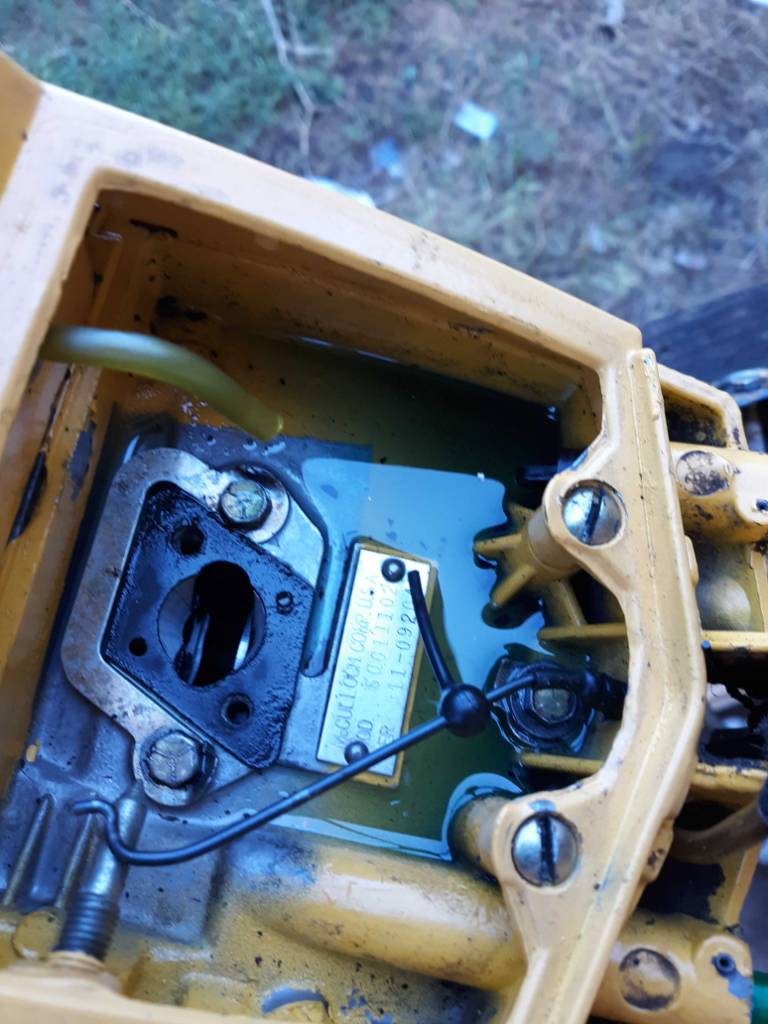

I have a kit but cleaned carb and all looked good.One turn on both is OK and shouldn't cause flooding. The usual culprits are,

Metering diaphragm not hooked into the metering lever.

Crud between the metering needle and seat.

Metering needle stuck open.

Sometimes the mix needle(s) and seat are damaged and let more fuel through.

Maybe mixed up order of gaskets and diaphragms.

Sent from my SM-S767VL using Tapatalk