i am going to build a log lift . while searching the forum the log lift build post that came up were so old all the pics were not there any more. so i need some pictures and advice.here is my splitter. http://www.atwoods.com/logsplitters/black-diamond-25-ton-log-splitter.htm please give your advice or help or even some web links to help me git this built .i finally got my back surgery disc fusion . and still have 2 more surgery on my upper back to go.so lifting these huge rounds are going to have to be by a lift table. building the table is not were i need help . it is the hydraulics . the stuff i found is were it gets kinda iffie . thanks for the help if you can.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

log lift build

- Thread starter siouxindian

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Your splitter is a horizontal /vertical correct? Granted, I can't stand using a vertical but the lifting thing is avoided. I understand the rolling around on rounds ends is a pain as that kills my back after a few hours.

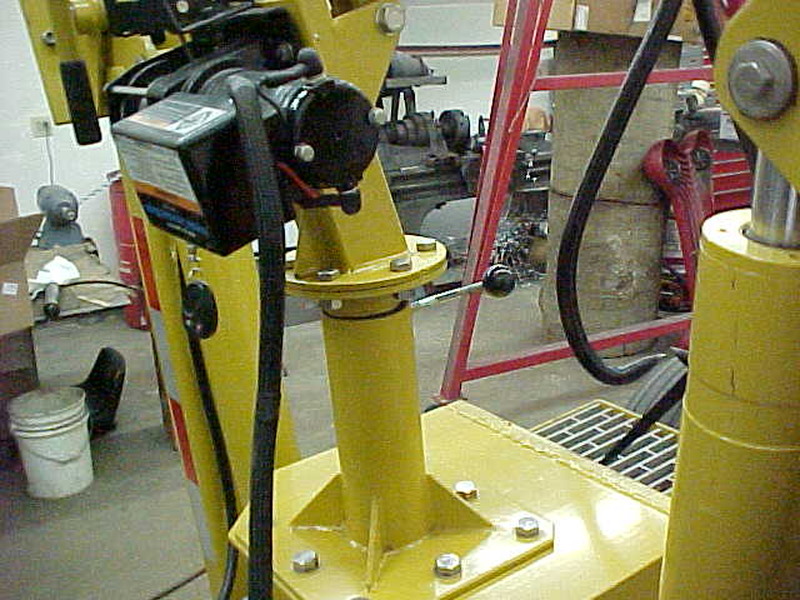

When I made my splitter I made a lift for it. The biggest issue you have is stability. I combated this with stabilizer arms.

I just used a cordless electric winch so I can drag them in and lift. Then swing 180 to the table. I just back down the length of the log and throw to the sides. When done, I back the truck down the same lane and load from either side. Works great for me. the electric winch is extremely fast but it does allow me to split stuff that normally one person couldn't even roll into position.

This is a 3ft diameter beech cut 24 inches long.

The hanger on the hook is basically an added storage while you split up the slabs till you're ready.

The normal lift on the side may be your best option. Personally I never cared for those as you are always stepping over them and seem in the way to me. You're still leaning over rolling them into position though.

You may want to consider a swing lift on a truck or trailer and then roll them level from that onto the splitters table.

When I made my splitter I made a lift for it. The biggest issue you have is stability. I combated this with stabilizer arms.

I just used a cordless electric winch so I can drag them in and lift. Then swing 180 to the table. I just back down the length of the log and throw to the sides. When done, I back the truck down the same lane and load from either side. Works great for me. the electric winch is extremely fast but it does allow me to split stuff that normally one person couldn't even roll into position.

This is a 3ft diameter beech cut 24 inches long.

The hanger on the hook is basically an added storage while you split up the slabs till you're ready.

The normal lift on the side may be your best option. Personally I never cared for those as you are always stepping over them and seem in the way to me. You're still leaning over rolling them into position though.

You may want to consider a swing lift on a truck or trailer and then roll them level from that onto the splitters table.

Like Kevin, I prefer a boom lift instead of side mounted log lift. Face it, If you have a side lift, you still have to roll that round to the lift, sure the lift will raise the log to position, but you kill yourself getting the log to the lift. With a boom and winch, you simply walk over to the round, hook up the log dogs and winch the log up on the splitter. You can buy one of those 2500-3500lb atv winches now for $100bucks or so. This is way cheaper than buying a hyd control valve, cyl and hoses to make a side lift work. I did notice the splitter in the link doesnt have electric start, so finding 12v to power a winch might be an issue. If you can work out the battery power, a boom and winch is the direction I would go

thanks you all. i been kickin it around just had to have someone else say it i got every thing to build that i got a 8 ton cherry picker ram.and a lot of 6011 rod lots a steel pipe.steel square tubing and several wenches. so i just gotta get building when i heal up from surgery still kinda sore.thank you again

im gona put a electric start engine on that splitter.when its in the 20s it real real hard to start i put lite weight oil its still hard to start.when in the 40s 1 pull start right up.

ChoppyChoppy

Tree Freak

How does a cordless winch work, it have a battery pack like a cordless drill?

How does a cordless winch work, it have a battery pack like a cordless drill?

The remote or controller is cordless. The winch is connected to the battery. Having the remote without a wire is nice when your dragging stuff in. Sorry for the confusion.

I sometimes just clip it to a tether around my neck or belt loop.

Any 12v winch I have seen will suck a battery dead pretty quickly. The charging circuits in most small engines are (almost) sufficient to keep the battery topped up between starts, but I doubt they would keep up with heavy use of a winch. Suggest you use a larger battery and wire it for a maintainer. Plug in the maintainer and top it off between sessions.

Not so sure about needing a larger charger. I use a marine battery on my splitter and I have never ran the battery down. I am running a 25hp kholer engine on mine, so that might make a difference.

On the remote, mine is on a 20ft wire and yes you have to be careful with the cable. I need to rig up a wireless remote of it.

On the remote, mine is on a 20ft wire and yes you have to be careful with the cable. I need to rig up a wireless remote of it.

Not so sure about needing a larger charger. I use a marine battery on my splitter and I have never ran the battery down. I am running a 25hp kholer engine on mine, so that might make a difference.

On the remote, mine is on a 20ft wire and yes you have to be careful with the cable. I need to rig up a wireless remote of it.

I use a normal car battery and I've never had any charging issues either. I'm running a 25 HP Briggs. I've run it quite a bit too.

ChoppyChoppy

Tree Freak

Most charging circuits on lawn tractor style engines are 10-15 amp max, and that's at WOT.

A small winch will draw 100 amps quite easily, 400-500 amps at full pull (ie stalling it)

Interesting that it works ok, I guess with not much use/short pulls it would be fine.

A small winch will draw 100 amps quite easily, 400-500 amps at full pull (ie stalling it)

Interesting that it works ok, I guess with not much use/short pulls it would be fine.

Have to get a picture, I made my spillter to set on the ground no lift needed or extra cyclinder valve hoses . I do like the winch ideal .

Last summer had a big oak fall in a storm had a 2 foot bar that almost wasn't big enough 2 rounds spilt would fill a pick up got 9 pick up loads out of the trunk . All I used was a cant hook to put the big rounds on the splitter . A winch would have been really nice

I think another thing to consider is you are just winching a couple hundred lbs or less most pulls, so it not pulling as hard as it would if you had 2500lbs hung off it.Most charging circuits on lawn tractor style engines are 10-15 amp max.

A small winch will draw 100 amps quite easily, 400-500 amps at full pull (ie stalling it)

Interesting that it works ok, I guess with not much use/short pulls it would be fine.

A large wheel, 2 wheel dolly works very well for moving stuff around. I use it in the timber to move 2-300 lbs. chucks to the lift. I've toyed with an electric winch as my Gx630 has 18 amps of recharge, but my cooler, when running, takes 18 amps.

what yall think about this one.https://www.harborfreight.com/2500-...Winch-with-Wireless-Remote-Control-61840.html

That is where I got mine the first round. I bought 2 at the time so I's have a back up. Something died in the remote where it wouldn't recognize it so I switched it out. I have had to change batteries in the remote several times. I bought another at a local farm store(different badging) so we'll see if it is the same or not If the one on the splitter dies. I did go through and upgrade the size of the wire feeding the winch from the battery. The wiring that comes with it is pretty small. Again, they do not spool fast but I have found it to be fine as going too quick with a 3ft + round isn't what I wanted.what yall think about this one.https://www.harborfreight.com/2500-...Winch-with-Wireless-Remote-Control-61840.html

If someone else is there it works fine to have them finish up the smaller chunks while I'm dragging the next one in and get it hanging, ready and waiting.

That winch should be fine but do yourself a favor and spend another 20-25 bucks while you're there and buy the synthetic rope, you will thank me later  Oh and use the 20% off coupon

Oh and use the 20% off coupon

I like this winch idea. Thinking about incorporating it into my build.

Most charging circuits on lawn tractor style engines are 10-15 amp max, and that's at WOT.

A small winch will draw 100 amps quite easily, 400-500 amps at full pull (ie stalling it)

Interesting that it works ok, I guess with not much use/short pulls it would be fine.

As Valley says - Lawn tractor style engines typically have 10-15 amp charging circuits. The cheaper predator style engines often have charging circuits limited to 1-2 amps.

It all depends on the engine you use, the size of the battery, and the frequency of use.

Similar threads

- Replies

- 7

- Views

- 1K

- Replies

- 93

- Views

- 4K

- Replies

- 1

- Views

- 413