New Bar and Chain

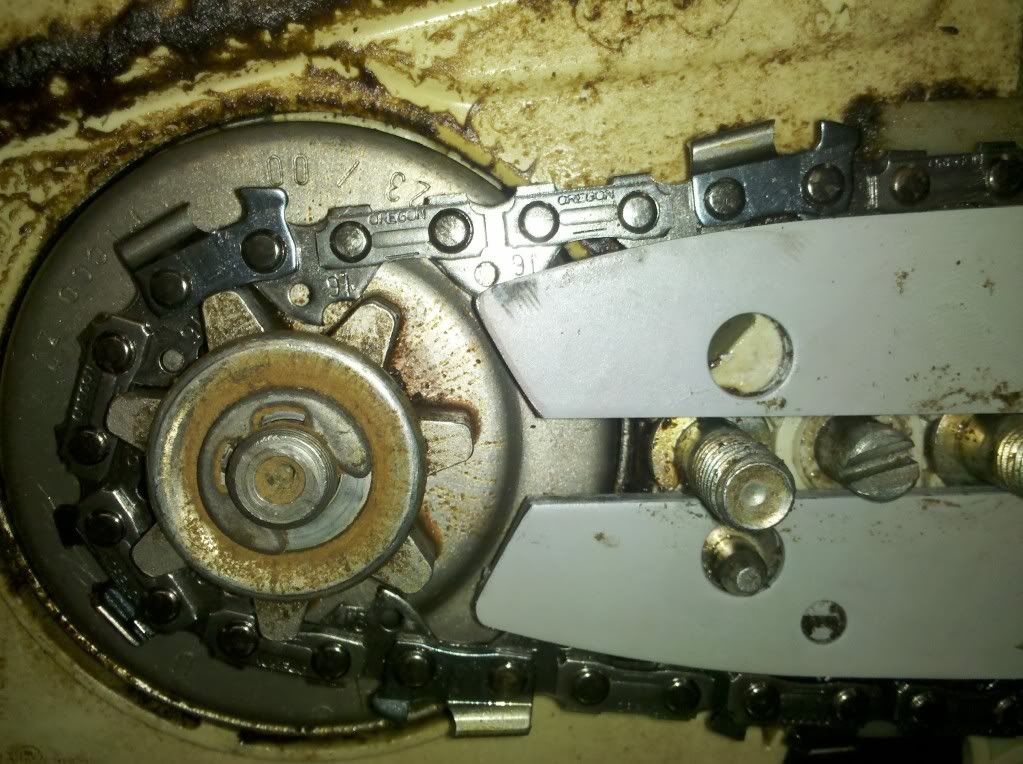

So I had this Oregon Pro 91 bar lying around and the new 91 vxl chain. Well the chain does run on the Picco bar but doesn't fit 100%. I've read some threads about the picco, 3/8 lo pro, vs reg. 3/8 chain. It seems the pitch is not the same. I still want to run the 3/8 lo pro on the picco sprocket. It looked like I had 3 drivers contacting so I made modifications to get a 56 link driver bar to work with a 55 link chain on the Stihl 025.

Difference in length. The Picco 55 driver length bar (16'') is on the bottom.

Difference at the rear of the bar when you align the adjuster hole up with the two bars.

Then here is the finished product as you can see how the ends were cut off the bar and the edges tapered to allow the chain to guide up the bar. Before the long tail of the pro 91 bar was touching the sprocket. Now this gives guys who want to run 3/8 lo pro without a safety bumper on the correct bar on our style saw!!!

I will be curious to see what type of life I get out of this.

-K5