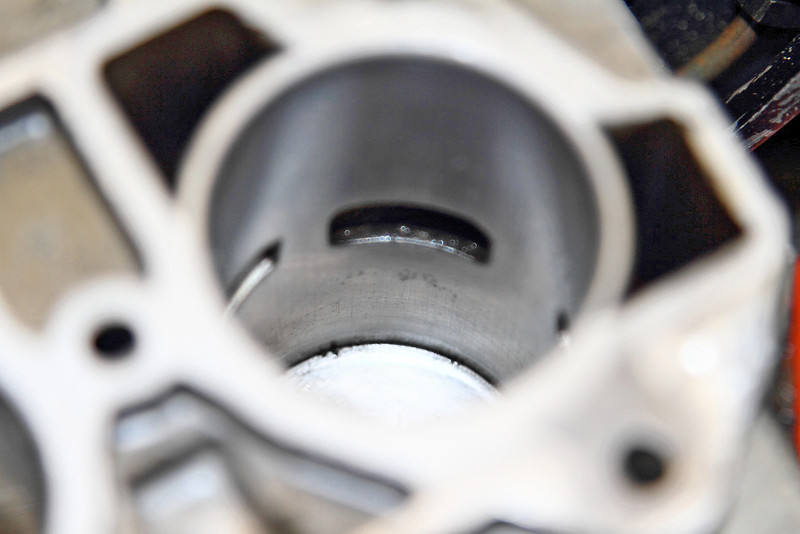

Here I have put the pistons were they belong. Those arrows now point to the outside corners, directly at the exhaust ports. The cutouts now line up with the transfer port, both in the case, and in the cylinder.

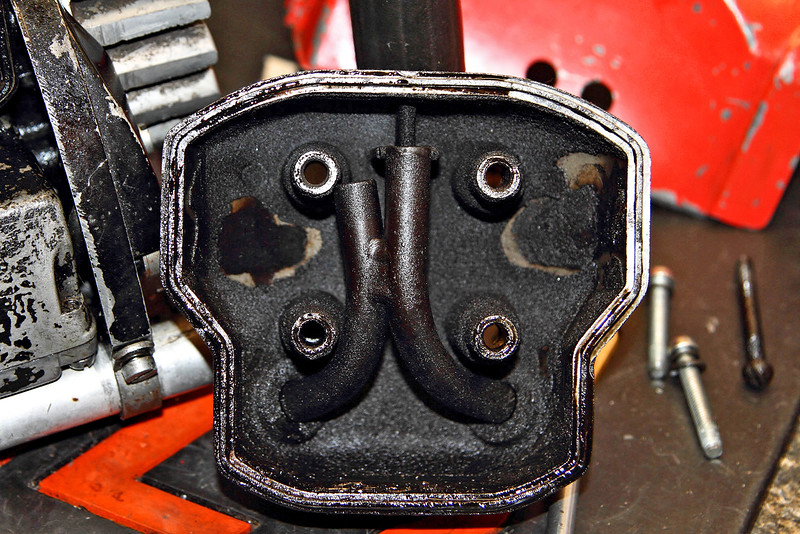

See how that matches up with the transfer duct? The transfer port in the cylinder is directly above this.

Here I have put the pistons were they belong. Those arrows now point to the outside corners, directly at the exhaust ports. The cutouts now line up with the transfer port, both in the case, and in the cylinder.

See how that matches up with the transfer duct? The transfer port in the cylinder is directly above this.

Wannabe123

ArboristSite Operative

All this banshee talk leads me to the Quadzilla, It may have not pulled RPMs but it surely was a monster... something about 500cc od power always gets me. .

Banshees rip and are tons of fun, but I ride lots of technical, tight trails and like the four strokes for that kind of work, just dig that low end. That being said in a pit nothing beats a banshee for sheer giggles. HOWEVER, a quadzilla 500 is just plain maniacal. Only rode one. Think I'm good.

BAck on topic I love the pics. Amazing what kind of work goes into making a unique high quality machine of any kind. Keep em coming!

