U&A

Addicted to ArboristSite

Nothing but mud over here... lol

Somehow there is copious amounts of mud underneath the snow here [emoji23]

Sent while firmly grasping my redline lubed RAM [emoji231]

Nothing but mud over here... lol

Tell me what you think. I’m here to learn and I have thick skin[emoji16][emoji1303][emoji41]

Sent while firmly grasping my redline lubed RAM [emoji231]

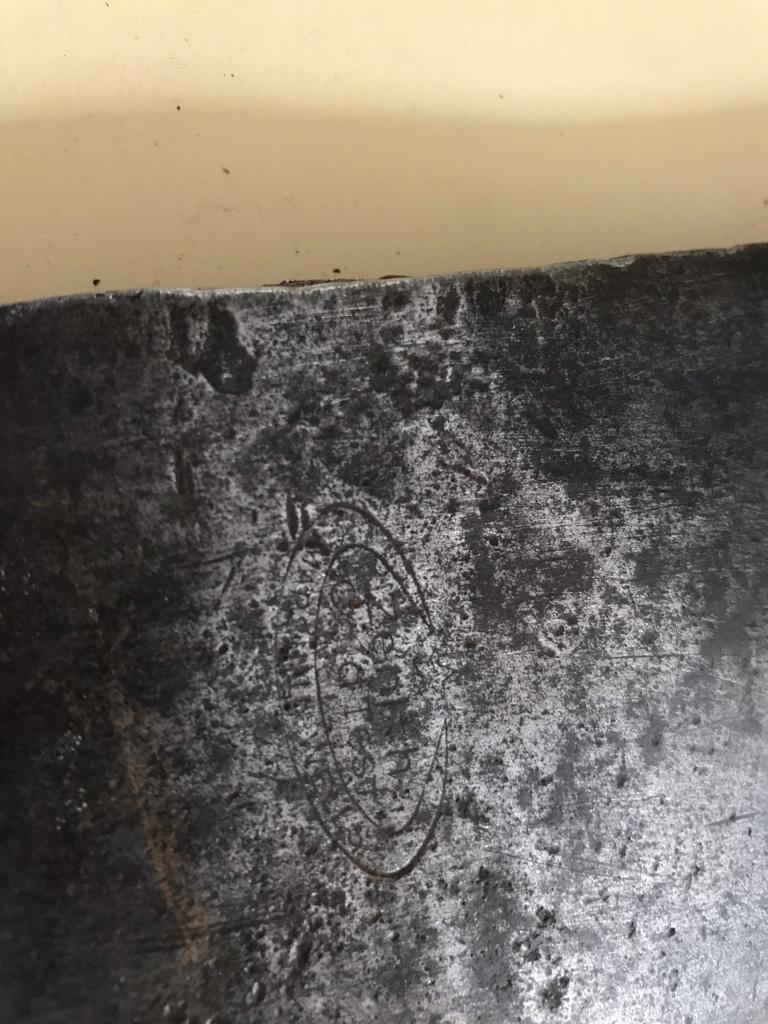

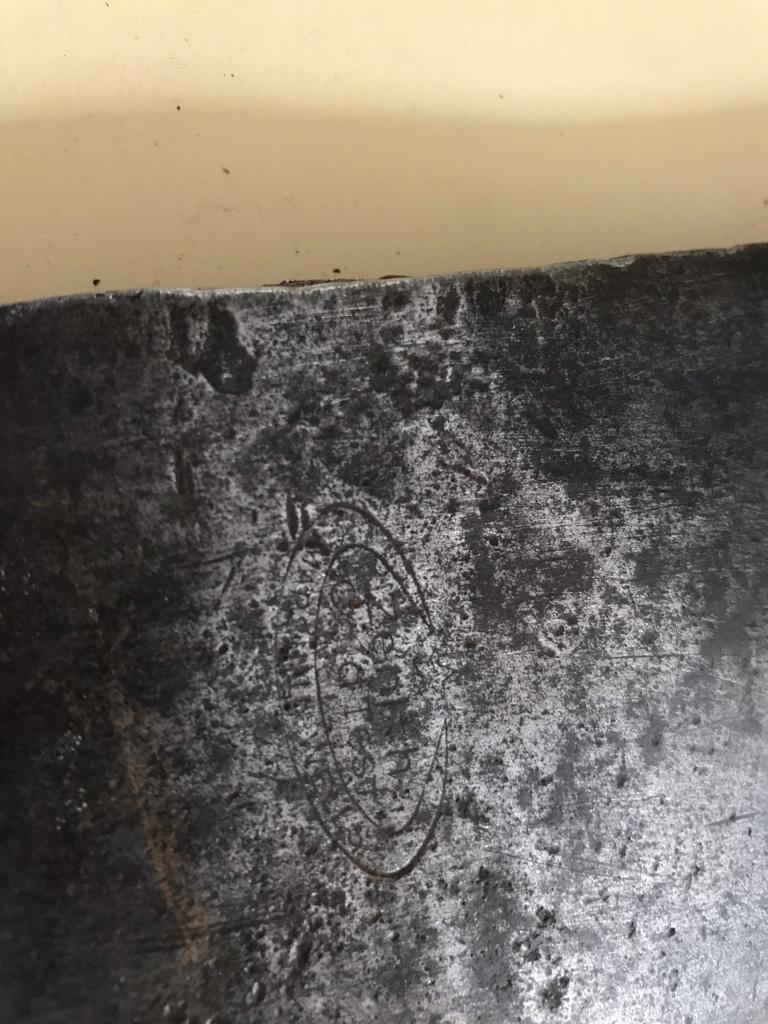

Did you try “yesteryeartools”, they have a pretty good write up on Kelly over the years. I didn’t notice any logo that looked like yours?Reaching out to my buds to see if you can help identify this a little more specifically than just saying it’s a Zenith Marshall Wells.

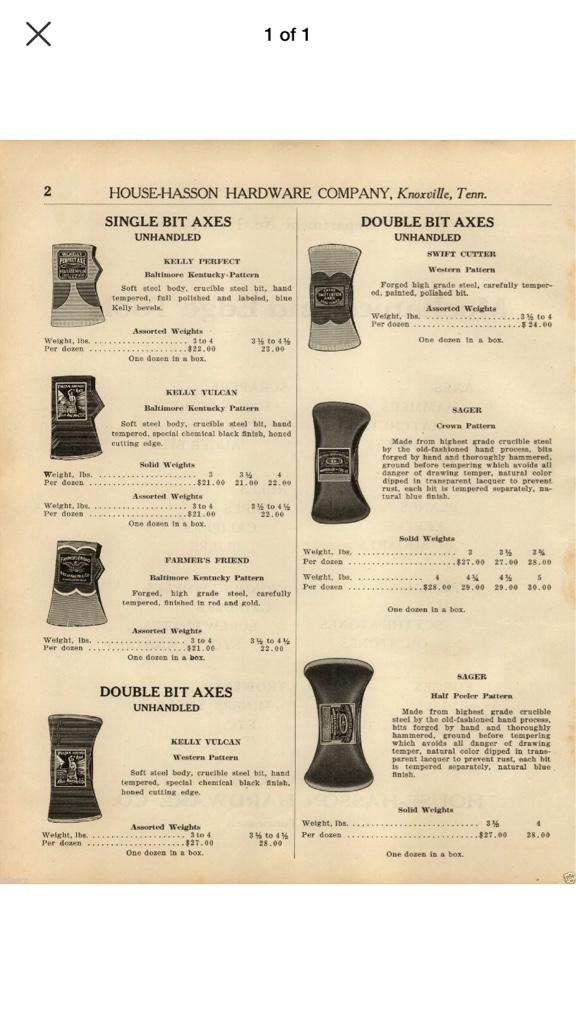

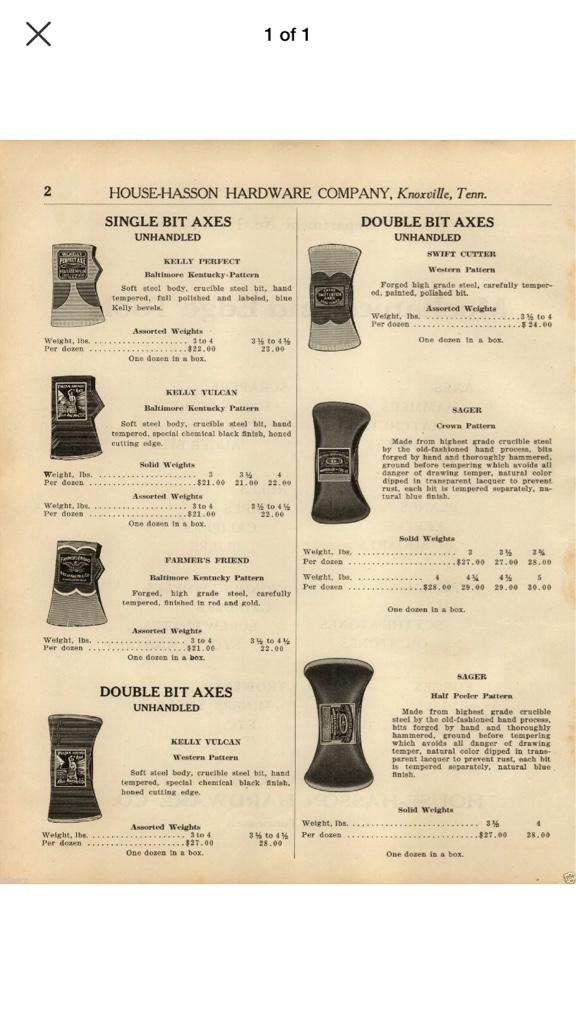

Based on this image showing the different types they had I am guessing my ex would be the one in the top right corner or the bottom left. But I’m not 100% sure

Can anyone give me further insight?

The shape of the outside contour of this looks like the “Sager” but the edges look different

I was told this was probably made by Kelly...

Sent while firmly grasping my redline lubed RAM [emoji231]

You gonna be making these axes real and proper choppers, or just relegating them to splitting logs?

Not splitters. I have a Fiskars for that and its hard to beat.

Choppers they will be! Definitely want to keep at least one of them possibly will sell the other. .... if someone actually wants it.

Sent while firmly grasping my redline lubed RAM [emoji231]

Dont forget the makin beer part....[emoji16]Good to hear! f you ever need some guidance or pointers on getting a right and proper proper grind geometry that will sever fibers and clear chips, feel free to message me. I've been known to do some chopping here and there.

Well boys, in the bed of my truck is my Grandpa’s Ax, I had intentions of taking a picture tonight but my 15yo needed help with her homework. Tomorrow I’ll be sure to get a picture

Good to hear! f you ever need some guidance or pointers on getting a right and proper proper grind geometry that will sever fibers and clear chips, feel free to message me. I've been known to do some chopping here and there.

Pm inbound

Sent while firmly grasping my redline lubed RAM [emoji231]

Those are nice.Got the Marshall wells and True Temper cleaned up with red scotch bright today.

Marshall Wells is in decent shape besides the minor pitting. The TT has met a grinder once or twice. Somebody did a number in it but after cleaning it up it really is not too bad. Will make a great tool but it’s not going to win any beauty contest.

Sent while firmly grasping my redline lubed RAM [emoji231]

Those are nice.

Does anyone know: Is there any difference in performance in the bowtie shape versus the rounded edge shape?

Those are nice.

Does anyone know: Is there any difference in performance in the bowtie shape versus the rounded edge shape?

Rounded edge is likely exaggerated due to years of improper grinding. The toe of the bit is the part often subject to the most wear and damage this often gets more of the file. Without trueing up the bit before major damage repair, you get the rounded bit. Also, as is often the case with American axes that have cheeks, the heel and toe are much thinner than the center of the bit with the cheeks flare out, there's also much more steel there which translates into more material that needs to be removed in order to do a proper cutting grind. Most people just follow the existing contour and file the edge to a point, then call it day, and that is not the best way. It's not even a good way, middling perhaps.

Enter your email address to join: