Good work. Now keep an eye on him if he’s going to be doing shady stuff with boxes

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Axe restoration thread

- Thread starter svk

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Shady stuff is probably a good term. I don’t think he’s down right dishonest. When he beat me out on the Kelly, it was in a wooden nail keg with a bunch of other stuff. He came over and offered me the keg and other stuff for free. We got to talking axes and last summer he bought a collection of 1200 axes for $10,000. He said he was still selling them. So, he’s in it to flip it. Now I know he has a limit if I really want something. If he can’t make money he’ll drop out. I might try and work a deal with him where I won’t bid at all on most axes so he can get them for $5, if he doesn’t drive up the occasional one I want.Good work. Now keep an eye on him if he’s going to be doing shady stuff with boxes

While I’m in the process of modifying this axe head into a Pickaroon is it OK for me to de-burr and clean up the “eye” of the axe head or should I leave it rough edged with an unfinished surface for a better grip on the handle?

Sent while firmly grasping my redline lubed RAM [emoji231]

Sent while firmly grasping my redline lubed RAM [emoji231]

I may have been a bit harsh in my description of him. People pull stuff form the back of the pile and put it back in the front, and vice versa. He didn't take it out of the box it was in and move it to another box. If I see someone pull something out of one box and put it in another, I'll politely ask them to put it back in the right box and point at it. If they don't, I know the auctioneer and I'll tell him. Then he makes a joke of it and says stuff like, this thing must be hot, it keeps jumping from box to box, lets sell it separate. When I pointed the guy out to my cousin he told me about a small hump backed trunk he bought. He collected hump back trunks so he wanted it. It was also full of doll clothes, so, he decided he's go extra on it so he could give the clothes to his Grand Daughter. When the bidding started some guy started running it up way past what it was worth, but he kept bidding and got it. When he got home and pulled the doll clothes out, there was a sterling silver beaded purse on the bottom that wasn't there when he first looked. That's the kind of stuff that bugs me. If I see a box with something I like early, I make sure my item didn't get hot and jump to another box.Personally i wouldn't have any connection with him at all.

You'd be giving the shadiest person, preferential treatment.

I'd keep doing my thing.

Multifaceted

Firewood Hoarder, Axe Enthusiast

While I’m in the process of modifying this axe head into a Pickaroon is it OK for me to de-burr and clean up the “eye” of the axe head or should I leave it rough edged with an unfinished surface for a better grip on the handle?

Sent while firmly grasping my redline lubed RAM [emoji231]

Definitely de-burr, on both top and bottom, itis also good practice for any re-hanging of a regular axe. Any restoration I do, I take a half-round and rat tail file to the eye to smooth it out, makes for easier fitting and removal, plus mitigates the amount of severe curling of the wood.

Definitely de-burr, on both top and bottom, itis also good practice for any re-hanging of a regular axe. Any restoration I do, I take a half-round and rat tail file to the eye to smooth it out, makes for easier fitting and removal, plus mitigates the amount of severe curling of the wood.

Thank you sir.[emoji1303]

