nmurph

ArboristSite.com Sponsor

- Joined

- Nov 26, 2007

- Messages

- 16,162

- Reaction score

- 7,166

This is what I did to mine when the swivel tip broke off. It is an 11mm bearing welded on.

No picture here Neil but I know it works good as I have done similar on several homemade pullers.This is what I did to mine when the swivel tip broke off. It is an 11mm bearing welded on.

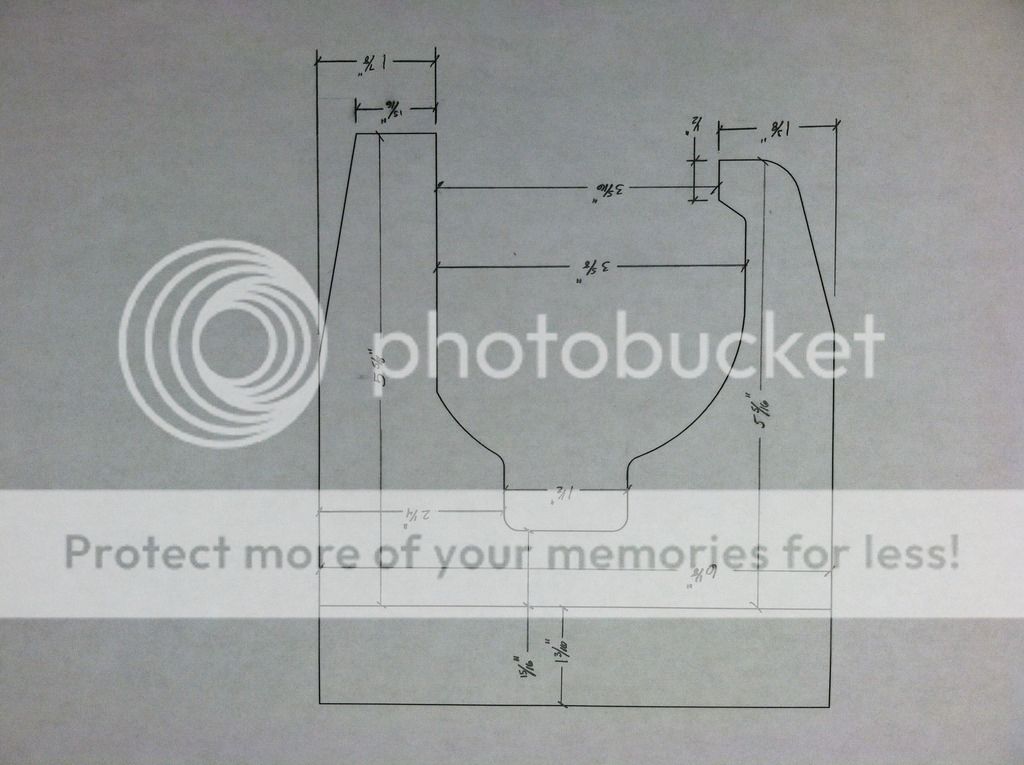

Thanks for posting this. Another member mailed me a template but I cant recall where I placed it. I started looking and found this PDF. Great stuff! IDK if I printed it the right size... If someone gives me some better dimensions I will add them to this template and repost it. That way in the future someone can print this to scale and verify the print scale is accurate... let me know.See attached.

Print 1:1 or 100%

The tubing is basically 1.5" x 1" x .125 wall rectangular tubing, but it must be a metric size, because it measures slightly over that (1.5" square tubing would be fine)......the flat plates that make the fork are .25" plate and the fork measures 1.125" inside and 1.625 outside.

The dimension in the fourth pic is important.

Im having trouble visualizing the measurements you are describing here because the math isnt adding up to me... Can you possibly post a picture to help? A 0.25" flat plate welded flush with the 1.25" sides of the rectangular tube should make the forks 1.5" outside and 1" inside the plates... Maybe the plates are something other than 0.25"? Can someone confirm?

great work Marshy!View attachment 420917

View attachment 420916

Finished product right there boys. Last thing is some paint. Stay tuned lol.

You are correct. The stock used for the backbone in mine was 1.125" thick so the plates overlapped the stock to get the 1.125" distance inside of the forks. Lots of ways to skin this cat.Am I missing something here but if your plates are welded on the outside of the "backbone" plate, the distance between the plates will be whatever the thickness of the backbone plate is. Just wondering, I'm fixing to fab one of these and am just getting all my ducks in a row.

A 266 SE or 162SE. They are within a couple thousands of an inch of each other.what saw are you measuring there?

I usually start with a bfh-8 and adjust accordingly.You have the bfh-12 ?

Enter your email address to join: