Philbert,

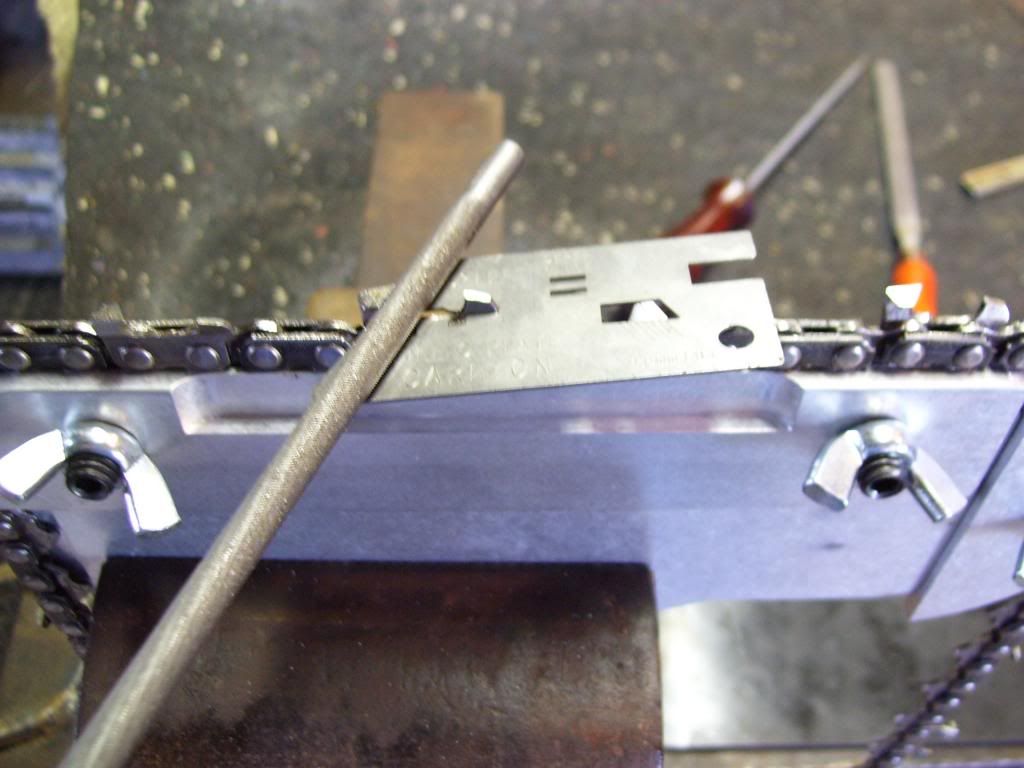

The full radius end is for tunneling a race chain or freehand square fileing! The smaller radius on left end in your picture is simply for chain flow!

Thanks!

I always learn new things on A.S.! Until I saw your photos it was not clear to me why someone might want to file on the radius. I assumed a flat vise would be sufficient, as most of those in that thread I linked show.

Now I see where it could be a real advantage for square ground and race chains (although, I am usually content with chains that cut firewood and storm damage at a stock level!)

Philbert