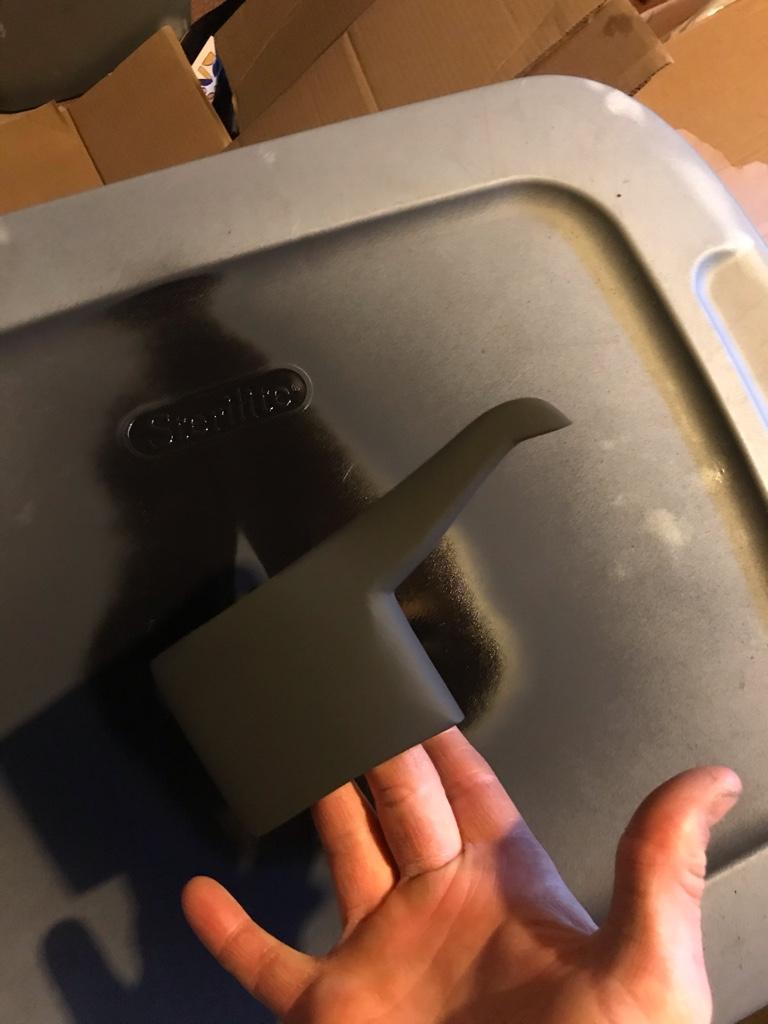

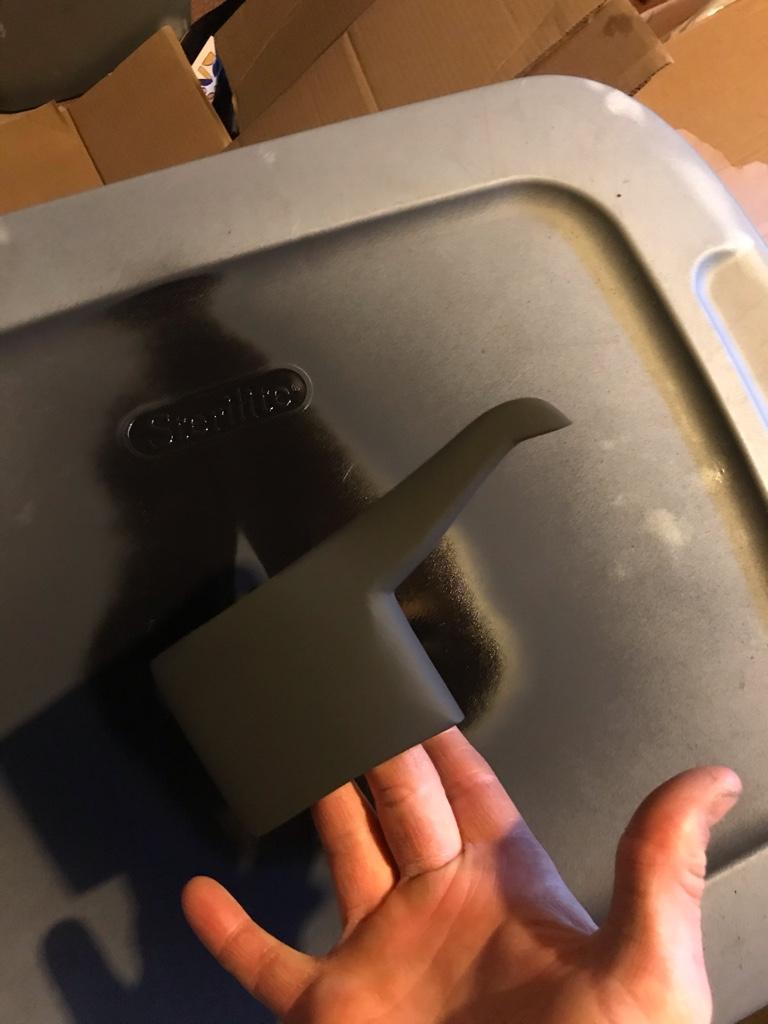

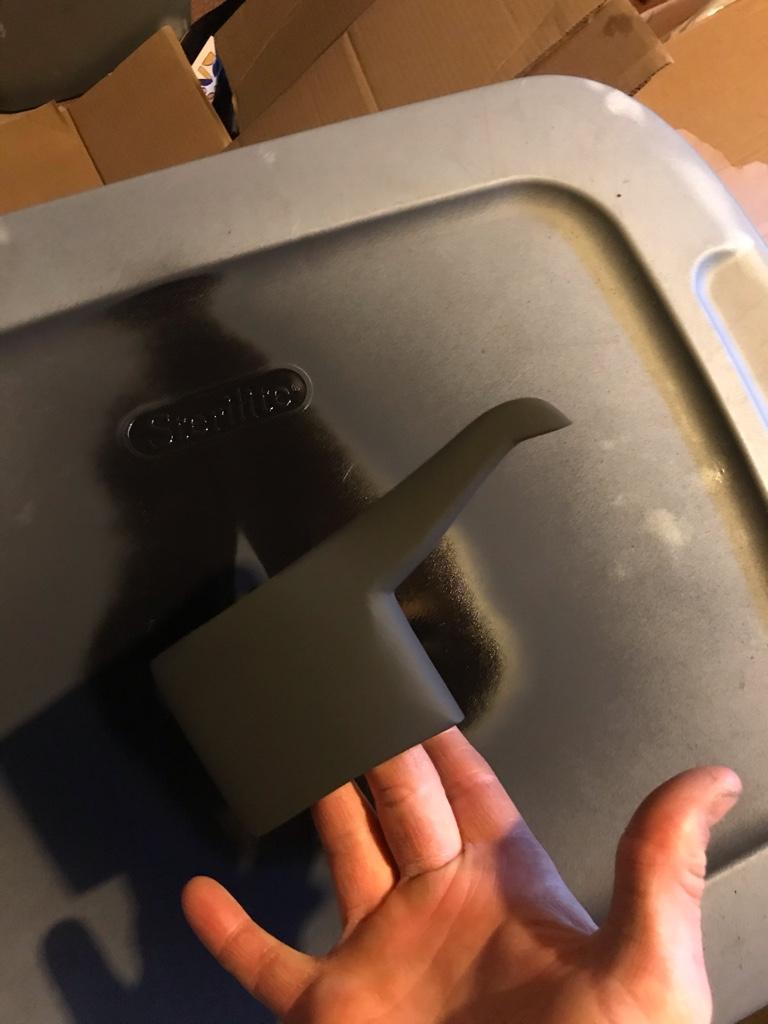

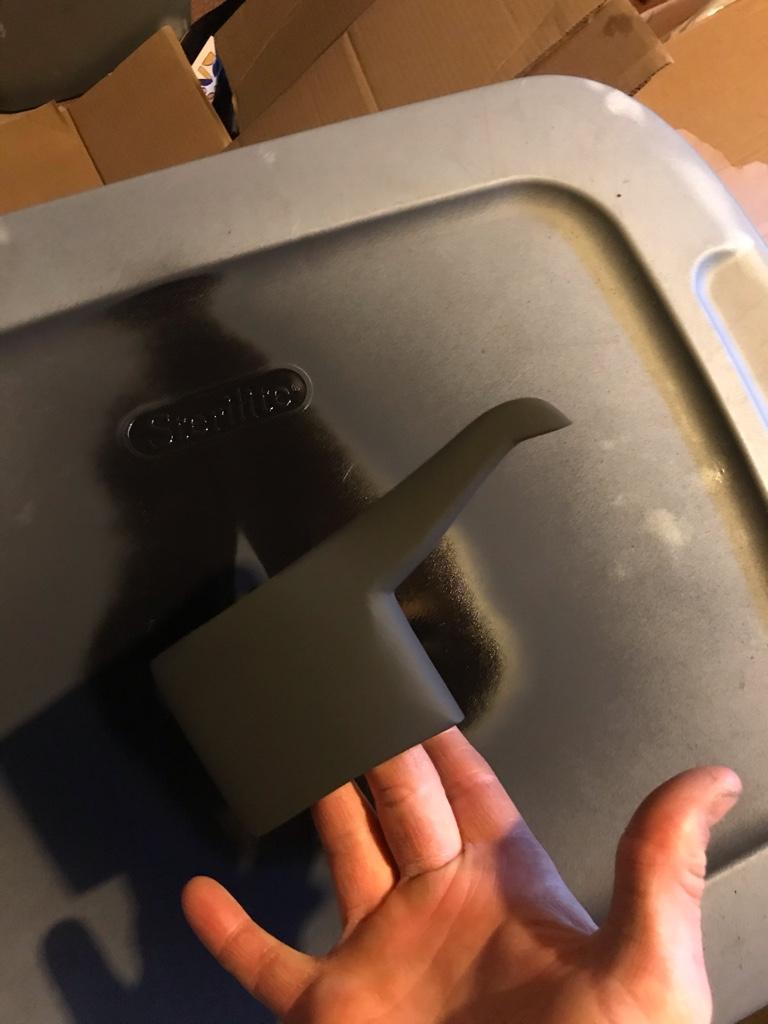

I used a carbide burr bit and then sand blasted the rust out of the inside of the eye.

Original plan was to keep her polished but in reality this things going to be sitting out by the woodpile and or bouncing around in the back of my truck. So I painted it just now.

Planning on looking for a handle this weekend. Thinking I should go with something around 20” or so. Hoping this works good for sticking in the end of rounds to pick them up and move them around.

May have to modify the point on it after i see how it works.

Sent while firmly grasping my redline lubed RAM [emoji231]

Multifaceted

Firewood Hoarder, Axe Enthusiast

Thank you sir.[emoji1303]

I used a carbide burr bit and then sand blasted the rust out of the inside of the eye.

Original plan was to keep her polished but in reality this things going to be sitting out by the woodpile and or bouncing around in the back of my truck. So I painted it just now.

Planning on looking for a handle this weekend. Thinking I should go with something around 20” or so. Hoping this works good for sticking in the end of rounds to pick them up and move them around.

May have to modify the point on it after i see how it works.

Sent while firmly grasping my redline lubed RAM [emoji231]

