i use a dremel with a thin cut disk,, i don't even take the mixture screws out,, i just cut the slot which also cuts into the carb housing but that doesn't hurt a thing

well, hell...didn't think of that

i use a dremel with a thin cut disk,, i don't even take the mixture screws out,, i just cut the slot which also cuts into the carb housing but that doesn't hurt a thing

i use a dremel with a thin cut disk,, i don't even take the mixture screws out,, i just cut the slot which also cuts into the carb housing but that doesn't hurt a thing

well, hell...didn't think of that

After

[video=youtube_share;dp7kmMJAE5g]http://youtu.be/dp7kmMJAE5g[/video]

Good running 38cc! Red Oak?

Serves you right showoff.... Excellent job, I'd like to do one of mine like that if I could weld that thin metal.

.png)

Me, too. I can't weld that thin stuff so I have to go with the old heat and bend method. It's slower but it works and doesn't look too bad when I finish. The muffler mod is a MUST on these. The muffler is incredibly restrictive, which may be why we're getting them. Maybe this batch didn't meet emission standards and they had to dump them on the market. Combine those with some customer returns, call them "Sold as is, for parts" and you've got the makings of an internet / CAD love story.

I checked compression and squish on mine, which as most of you know has been ported, muff modded and base gasket removed. The compression was around 150 out of the box and now sets at a respectable 162 psi cold. There is much to be gained, however, 'cause squish is .039 with no base gasket.

I'm glad I didn't raise or lower the ports on this one. Now I just have to find a pop up piston or get the cylinder machined...:msp_sneaky:

Forgive my ignoreance, but what is squish and what is a pop up piston?

Me, too. I can't weld that thin stuff so I have to go with the old heat and bend method. It's slower but it works and doesn't look too bad when I finish. The muffler mod is a MUST on these. The muffler is incredibly restrictive, which may be why we're getting them. Maybe this batch didn't meet emission standards and they had to dump them on the market. Combine those with some customer returns, call them "Sold as is, for parts" and you've got the makings of an internet / CAD love story.

I checked compression and squish on mine, which as most of you know has been ported, muff modded and base gasket removed. The compression was around 150 out of the box and now sets at a respectable 162 psi cold. There is much to be gained, however, 'cause squish is .039 with no base gasket.

I'm glad I didn't raise or lower the ports on this one. Now I just have to find a pop up piston or get the cylinder machined...:msp_sneaky:

personally dd i don't think these little saws are worth putting that much into them unless you just want to see how far you can push it without it coming apart:msp_biggrin::msp_biggrin:

Forgive my ignoreance, but what is squish and what is a pop up piston?

personally dd i don't think these little saws are worth putting that much into them unless you just want to see how far you can push it without it coming apart:msp_biggrin::msp_biggrin:

Good training wheels...For me anyway

Hahahaha! Damn it, spell check did not go through this time!

Forgive my ignoreance, but what is squish and what is a pop up piston?

If I can win a couple more without getting my shorts sniped on the bay I intend to cut a pop up for one of these things and machine the base of the cylinder, I'm thinking they would run really nice with compression in the 175 range and a larger carb. Has anyone checked the thickness of the piston to see if cutting a popup is possible without adding material? I've cut a few for trimmers and recently one for a cutoff saw and all had plenty of room to chuck up and cut away.

Me, too. I can't weld that thin stuff so I have to go with the old heat and bend method. It's slower but it works and doesn't look too bad when I finish. The muffler mod is a MUST on these. The muffler is incredibly restrictive, which may be why we're getting them. Maybe this batch didn't meet emission standards and they had to dump them on the market. Combine those with some customer returns, call them "Sold as is, for parts" and you've got the makings of an internet / CAD love story.

I checked compression and squish on mine, which as most of you know has been ported, muff modded and base gasket removed. The compression was around 150 out of the box and now sets at a respectable 162 psi cold. There is much to be gained, however, 'cause squish is .039 with no base gasket.

I'm glad I didn't raise or lower the ports on this one. Now I just have to find a pop up piston or get the cylinder machined...:msp_sneaky:

It's not that hard to weld sheet metal. You are basically just 'tapping' the trigger (MIG) for a small spot weld. (I would even attempt this with a stick welder) Hit each corner to start then half the distance between those welds then half again, etc until you have a line of spot welds. Trying to do a line of spots in a row usually heats up the metal too fast and burns through, hence the alternating. Then you grind the welds flush. This how body panels are welding in on vehicles. It does take some practice but it's not really that hard. The smaller MIG machines are easier to work with; mines a Hobart Handler 210 set at 2/20. I probably should have backed off the feed speed to 15 but it worked so...Someone with a lot of TIG welding experience could do these a lot prettier and not need to grind the welds down but IMO it would be a waste of time/expense on this saw.

