Buckethead

ArboristSite Operative

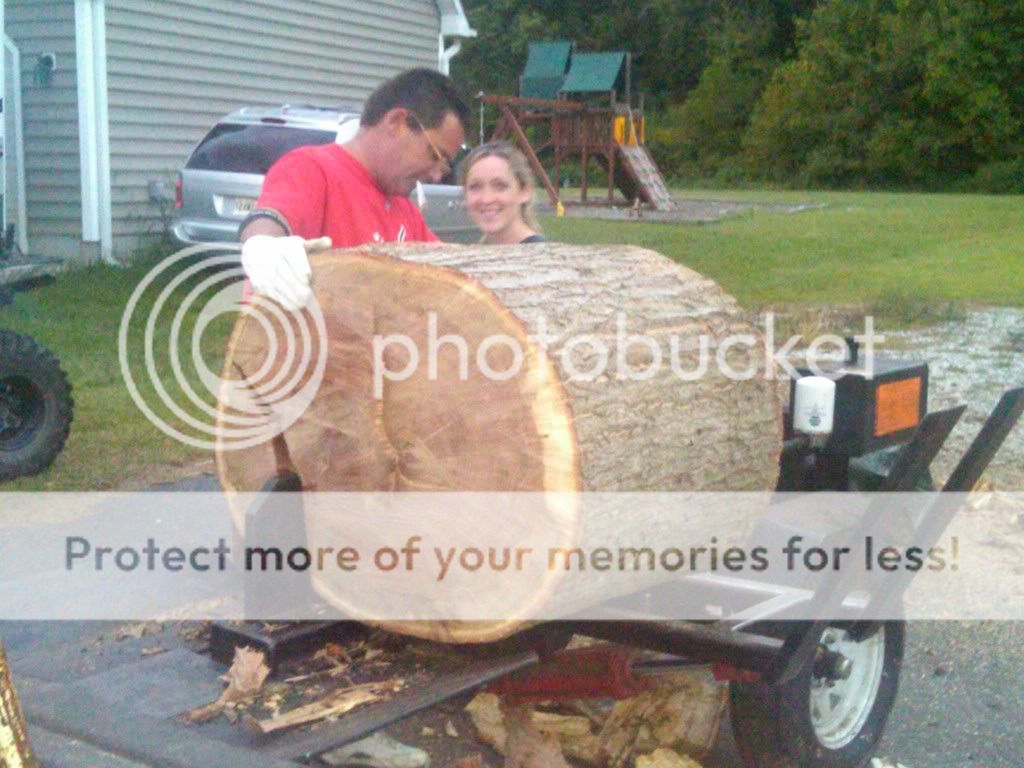

This isn't the biggest but it was a pretty big one.

I've also noticed that a lot of these "big round" pictures also include a Timberwolf splitter...just sayin' is all.....

I've also noticed that a lot of these "big round" pictures also include a Timberwolf splitter...just sayin' is all.....