All a good call. Might not even be a bad idea to throw a coat of lacquer on there to protect the paint from chipping off. As far as length, perhaps do some trials. I'm kind of tall so 20" seems like I'd be bending down trying to stick the barb into the end grain of a log or split. My pickaroon is 30" long, but I use it mostly for grabbing logs from atop the log pile and putting them into position to strike with my splitting axe, or pick up splits from the ground and toss them into a cart or pile. All depends on how you plan use it.

All a good call. Might not even be a bad idea to throw a coat of lacquer on there to protect the paint from chipping off. As far as length, perhaps do some trials. I'm kind of tall so 20" seems like I'd be bending down trying to stick the barb into the end grain of a log or split. My pickaroon is 30" long, but I use it mostly for grabbing logs from atop the log pile and putting them into position to strike with my splitting axe, or pick up splits from the ground and toss them into a cart or pile. All depends on how you plan use it.

Im 5’8” 175lbs.

Definitely not tall[emoji23]

Sent while firmly grasping my redline lubed RAM [emoji231]

Multifaceted

Firewood Hoarder, Axe Enthusiast

Im 5’8” 175lbs.

Definitely not tall[emoji23]

Sent while firmly grasping my redline lubed RAM [emoji231]

Height is just a number, I'm thinking more of your back. Maybe get a couple lengths of stick and swing them so that they skirt the ground by about 2-3" on swing. That should be a good length I would think. I see a lot of the shorter handled pickaroons for guys who run hydro-splitters. If I'm not mistaken, you split by hand, correct?

That looks very nice.Thank you sir.[emoji1303]

I used a carbide burr bit and then sand blasted the rust out of the inside of the eye.

Original plan was to keep her polished but in reality this things going to be sitting out by the woodpile and or bouncing around in the back of my truck. So I painted it just now.

Planning on looking for a handle this weekend. Thinking I should go with something around 20” or so. Hoping this works good for sticking in the end of rounds to pick them up and move them around.

May have to modify the point on it after i see how it works.

Sent while firmly grasping my redline lubed RAM [emoji231]

That looks very nice.

Thanks. I hope it works nice[emoji1787]

Sent while firmly grasping my redline lubed RAM [emoji231]

I’d recommend 28-32” myself. Longer reach but not too long.Thank you sir.[emoji1303]

I used a carbide burr bit and then sand blasted the rust out of the inside of the eye.

Original plan was to keep her polished but in reality this things going to be sitting out by the woodpile and or bouncing around in the back of my truck. So I painted it just now.

Planning on looking for a handle this weekend. Thinking I should go with something around 20” or so. Hoping this works good for sticking in the end of rounds to pick them up and move them around.

May have to modify the point on it after i see how it works.

Sent while firmly grasping my redline lubed RAM [emoji231]

MechanicMatt

Cut Split Stack Burn

that one hatchet has some beautiful lines to it. Looks like a tomahawk

Okay, I stuck with the best handle I could find. I didn't make the rarefish wedge. I decided to fill the cavity with 4400# epoxy instead. No epoxy on the wedge; oriented the metal wedge pretty much opposite of the grain which unintentionally resulted in little of it in the handle - I am guessing I should have gone 90* to the grain. Cut the handle down to just over 30", initialed it, burned some grooves for a grip on the end and oiled with one coat of boiled linseed oil. Maybe a Saturday or two before I will get to pound some wedges with it.

Ron

Ron

Height is just a number, I'm thinking more of your back. Maybe get a couple lengths of stick and swing them so that they skirt the ground by about 2-3" on swing. That should be a good length I would think. I see a lot of the shorter handled pickaroons for guys who run hydro-splitters. If I'm not mistaken, you split by hand, correct?

Yes sir. The 36” fiskars

I will take the advice everyone and go longer. My local stores are not heavily stocked so ill most likely end up buying a 36”(seems common around here) and cut it down a bit.

Sent while firmly grasping my redline lubed RAM [emoji231]

Okay, I stuck with the best handle I could find. I didn't make the rarefish wedge. I decided to fill the cavity with 4400# epoxy instead. No epoxy on the wedge; oriented the metal wedge pretty much opposite of the grain which unintentionally resulted in little of it in the handle - I am guessing I should have gone 90* to the grain. Cut the handle down to just over 30", initialed it, burned some grooves for a grip on the end and oiled with one coat of boiled linseed oil. Maybe a Saturday or two before I will get to pound some wedges with it.

View attachment 799508 View attachment 799509

View attachment 799510

Ron

I like the axe head. A 3lb’er...?

Not so sure about the burned grooves but to each his own right...[emoji1303][emoji41]

Sent while firmly grasping my redline lubed RAM [emoji231]

I passed up one last month at the same auction, it was in the last building, and they don't start that building till about 7PM. It was 4 and I didn't feel like waiting. It was the next size bigger, but still a small hatchet. They are still available at LL Bean for about $150. I've been talking about finding a small hatchet to use for field dressing my deer, this will fit the bill. Has good steel that will hold an edge. The profile of the edge will be good for skinning, and I can crack the pelvis in the field to get the poop chute out. I just did a search for LL bean and they have a Gransfor, so maybe it's not still available new. Back to the search function.that one hatchet has some beautiful lines to it. Looks like a tomahawk

I didn't notice the epoxy till you mentioned it. Looks good.Okay, I stuck with the best handle I could find. I didn't make the rarefish wedge. I decided to fill the cavity with 4400# epoxy instead. No epoxy on the wedge; oriented the metal wedge pretty much opposite of the grain which unintentionally resulted in little of it in the handle - I am guessing I should have gone 90* to the grain. Cut the handle down to just over 30", initialed it, burned some grooves for a grip on the end and oiled with one coat of boiled linseed oil. Maybe a Saturday or two before I will get to pound some wedges with it.

View attachment 799508 View attachment 799509

View attachment 799510

Ron

Multifaceted

Firewood Hoarder, Axe Enthusiast

Okay, I stuck with the best handle I could find. I didn't make the rarefish wedge. I decided to fill the cavity with 4400# epoxy instead. No epoxy on the wedge; oriented the metal wedge pretty much opposite of the grain which unintentionally resulted in little of it in the handle - I am guessing I should have gone 90* to the grain. Cut the handle down to just over 30", initialed it, burned some grooves for a grip on the end and oiled with one coat of boiled linseed oil. Maybe a Saturday or two before I will get to pound some wedges with it.

View attachment 799508 View attachment 799509

View attachment 799510

Ron

I've been hunting for a good heavy rafting pattern with hardened poll for a long time now. Can find on eBay for an exorbitant price, but nah...

Similar threads

-

- Sticky

- Replies

- 0

- Views

- 2K