We're not allowed to link to that other Forestry-related Forum, but here's one of the conversations they had on the subject of cutting beams.

OP:As you can see I am new at this. Will the beams bow if after squaring the poplar log I cut it into quarters?

R:Chances are, it will open up like a banana peel.

OP: That is what I am worring about. If I make a beam out of the heart and cut as many beams as I can from the rest of the log should this help to prevent bowing?

R: I recently cut several 6X6 beams 9to13 feet long from poplar and found that a 12X12 quarterd did bow quite a bit, just like Magicman said. But by cutting them oversize and re-sawing after drying a bit I was able to make usable beams. I also cut some smaller logs and boxed the heart and they were more stable. Boxed heart from a larger log will be more stable also.

(but anything over a 2X likes to split as they dry)

R: I failed to ask how long. The longer that they are, the worse it can be. I once split a 20' Poplar 12X12 cant into 6X6's. The results were not pretty, or usable.

R: I cut all of the beams for my cabin by boxing the heart of smaller logs...usually in the 12 to 16" range. They have stayed remarkably straight. I have not tried quartering a log for beams so I have no real experience with that but what others have said makes sense to me. Most of the beams have minor or no cracking but a few have really big splits and I have no idea why some split while others did not. It seems like I cut and treated them all the same.

R: Would not know what a poplar log is even with one fell on my head Not sure about dat one... Not sure about dat one... But with Doug Fir beams have to come out of heart any sap wood left and you just built a boomerang

R: Sometimes having Customer standing behind me when I am cutting out beams sometimes just pushes things to the limit. Have had situations where customer clearly sees two or three or even four beams in a log when I see only one. Even if I tell him, Customer doesn't seem to know I have made up my mind even before I get there, that I am not going to saw his logs into bowed beams, or waste a nice log which will surely give a nice beam out of the center but might give no beams if I try to get two or more out of it. Customer sometimes thinks all the trim cuts and 1x or 2x lumber were unnecessary. Mostly my work is hourly and I like it that way for beams and most everything else (and everyone agrees to it, and it works fine with almost everyone). But Customer seems to think sometimes beam means 4 cuts. What to do? Offer to demonstrate what happens cutting it his way? Offer to let him tell me how to make every cut on a log?

R: My limited experience with making beams from poplar has convinced me that you get one good beam per log. Box the heart and make a lot of nice siding or trim 4/4 stuff in the process.

R: I was thinking, one of these days, I might try quartering through the center vertically and horizontally, then strapping them back together (and stickered both ways) in the same configuration that they came out of the log, and keeping them strapped tight. Wouldn't this keep the stresses balanced enough to keep them straight? Has anyone tried this?

R: No.

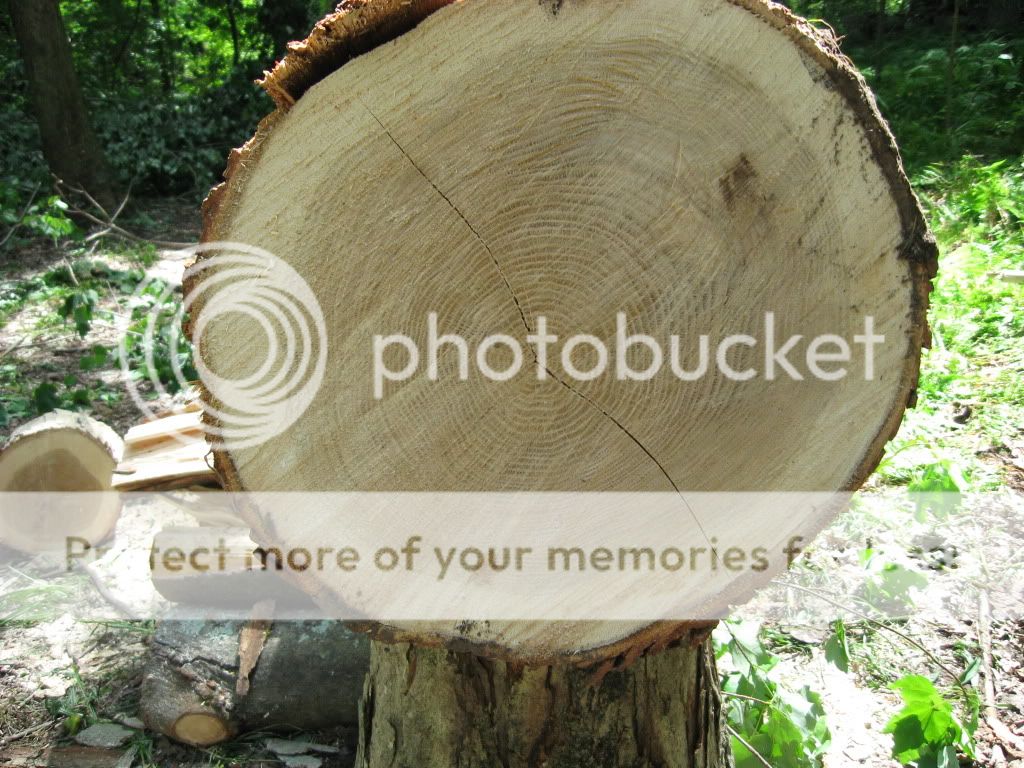

R: Trees lay down layers of wood that are in tension (maybe natures way of adding strength to a standing tree). When the wood is sawn from the log and is free to move, the tension releases causing the curve.

R: I've always been a Missourian at heart so I tried quartering to get four beams out of one beautiful red oak log I'd acquired- still haven't figured out what to do with the nice bow-beams I ended up with. Must be some use for a 4X6 beam that length... maybe we should have a brainstorming session on that- come up with some new uses for such demonstration pieces, than we won't look so foolish when we do it- "Oh, yeah, I meant to do that..."

Another thread by a master timberframer, we aren't allowed to link to it, but if you happened to stumble upon that other forum, search for the thread "Boxed heart beams or not" by Jim Rogers. The consensus of that thread is that boxed heart is generally best, free-of-heart may work if the log is large enough, but some logs will warp no matter what.

). All heart centered.

). All heart centered.

That tree has some residual stress.

That tree has some residual stress.