Since my boom grapple build is underway I decided to start a new thread instead of adding to my other thread. I figure this thread may get more traffic than the one titled "grapple boom help".

I had the bright idea to build this thing after using the truck to pull some logs off a pile then having to bend over to cut them to firewood lengths. I have a dump trailer I built a couple of years back and I'm going to put this on the tongue. I will do away with the electric over hydraulic unit on the dump trailer and power the grapple and dump with a gas powered motor hooked to a hydraulic pump. I have most of what I need here, I have a bunch of 2"x2"X1/4" angle iron I picked up cheap at the scrapyard this summer, the main lift cylinder which was given to me, the pump came in a hydraulic tank I used for my log splitter, a piece of 6" well casing that was given to me, 3/8" x 6" flat stock was left over from a previous project, I bought the 2 1/2" square tube for the boom, I had the jeep axle and the bearings were in a drawer that I had bought for a project that never happened.

Anyway, the plan is to get a HF 6.5 hp motor for 99 bucks, a backhoe control valve either used or new. I will need to buy a crowd arm cylinder and sabilizer cylinders, an adapter for the pump to motor and hoses etc. etc.

Here are a few pics of what is completed so far, I will get some more pics of the bearing set up for the base of the turret.

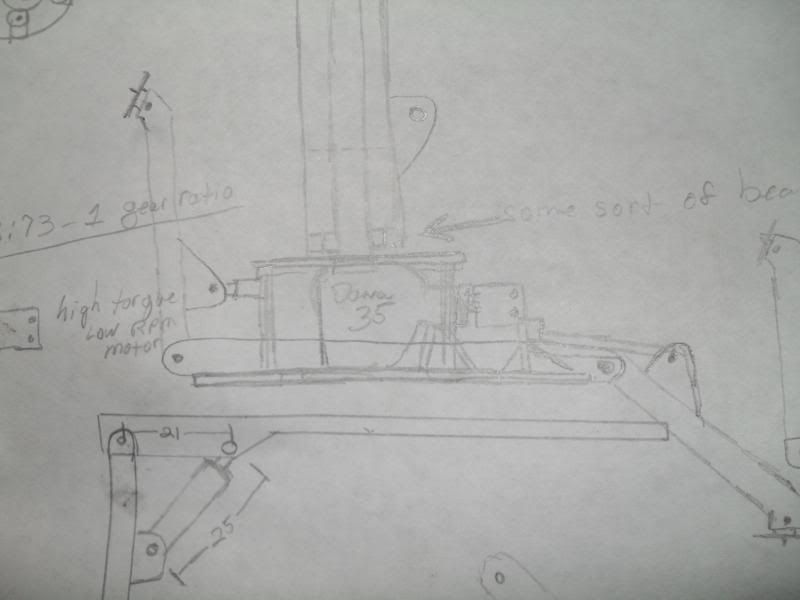

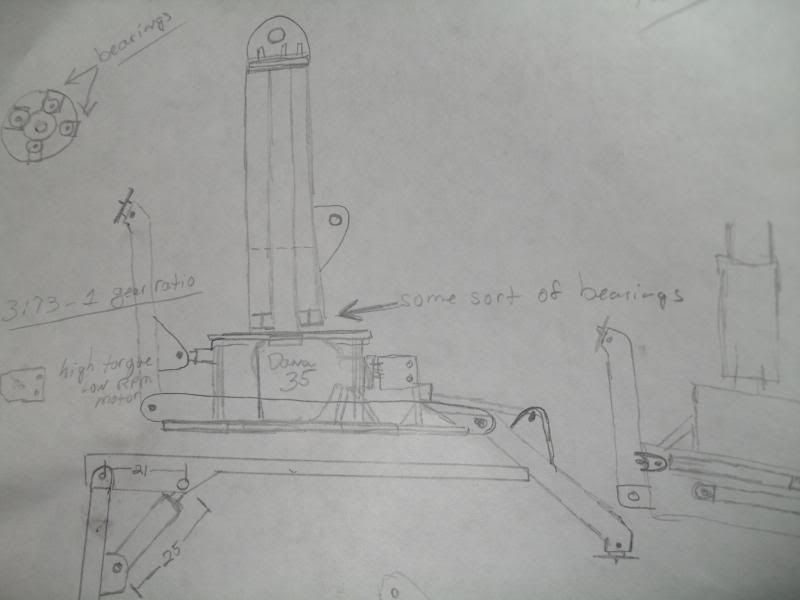

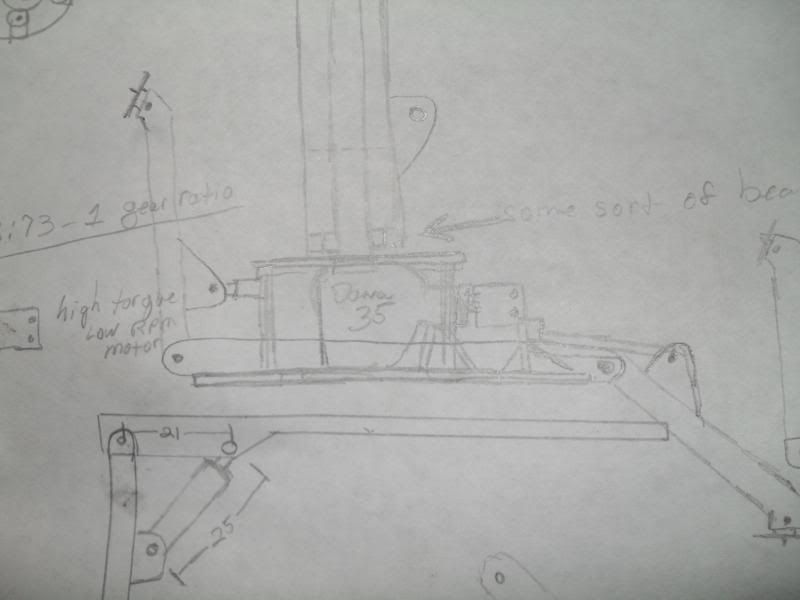

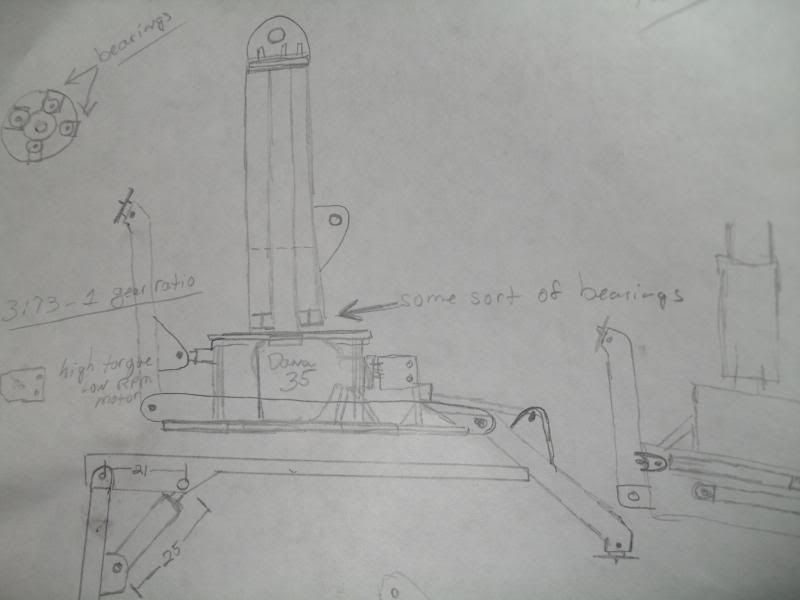

Here's how most of my projects start, a doodle. I doodle when I have my morning coffee! LOL

jeep axle cut down pass side

the 6" casing fit almost perfectly over the axle end where the brake drum would go

Plan is to weld the spiders, put a large chain sprocket on the yoke and drive it with a hydraulic motor, I'm trying to figure out the gear ratio and how fast the turret will spin. Given a 6:1 chain drive and a 3.73:1 axle drive I'm guessing somewhere around 24:1, I hope this will be slow enough. (I could use some help here)

I'm searching for the drive motor.

I will keep you updated as this thing progresses.

thoughts on stabilizer legs, folding or sliding, I'm thinking folding will be less weight?

dave

I had the bright idea to build this thing after using the truck to pull some logs off a pile then having to bend over to cut them to firewood lengths. I have a dump trailer I built a couple of years back and I'm going to put this on the tongue. I will do away with the electric over hydraulic unit on the dump trailer and power the grapple and dump with a gas powered motor hooked to a hydraulic pump. I have most of what I need here, I have a bunch of 2"x2"X1/4" angle iron I picked up cheap at the scrapyard this summer, the main lift cylinder which was given to me, the pump came in a hydraulic tank I used for my log splitter, a piece of 6" well casing that was given to me, 3/8" x 6" flat stock was left over from a previous project, I bought the 2 1/2" square tube for the boom, I had the jeep axle and the bearings were in a drawer that I had bought for a project that never happened.

Anyway, the plan is to get a HF 6.5 hp motor for 99 bucks, a backhoe control valve either used or new. I will need to buy a crowd arm cylinder and sabilizer cylinders, an adapter for the pump to motor and hoses etc. etc.

Here are a few pics of what is completed so far, I will get some more pics of the bearing set up for the base of the turret.

Here's how most of my projects start, a doodle. I doodle when I have my morning coffee! LOL

jeep axle cut down pass side

the 6" casing fit almost perfectly over the axle end where the brake drum would go

Plan is to weld the spiders, put a large chain sprocket on the yoke and drive it with a hydraulic motor, I'm trying to figure out the gear ratio and how fast the turret will spin. Given a 6:1 chain drive and a 3.73:1 axle drive I'm guessing somewhere around 24:1, I hope this will be slow enough. (I could use some help here)

I'm searching for the drive motor.

I will keep you updated as this thing progresses.

thoughts on stabilizer legs, folding or sliding, I'm thinking folding will be less weight?

dave

Last edited: