MG porting

ArboristSite Guru

OK I'll check her out tomorrow. Thanks for the info didn't see this one. Lol

OK I'll check her out tomorrow. Thanks for the info didn't see this one. Lol

Man I'm really tired. Lol I didn't get what you meant. Lol. But I do now. I'm slow you guys can slam me for it. LolOK I'll check her out tomorrow. Thanks for the info didn't see this one. Lol

well good, have you pulled the muffler? this is not giving a warning...unless you see it

Thanks checking. I will mine and report in tomorrow. I want to be happy too. I already had trouble so I was skard of more trouble. It's to.evto let me be so I can relaxYes popped it off and took a look. Still looks like new. So very happy thus far. Going to get a solid 5 tanks through it before I try milling with it. I will pull the muffler again at about 5 tanks and get a good look. I will be putting the new milling pipe on at that point to. Will keep you all posted.

LolMan I'm really tired. Lol I didn't get what you meant. Lol. But I do now. I'm slow you guys can slam me for it. Lol

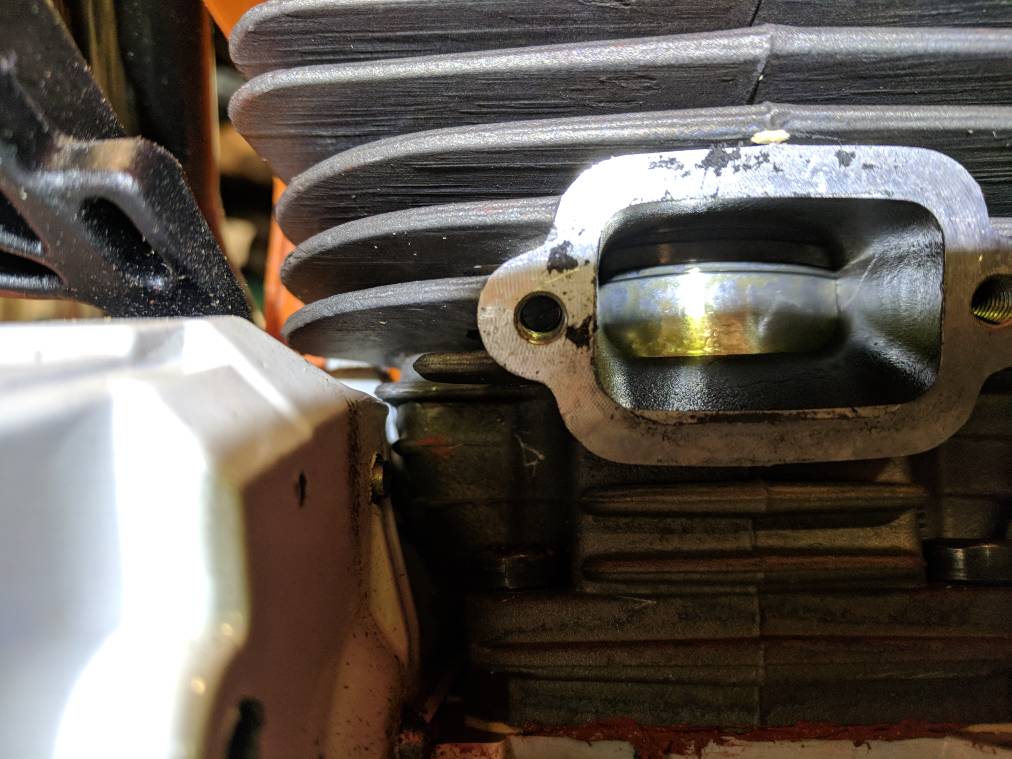

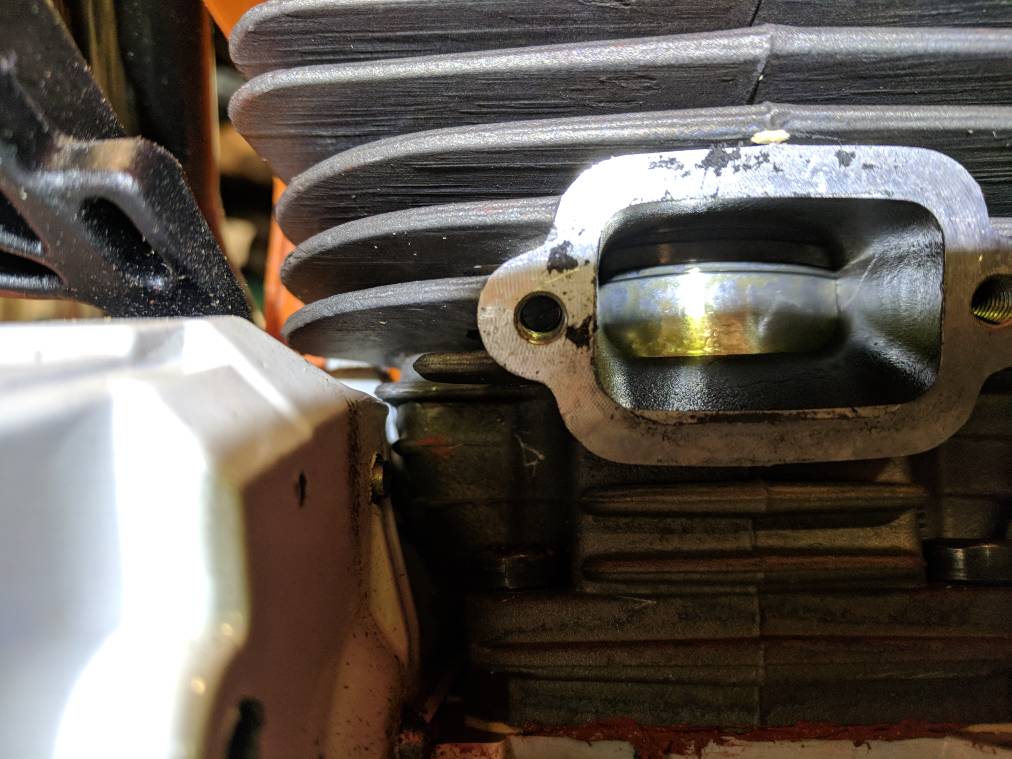

Yea keep a close eye on it I'm going to be thumbing through the web today and see what I can find on prices for piston and cylinder wish me luck. LolI do have light scoring about 4-5 mils below the rings, photo of exhaust side. As I rolled it the skirt was bright and shiney. Will need to watch it. Sure runs good. It cranked up on the 4th pull. I was going to mill today and can not get my 070 started. Something is wrong with the decomp.it wants to break my arm. Guess I will just do yard work

kit info & packing lists @ http://thechainsawkitguy.com

Yes sir, show me what you get. We might be twinsYea keep a close eye on it I'm going to be thumbing through the web today and see what I can find on prices for piston and cylinder wish me luck. Lol

Lol. Will do have to wait till next month which is not to far away now but I'm going to have a good idea of what I'll be getting and the beautiful woman who understands me is giving the OK so I'm definitely not going to be passing that up. LolYes sir, show me what you get. We might be twins

kit info & packing lists @ http://thechainsawkitguy.com

I think the bearing is not made to endure the extra compression. It's a good bearing. You are right the cranks are cheap but it's a pain to tear it down. So the top was the cause of my problem. And many reports the guys were being all political and had such a mix of parts they were unsure what caused the problem. I believed from day one with the right parts they would be runners and I have seen that be true over and over until the top problem came up. It would be a single production run in my thinking so not pandemicSo looking around on a group of 660 owners and reading a bit about big end rod bearing failures. Some comments have been made that it is failing due to to much compression. That it cannot take the cylinder being milled and compression to high. Now I don't agree with this because of a couple of reasons. One being if I bolt a 56mm top end on I am technically loading the bearing harder just the same right? All things being the same not touching the so called stock squish. Bigger piston more power more load and guys are doing fine with them.

