You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I'm thinking about building my own splitter.

- Thread starter MrGiggles

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

mga

wandering

this is how i made mine. if i were to change anything, i'd weld the sides. i used bolts in case i needed to replace the spacers....

I showed my dad my design and he said that I should reverse the wedge and plate, so the wedge is connected to the cylinder and plate is stationary. He said this way the splitter won't push the wood. Good idea?

sawinredneck

Addicted to ArboristSite

It depends on what you are after. I designed the monster with the wedge on the end, the idea being finished wood would land on the trailer or in a pile.

I like the wedge on the end because I don't have to handle the wood (in my opinion) as much.

I like the wedge on the end because I don't have to handle the wood (in my opinion) as much.

wkpoor

Addicted to ArboristSite

My first year I borrowed a splitter with the wedge at the end. Spent alot of time with a sledge hammer beating off the stuck pieces. That year I had alot of stringy elm to deal with. The next year I used one with the wedge attached to the ram. Any pieces that got stuck I could just extract on the retract. I throw each piece on a big pile anyway so its just as handy for the split pieces to end up in my hand as on the ground.It depends on what you are after. I designed the monster with the wedge on the end, the idea being finished wood would land on the trailer or in a pile.

I like the wedge on the end because I don't have to handle the wood (in my opinion) as much.

Here is the one I made... Check it out. You might find some ideas that you can use.

http://www.arboristsite.com/showthread.php?t=73006

http://www.arboristsite.com/showthread.php?t=73006

when a piece gets stuckon the wedge, i just grab another log and spilt it. it pushes the log thats stuck right off the wedge.

Here is the one I made... Check it out. You might find some ideas that you can use.

http://www.arboristsite.com/showthread.php?t=73006

I like your splitter a lot, I think it will influence my design.

You used just square tubing for your frame, which is probably a lot cheaper than a huge piece of I-beam, and easier to find. I might be able to make my splitter like yours using that instead.

Last edited:

wkpoor

Addicted to ArboristSite

Its stuck because it can't split it in the first place. Putting another piece in won't add any more power to the splitter. I fail to see how that would help. One time on the other style I had a piece so stuck I couldn't pull out of it.when a piece gets stuckon the wedge, i just grab another log and spilt it. it pushes the log thats stuck right off the wedge.

I like your splitter a lot, I think it will influence my design a lot.

You used just square tubing for your frame, which is probably a lot cheaper than a huge piece of I-beam, and easier to find. I might be able to make my splitter like yours using that instead.

The square tubing is from the horizontals used in industrial pallet racks. You should be able to find some cheap.

I took some that were left over from my wood stacking.

The axel and tires are from a mobile home that I shorten from 8' to 6'

View attachment 89821

Last edited:

Dan_IN_MN

Addicted to ArboristSite

Here's the splitter I got off of CLs

Here's the splitter I got off of CLs. It's not as powerful as I would like. I bought a PSI gauge and am going to find the "weak" point(s) and fix/replace them so this thing will split anything.

RED CIRCLE One might not be able to see it in this picture but the previous owner(s) used a hammer to "help" split. The metal is mushroomed.

YELLOW CIRCLE Starting this thing when it's cold is a pain because the fact a rope has to be wrapped for each pull. I put a belt on front and put an 110 volt electric motor on it. That helped with the cold starting.

BLUE CIRCLE I don't know why these small engines have such a loud muffler on them! What about putting a muffler for a small car on it by running a pipe under the splitter or else where?

GREEN CIRCLE Any one know which carb the Wisconsin engines used? Yes I do have an air cleaner.

Here's the splitter I got off of CLs. It's not as powerful as I would like. I bought a PSI gauge and am going to find the "weak" point(s) and fix/replace them so this thing will split anything.

RED CIRCLE One might not be able to see it in this picture but the previous owner(s) used a hammer to "help" split. The metal is mushroomed.

YELLOW CIRCLE Starting this thing when it's cold is a pain because the fact a rope has to be wrapped for each pull. I put a belt on front and put an 110 volt electric motor on it. That helped with the cold starting.

BLUE CIRCLE I don't know why these small engines have such a loud muffler on them! What about putting a muffler for a small car on it by running a pipe under the splitter or else where?

GREEN CIRCLE Any one know which carb the Wisconsin engines used? Yes I do have an air cleaner.

Last edited:

rdbrumfield

ArboristSite Operative

ok, finally did get the pic to work. I did post in another place so this will be redundant if you have been there.

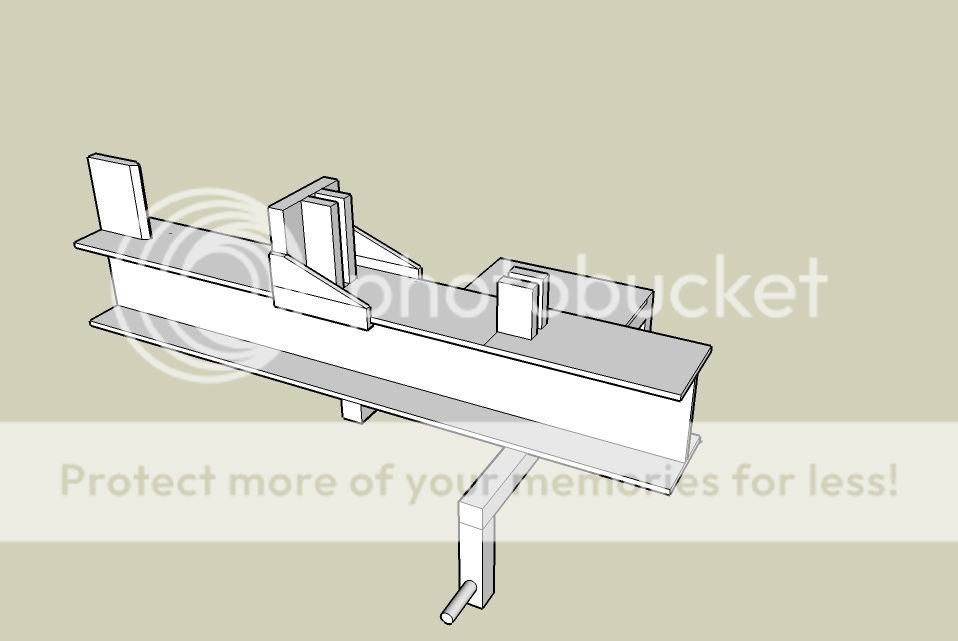

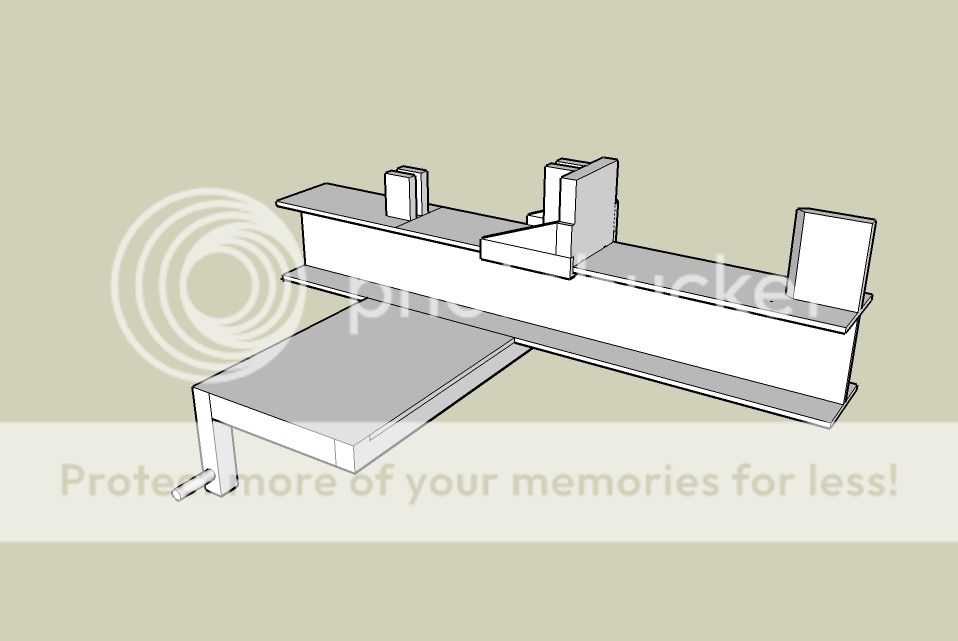

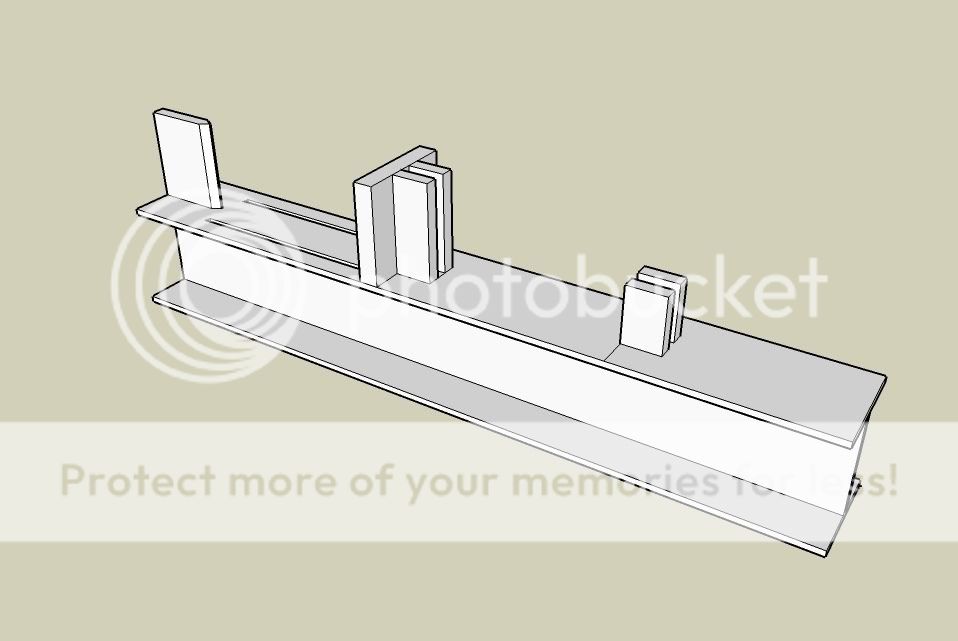

Make sure you put a couple off gussets on the beam near the end where your wedge is to add strength and to keep your beam from flexing.I've been fooling around with Google Sketchup and I think I have come up with a design that I want to build. What do you guys think of it?

You don't want to cut into the top of the beam for your slide as it will lose it's strength. Build some sort of guide for your mobile end of your cylinder to slide on.

Ours is set up for a 3 point hitch and sometimes it's a mobile crane also. We now run a v-twin 16 hp propane motor and hydraulic pump instead of the tractor also, that burns less $green$.

Check Craigslist, junkyards for old construction and farm equipment and some "shadetree tecknowledgee" and you'll do fine.

jwfirebird

ArboristSite Lurker

"Check Craigslist, junkyards for old construction and farm equipment and some "shadetree tecknowledgee" and you'll do fine."

thats the thing there, always be looking for deals. i found a 11hp honda engine for mine on a water pump someone was going to throw away because the pump was bad.

thats the thing there, always be looking for deals. i found a 11hp honda engine for mine on a water pump someone was going to throw away because the pump was bad.

Similar threads

- Replies

- 19

- Views

- 2K

- Replies

- 93

- Views

- 4K

- Replies

- 3

- Views

- 631

- Replies

- 17

- Views

- 2K