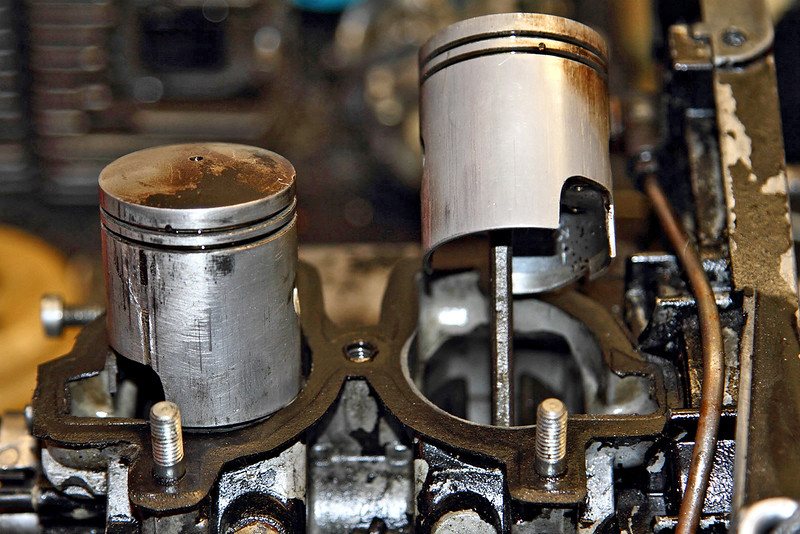

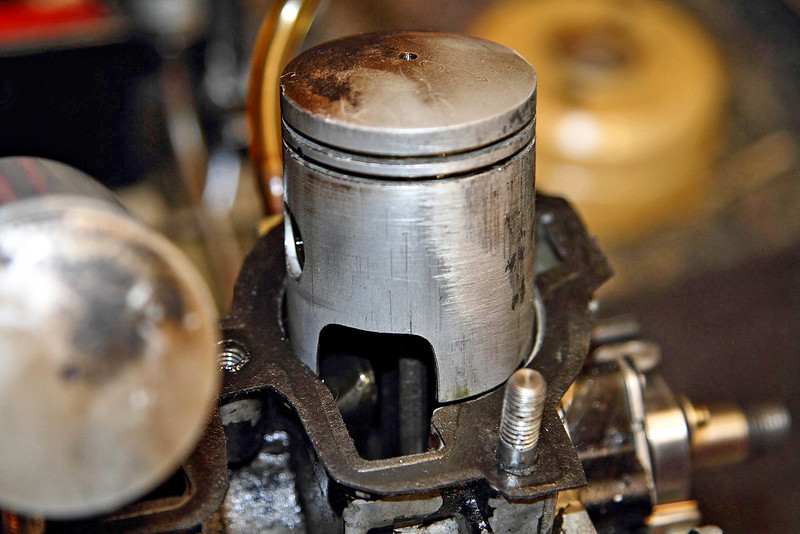

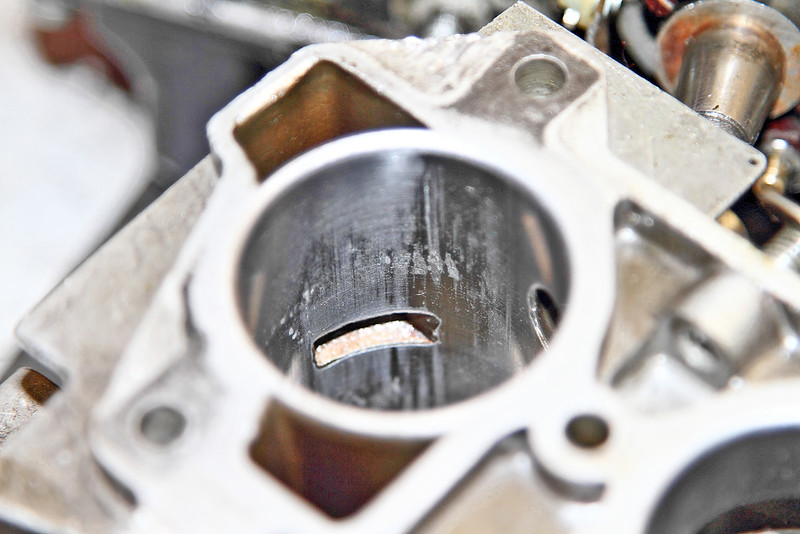

Here is the damaged cylinder as received. Remember...this is macro photography. While not pretty, it makes it look worse than it is. There is no transfer and no flaking NiSi.

Here is the damaged cylinder after a little light sanding by hand. It's not perfect, but it's entirely serviceable. As shown in the compression tests above, the cylinder is in good shape where it really counts...at the top of the bore. This topend dodged a bullet!

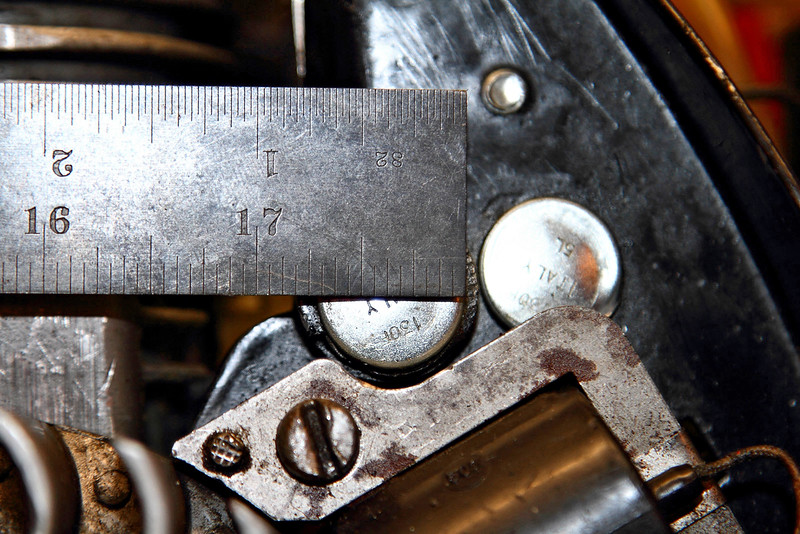

Here is the piston after some additional cleanup work. The skirt measures within .001" of the undamaged piston.

Here is the damaged cylinder after a little light sanding by hand. It's not perfect, but it's entirely serviceable. As shown in the compression tests above, the cylinder is in good shape where it really counts...at the top of the bore. This topend dodged a bullet!

Here is the piston after some additional cleanup work. The skirt measures within .001" of the undamaged piston.

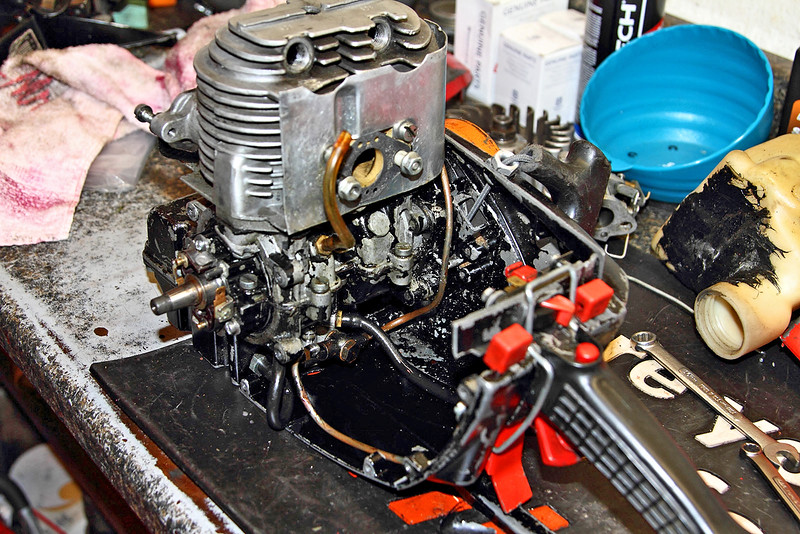

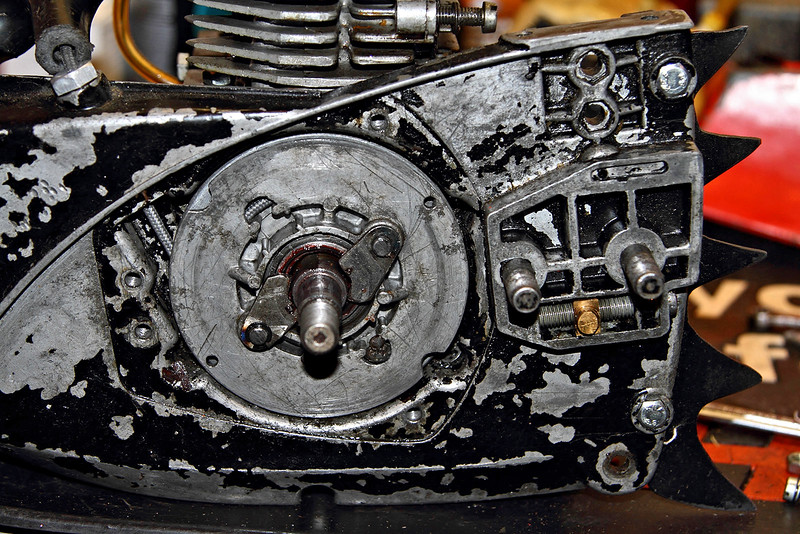

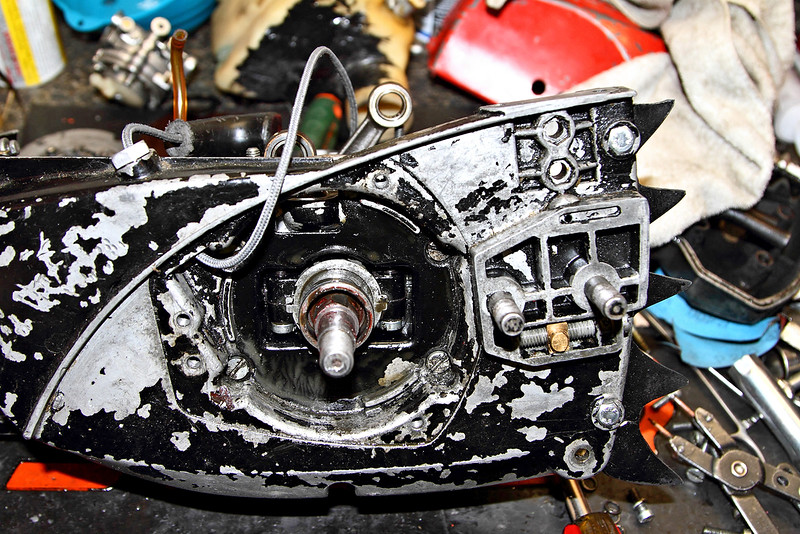

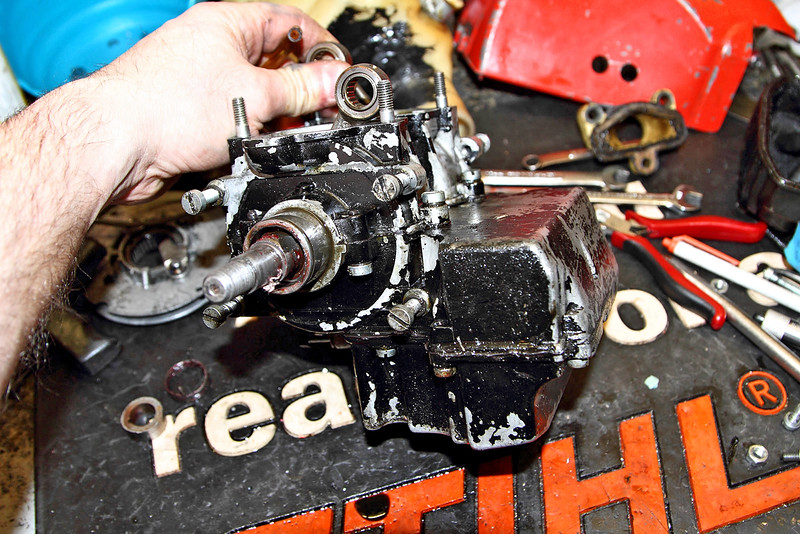

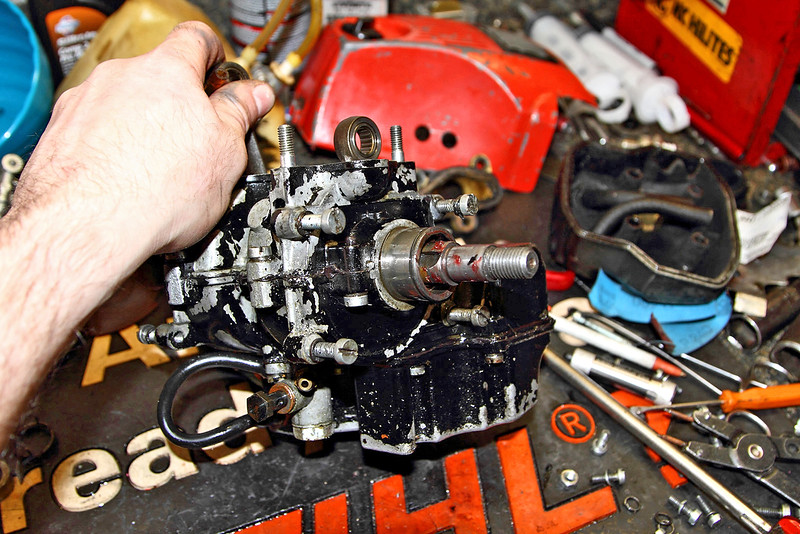

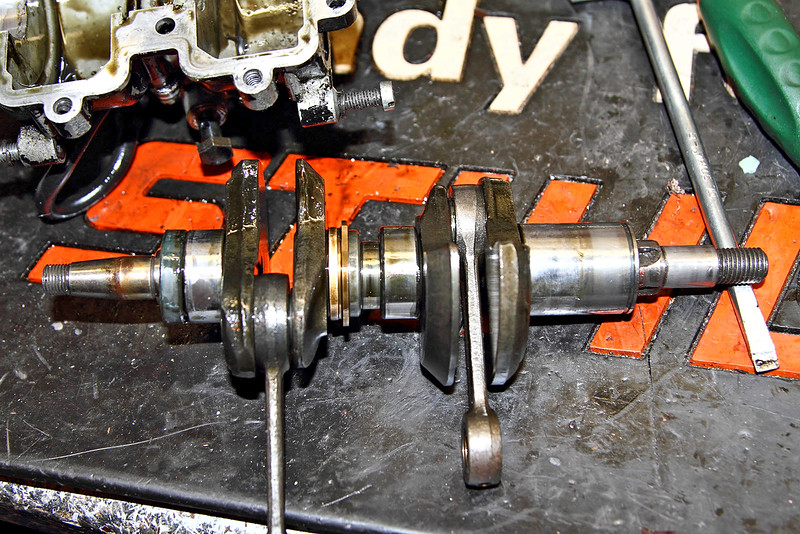

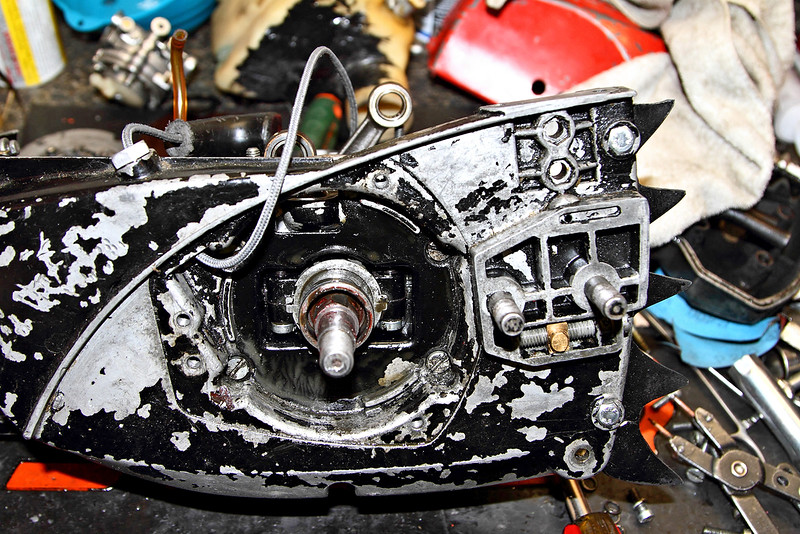

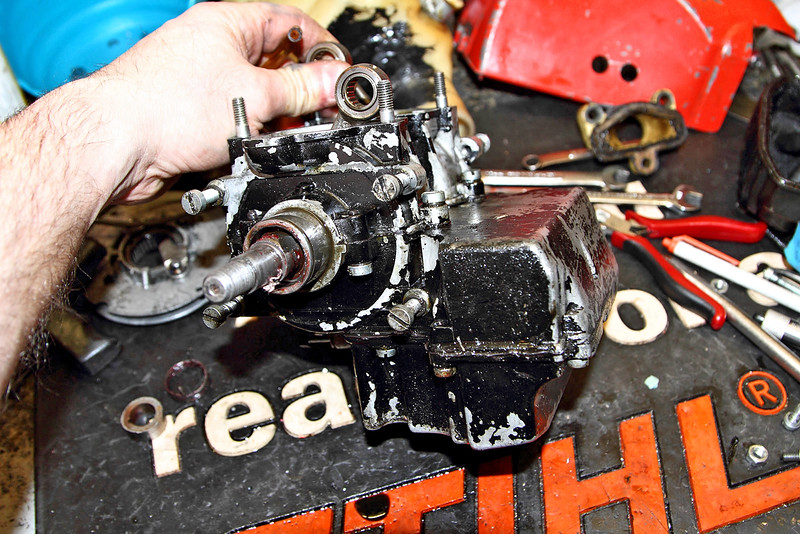

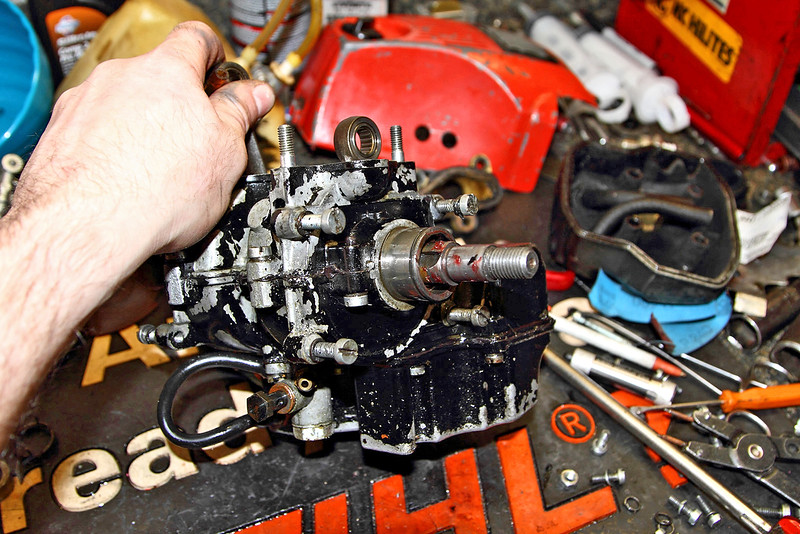

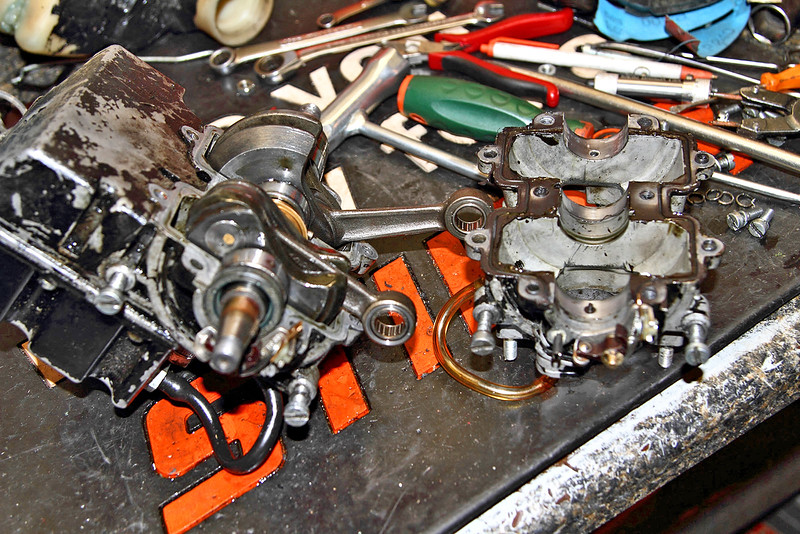

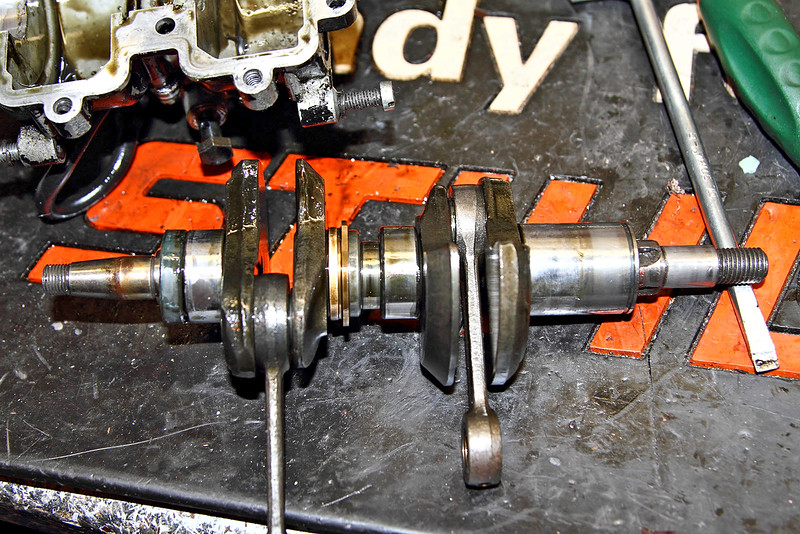

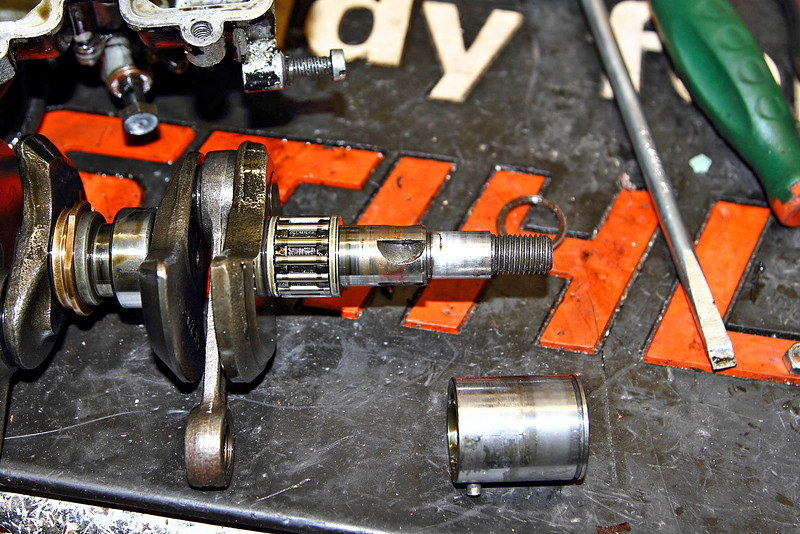

Continuing with the disassembly. These are the recoil pawls. They actually ride directly on the crankshaft.

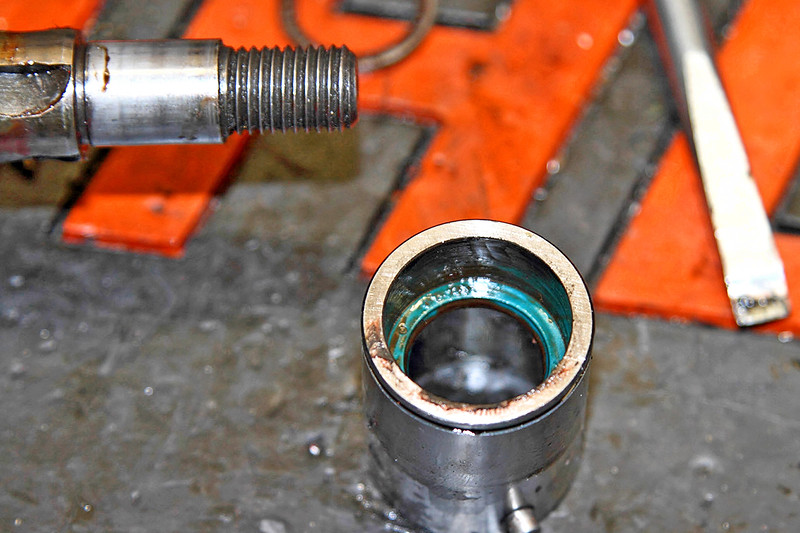

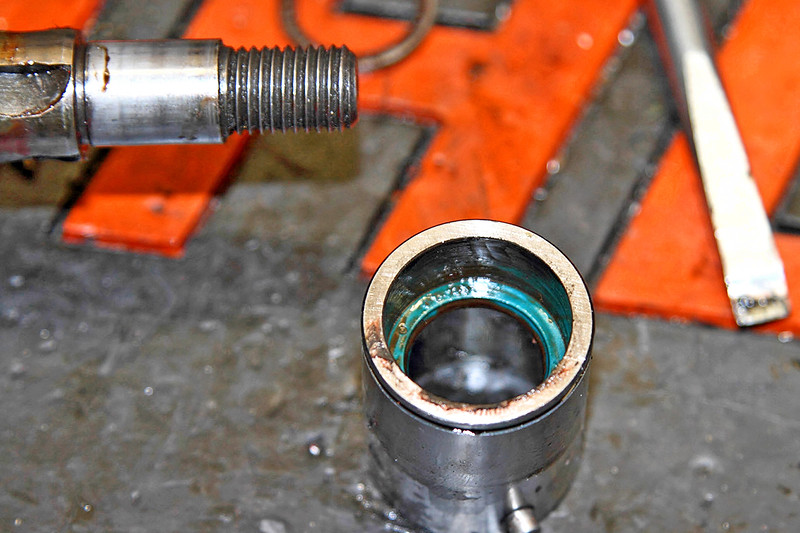

Not much left here! Where in the world is the crank seal?

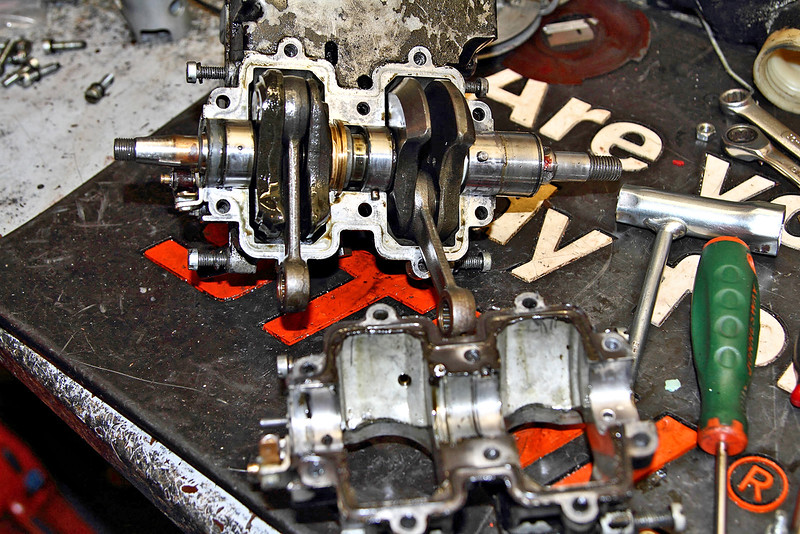

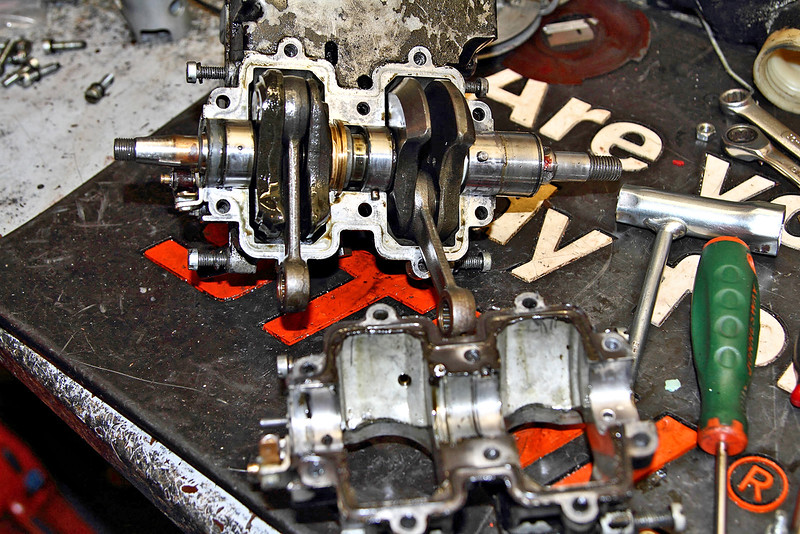

Nice beefy crank.