Two. The "stock" squish is all over the place. Some guys reporting .020 right out of the box while others are as high as .037 out of the box. So you could not say what the base line is for a "safe" stock setup. I ended up with a very big squish. .034. I took it down to .026. I am happy. I am not after max power I am after long life. So I am leaning to the conservative side. What do you guys think on this?

I personally think its more of the random flawed parts. Bad hardness, bad bearing pin maybe not a perfectly round pin or pins, out of round rod end. Very similar to the cylinder issues. Overall I don't mind tinkering with it. Cranks are cheap so are cylinders. If I get even 5 gallons before some work though it I will be happy. Used 660 here is $900 minimum. No bar. I have $450 in my entire setup with a 42" bar. Wj-76 carb, oem wrist pin clips and bearing, oem gas cap, brake spring, oem Decomp, ho oiler. Figuire its going to last me awhile.

There is a lot Right about them.The way the come out of the box they are still faster than a Homelite Zip with less wieght.

I believe farmertec has two different crankshafts for the ms660.So looking around on a group of 660 owners and reading a bit about big end rod bearing failures. Some comments have been made that it is failing due to to much compression. That it cannot take the cylinder being milled and compression to high. Now I don't agree with this because of a couple of reasons. One being if I bolt a 56mm top end on I am technically loading the bearing harder just the same right? All things being the same not touching the so called stock squish. Bigger piston more power more load and guys are doing fine with them.

Two. The "stock" squish is all over the place. Some guys reporting .020 right out of the box while others are as high as .037 out of the box. So you could not say what the base line is for a "safe" stock setup. I ended up with a very big squish. .034. I took it down to .026. I am happy. I am not after max power I am after long life. So I am leaning to the conservative side. What do you guys think on this?

I personally think its more of the random flawed parts. Bad hardness, bad bearing pin maybe not a perfectly round pin or pins, out of round rod end. Very similar to the cylinder issues. Overall I don't mind tinkering with it. Cranks are cheap so are cylinders. If I get even 5 gallons before some work though it I will be happy. Used 660 here is $900 minimum. No bar. I have $450 in my entire setup with a 42" bar. Wj-76 carb, oem wrist pin clips and bearing, oem gas cap, brake spring, oem Decomp, ho oiler. Figuire its going to last me awhile.

They make some of their parts and buy some of their parts. I have seen the parts change over time from the first kits sold. All the parts have changed multiple times. They have even had at least two handle/tanks molds which is the most expensive part for them to produce. Some were improvements and then those improvements sometimes back slid. The different cylinders are mind blowing, that has been constantly changing. I will say this. They have never changed the spike package that shorts you the nuts. They were short in the first kits and are still missing. I could go on.I believe farmertec has two different crankshafts for the ms660.

Enter your email address to join: