I'll take some pics of the bars I use to do it tomarrow and post them. they dont have to be anything super special .

Nick unless your doing a new cly remember most of that plating is virgin material so you need to be real careful how far you shove that piston up in there:msp_ohmy:

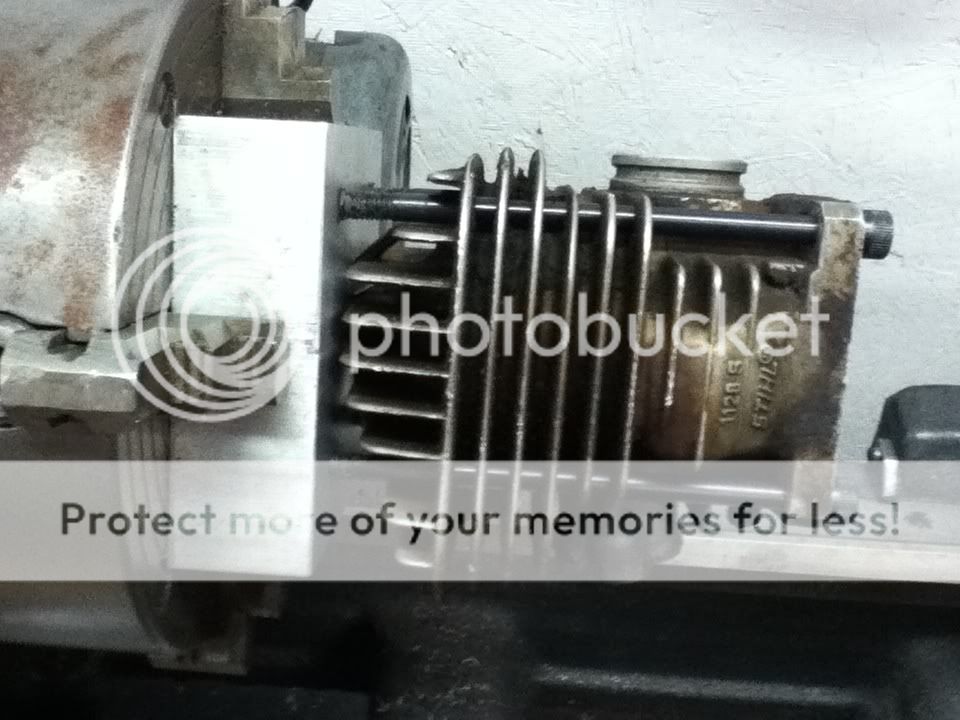

I have a cly to cut tomarrow I'll try to take some pics of how I do it.

Nick unless your doing a new cly remember most of that plating is virgin material so you need to be real careful how far you shove that piston up in there:msp_ohmy:

I have a cly to cut tomarrow I'll try to take some pics of how I do it.