I suck at braising...tend to burn holes with the torch

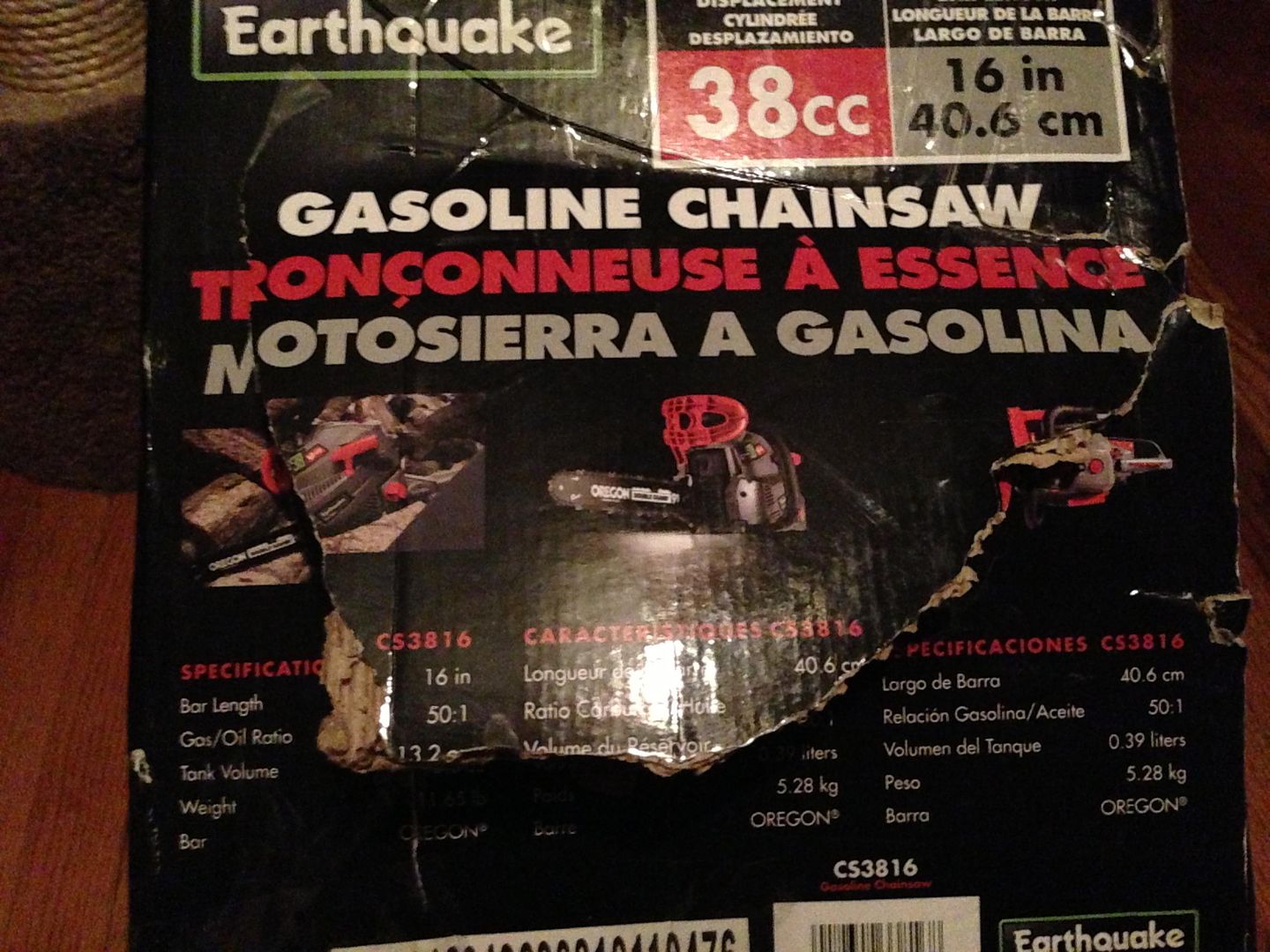

Experienced another Quake here this evening.

