Jim Timber

1/4 bubble off

I run a 16" on my 50-60cc saws. If I need more bar, I probably want more cubes too.

Some people just have to hate by nature. Must be a miserable life. Too bad he can't understand doing it just because it's something you enjoy. I've been doing build thread much longer than I've been a sponsor.

Yes, that is also partly the idea too. R&D in Sweden watch the arborist forums all over the world, and porting is gaining in popularity, especially with the videos and images on how to do the improvements. The saw only needs to meet emissions laws until purchase.

In fact, I would go as far as saying brad probably helped the 201t improvements! After all, if the manufacturer can save a few million in R&D by watching what basic mods a porter has used

Sent from my iPhone using Tapatalk

Everyone is predictableCareful there brad, I can hear your panties scrunching up from here.

I've been around and your benevolency has always been rewarded 10 fold.

You see I do it for the love of making something useless 'mobetter'.

You on the other hand do it for $$$$$$$$$$$$$$$$s.

Yep I can be a curmudgeon at times but when I need a good chuckle I just log on and poke you in the eye.

Sheeez you are so predictable!

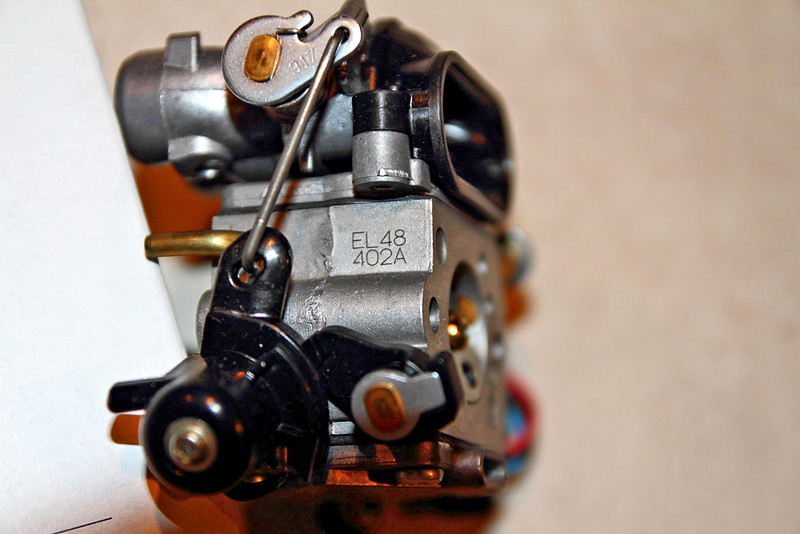

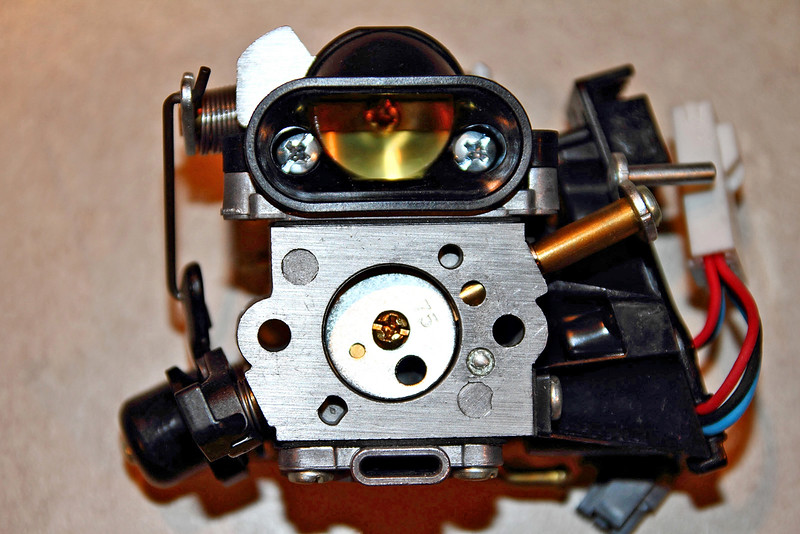

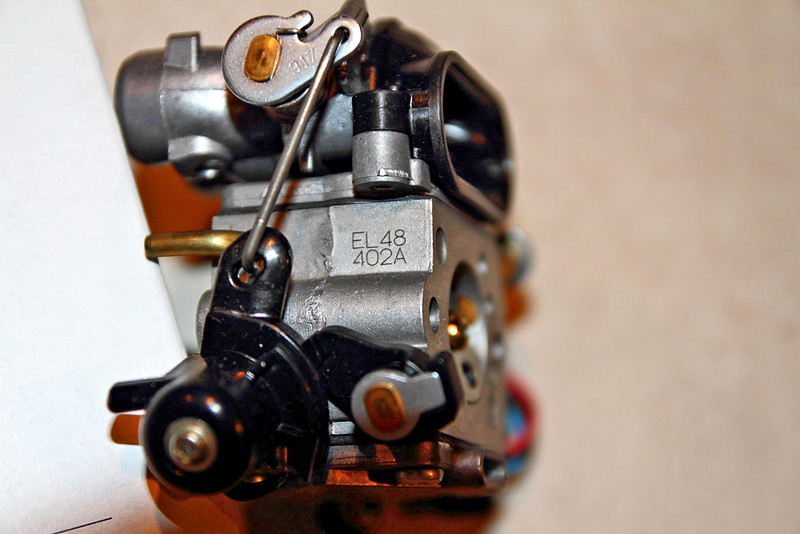

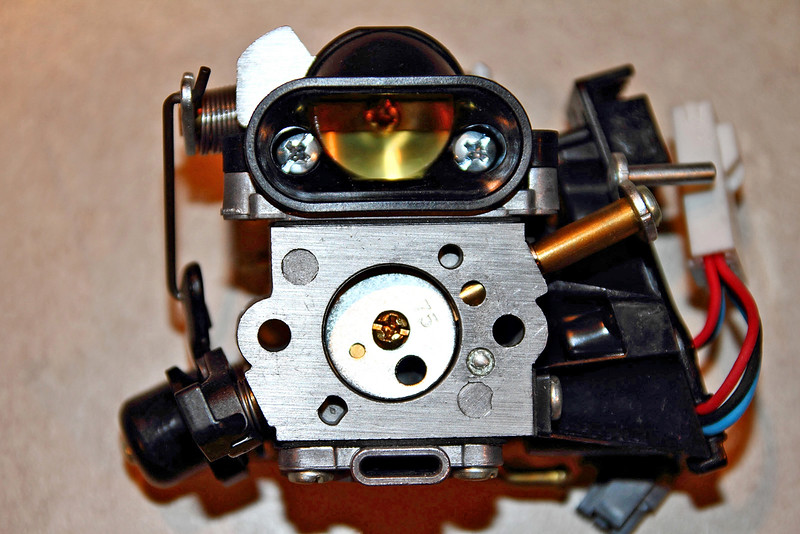

Here's the 2260 ported. Don't advance the ignition on your 2260s or 562XPs. Also, I added a small notch in the butterfly directly inline with the transition passages. The hesitation remains. Looks like I'm going to have to pony up for a EL48.

You forgot to send me your programmer loaded with EL48 firmwareugh, well, ugh,,, is it faster than stock??

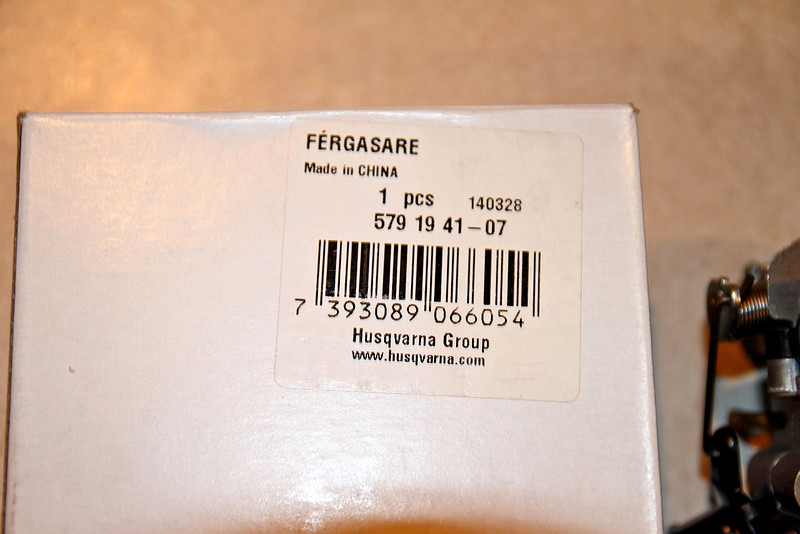

Hutzl is getting pretty good huh?Here's one of those EL48 carbs from EBay for $69. Now to get the module programmed.

Thanks for this information, there is a lot in here and I have not read them all yet. There is some basic stuff that may impact on the 562 problem, relative to strato engines in particular. With strato engines there are two paths for air to enter the engine, one which carries not fuel at WOT (the strato ports), and the traditional path that carries a reduced airflow into the crankcase which carries all the fuel at WOT. However, the fuel and air flow are configured differently at idle vs. WOT. There are two approaches used:Yet the 241m, 441 and 661 I've seen all had walbro.

If you want to disagree fine, but why is autotune patented but m-tronic only trade-marked?

Also, you can check various patent listings, I did before posting the reply. So I believe this time, you're full of it!

20140209078 <- autotune that's currently used

20140183315 <- magnet and sensor for the adjustment whilst running

20130332049 <- Rev-limiting autotune

20130133618 <- autotune memory/stats

20120318143 <- the current x-torq

20120304966 <- ignition timing control

20100011597 <- more autotune stuff!

20090145399 <- an autotune patent (this is what Stihl use)

20080302345 <- older form of the new x-torq

Oddly, Stihl own the patent for the x-torq that the 372xp uses:

20100242904

But this patent only happened in 2010, so I assume it must have been sold and transferred into Stihl's name

Sent from my iPhone using Tapatalk

From what I've seen you are on the right track.

Just adding to what you posted......

"They have clearly been drilling holes in the throttle plate".....

And notches. The extra air that has been introduced must raise idle speed.......there ain't no way around that. To compensate, I believe that the AT system adds more fuel. That added fuel pools behind the throttle plate. Crack the throttle.......that fuel dumps into the case and causes a bog.

They can add all the bandaids they want.......but this issue is common, and tough to fix.

Enter your email address to join: