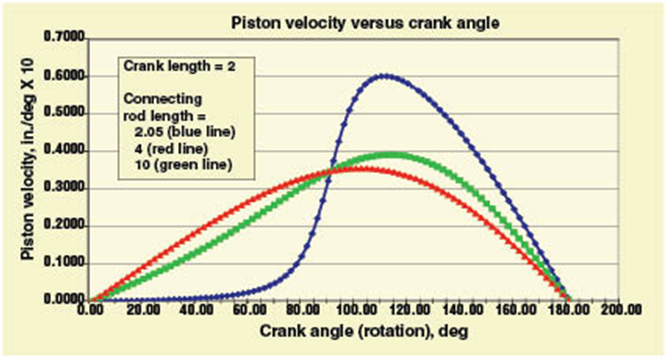

Yes it does. It represents position of the piston vs time. When you increase the rod length the wave changes, the piston spends more time near TDC and BDC for a given change in crank angle.

A longer rod ratio produces a more uniform piston velocity throughout its stroke. Thus a long rod produces lower peak piston velocities/accelerations/jerk etc. Generally, intake flow stagnates at sonic velocity. And since intake velocity through the ports is relatively proportional to piston speed, intake flow benefits from reduced peak piston velocity.

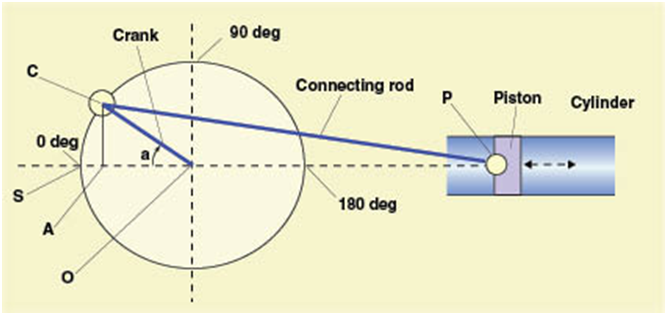

Engine design variables like stroke/bore ratios and rod ratios is an excercise in compromise. For low speed engines, a long rod is especially beneficial. It reduces peak piston velocities/accelerations and inertia loads on the rod and crank bearings. A long rod also minimises rod angulation and thrust load/friction losses at the piston skirt.