Box looked like it'd been through one....

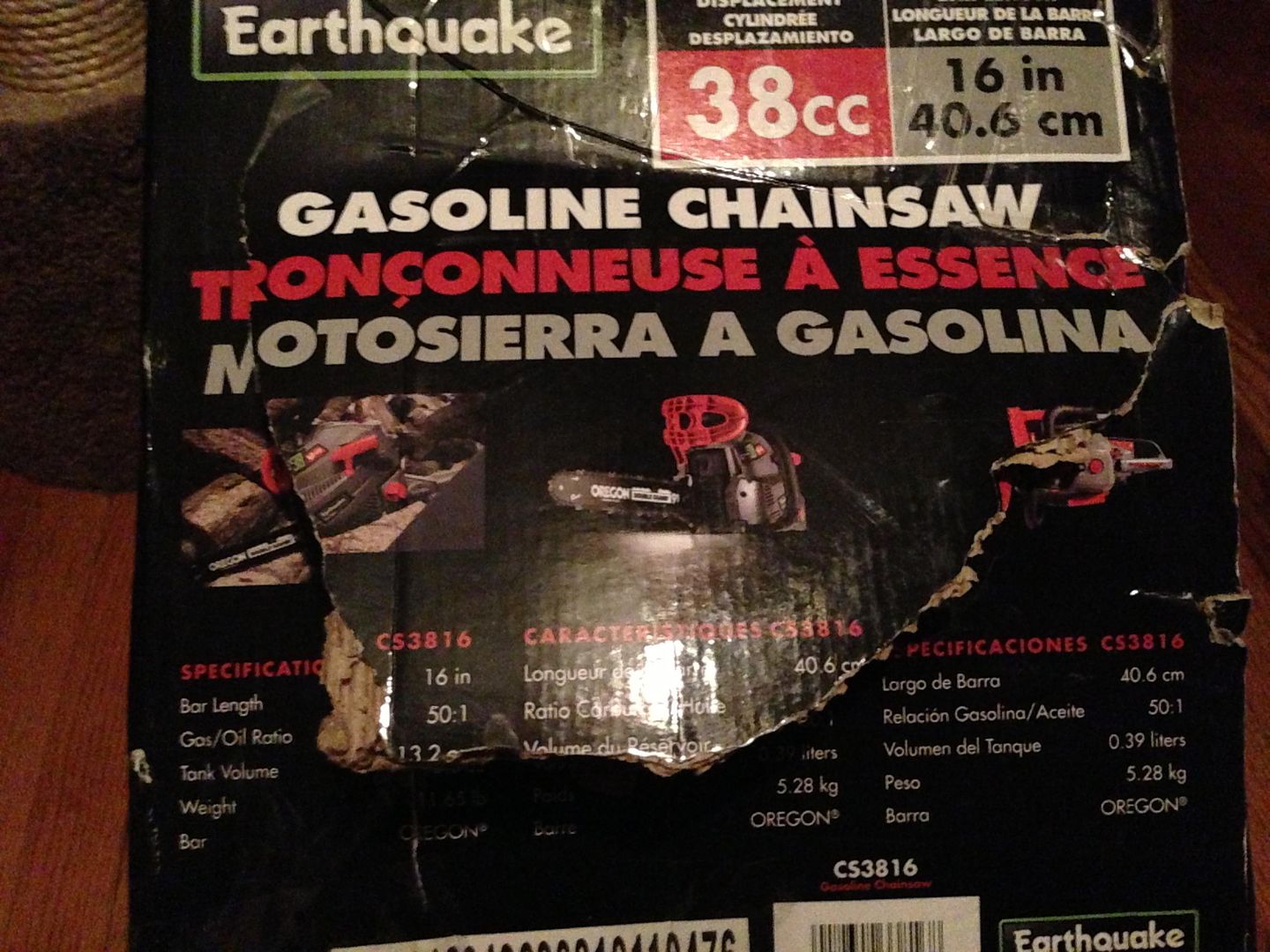

Contents.

First one was pretty much pristine, but this one had looked to have been sold, ran, but not to cut wood. Had the Sears tape one it and someone wrote the purchase date and serial number on the manual. Chain wasn't in original packaging like my first one, no file, or oil, but who knows, could have fallen out of the box.

This one has some issues it seems though.....

Enter your email address to join: