Colonel428

ArboristSite Operative

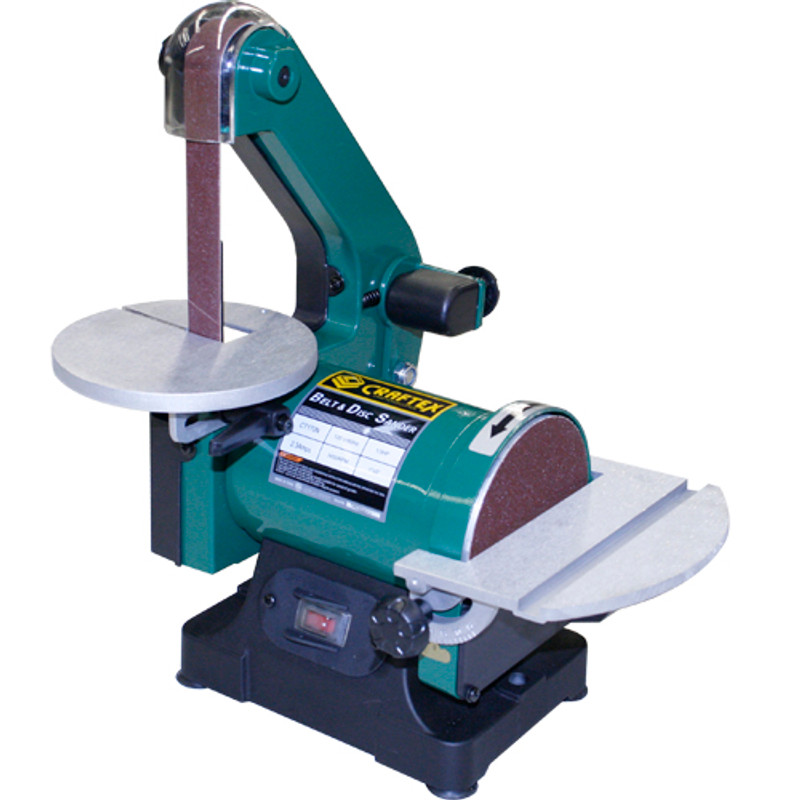

Who uses one of these to be able to give real world feedback? I've just been using a flat file to take off any lip that forms on the edges of my bars. Wondering if a dedicated bar dressing tool is that much better. Thanks.