hank the tank

ArboristSite Lurker

- Joined

- Apr 7, 2014

- Messages

- 14

- Reaction score

- 2

Check your local pawn shops for saws and what not. I've bought most of my saws from one down the road from me. I got a 200t for $200 out the door, an ms361 for $225 in excellent condition and a 440 for $300. All of my other saws ran $100-$150.

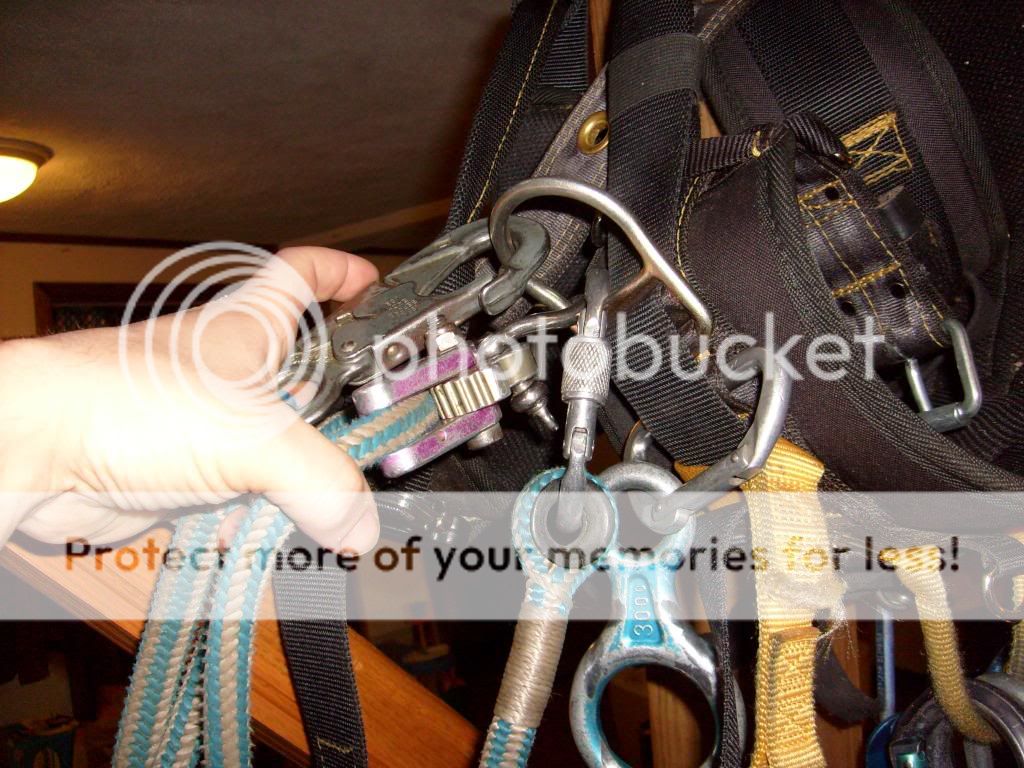

I wouldn't go buying used climbing gear or anything, but u can find some great deals on saws, especially if you get to know the ppl working there. They call me every time they get a stihl or husky.

I wouldn't go buying used climbing gear or anything, but u can find some great deals on saws, especially if you get to know the ppl working there. They call me every time they get a stihl or husky.