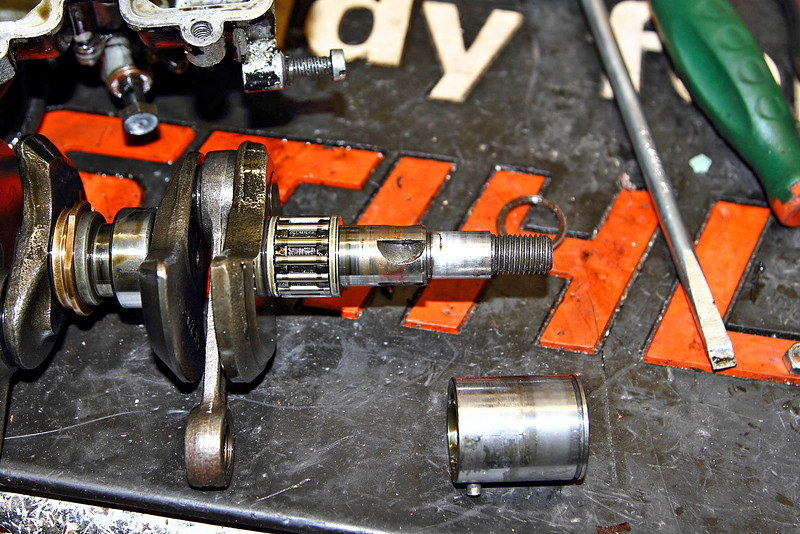

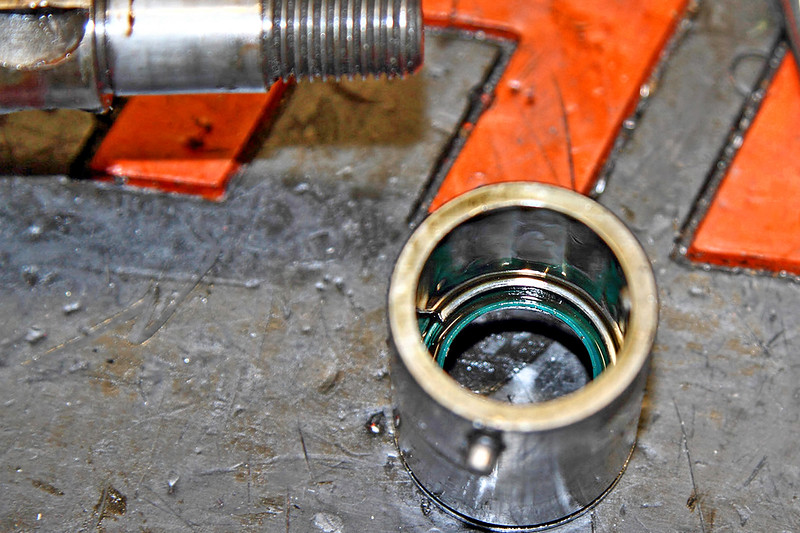

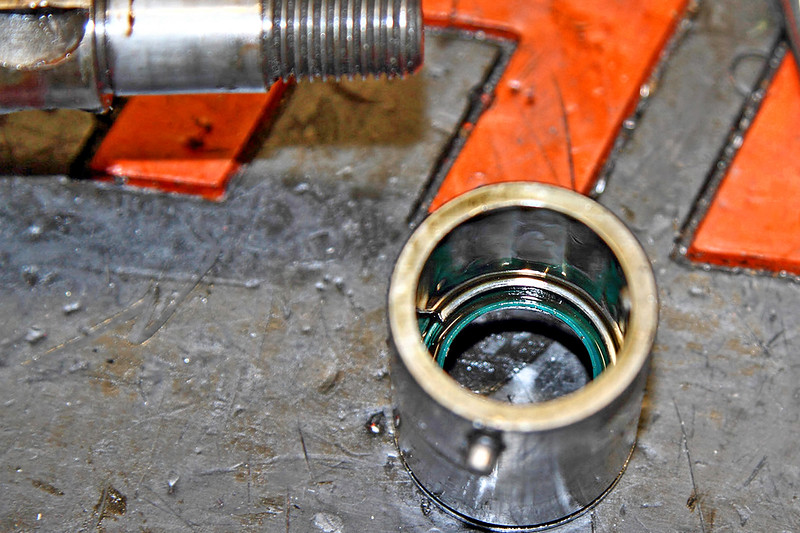

Where's that crank seal?

There it is! Lol.

18x24x3

Here's the flywheel side seal. 18x30x7

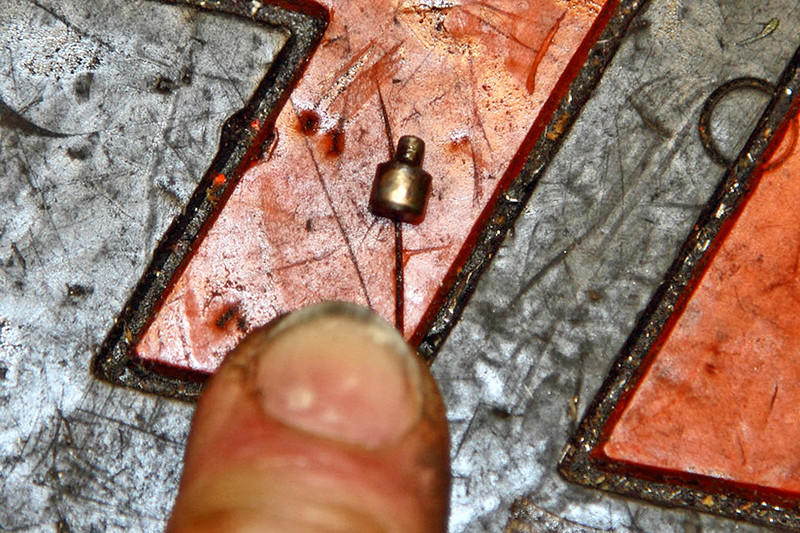

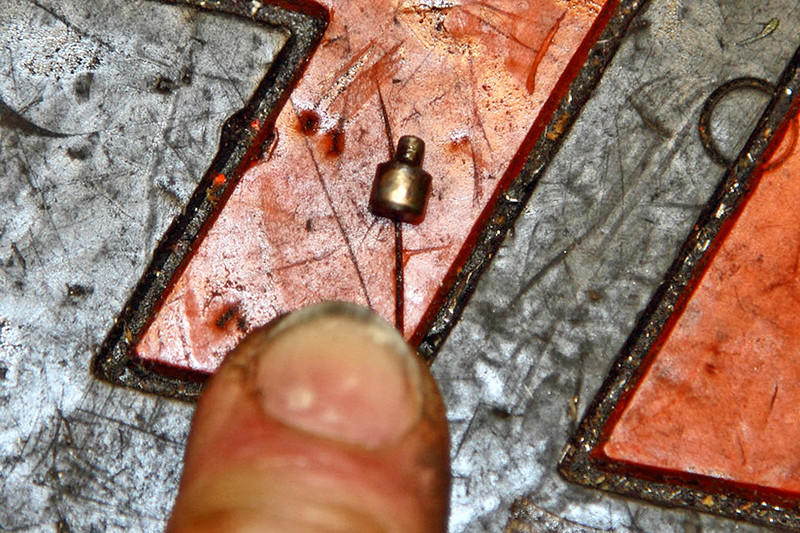

Don't loose these! There are three of these. The prevent the outer races from spinning in the crankcase.

Not much left here! Where in the world is the crank seal?

Nice beefy crank.

Where's that crank seal?

There it is! Lol.

18x24x3

Here's the flywheel side seal. 18x30x7

Don't loose these! There are three of these. The prevent the outer races from spinning in the crankcase.

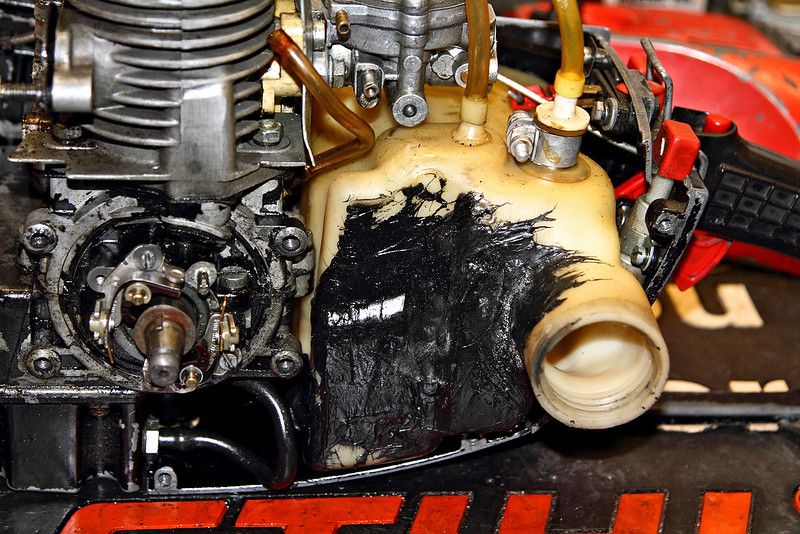

Here's the broken fuel tank, with all of the silicone removed. This was a known issues with this saw. I understand that it's a common problem with this model. It looks like someone previously tried to plastic weld it as well.

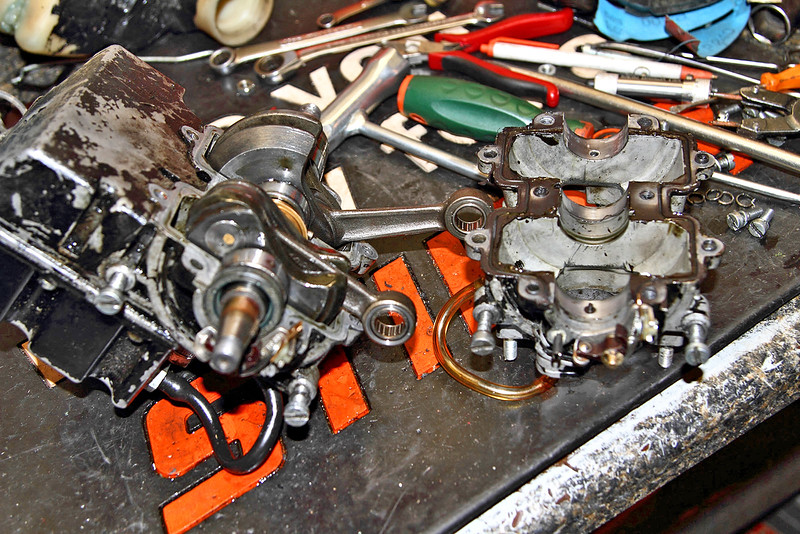

That's all of the pics for now. I decided to go ahead and split the crankcase in order to make sure that all seals are good and the saw will be reliable and trust worthy. I think I'm going to go ahead and powder coat it while it's apart. It only makes sense to do it now, even though I'm very anxious to get it back together and running.

While I'm certainly not happy about the P&C damage that I found, I am relieved that it is serviceable. Quite honestly, it will probably have no affect on either performance or reliability. Like I said earlier, you do what you have to do when working with old saws like this. After all, this saw is 50 years old!

While I'm certainly not happy about the P&C damage that I found, I am relieved that it is serviceable. Quite honestly, it will probably have no affect on either performance or reliability. Like I said earlier, you do what you have to do when working with old saws like this. After all, this saw is 50 years old!

On a good note, I found no damage to the crankcase. The crank itself is also in very good condition. All of the bearings are smooth and tight. The rings have very good end gap. Fortunately, I'm able to make the necessary repairs, and this Solo Twin will live to HOWL another day!

big t double

Addicted to ArboristSite

What's the plan with the fuel tank?

Similar threads

- Replies

- 23

- Views

- 3K

- Replies

- 22

- Views

- 3K