SquareFile

ArboristSite Guru

I have a 1st year 441. Send it to me for R&D. Lol. Nice craftmenship.So sell it to someone with a standard 441?

I have a 1st year 441. Send it to me for R&D. Lol. Nice craftmenship.So sell it to someone with a standard 441?

So sell it to someone with a standard 441?

That's not combined unfortunately. The choices are tach/hour, hour, temp, or ambient air.I see that same company, TTO, has one that is tach, hours *and* temperature.

It is an awesome install. I fail to understand why anybody would need a tach installed on an auto tune saw in the first place. What are you going to do if you think the RPM's should be higher in the cut? Also please make sure you are focused on the saws intended purpose and not on the tach. Stuff can go wrong in a hurry when u'r not watching u'r tip. Kudos again on the great installation

It is an awesome install. I fail to understand why anybody would need a tach installed on an auto tune saw in the first place. What are you going to do if you think the RPM's should be higher in the cut? Also please make sure you are focused on the saws intended purpose and not on the tach. Stuff can go wrong in a hurry when u'r not watching u'r tip. Kudos again on the great installation

If it did work? I would pay to have one fit into my cover.

I'm sure there are a few standard 441 owners that would like one. Seeing how the Tach would work.

(Temp would be a nice option as well)

Excellent work!

I was just about to purchase that same tach in orange, too.

My only concern was that I couldn't find any info on the refresh rate.

Do you happen to know the refresh rate on this tach?

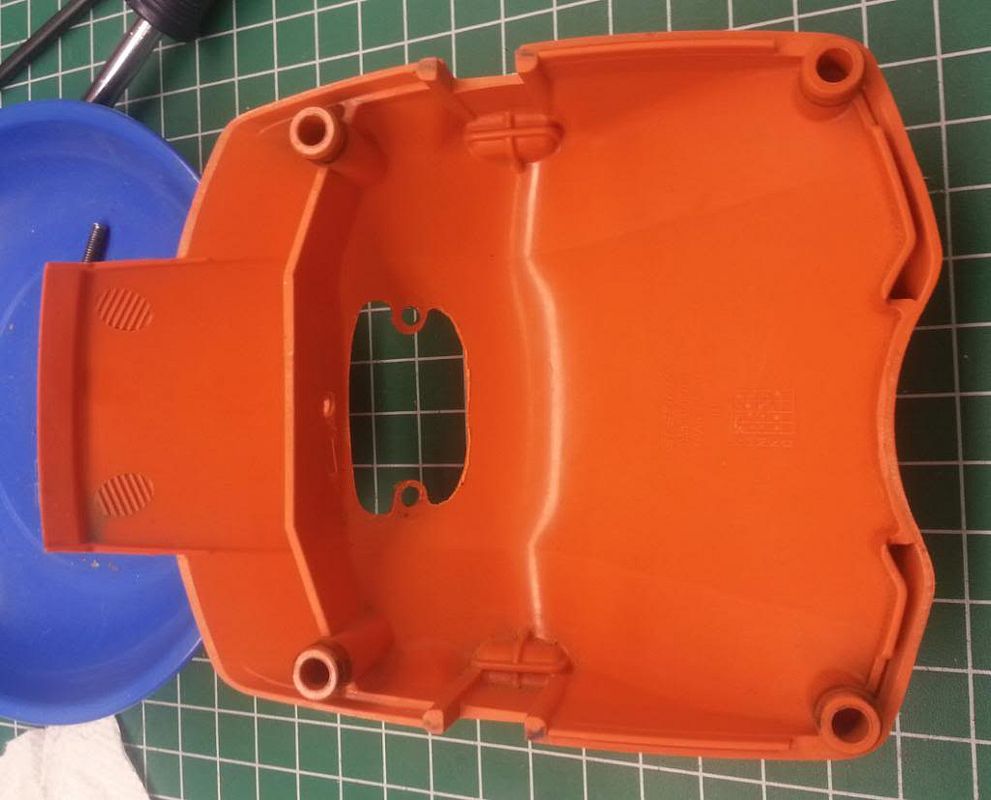

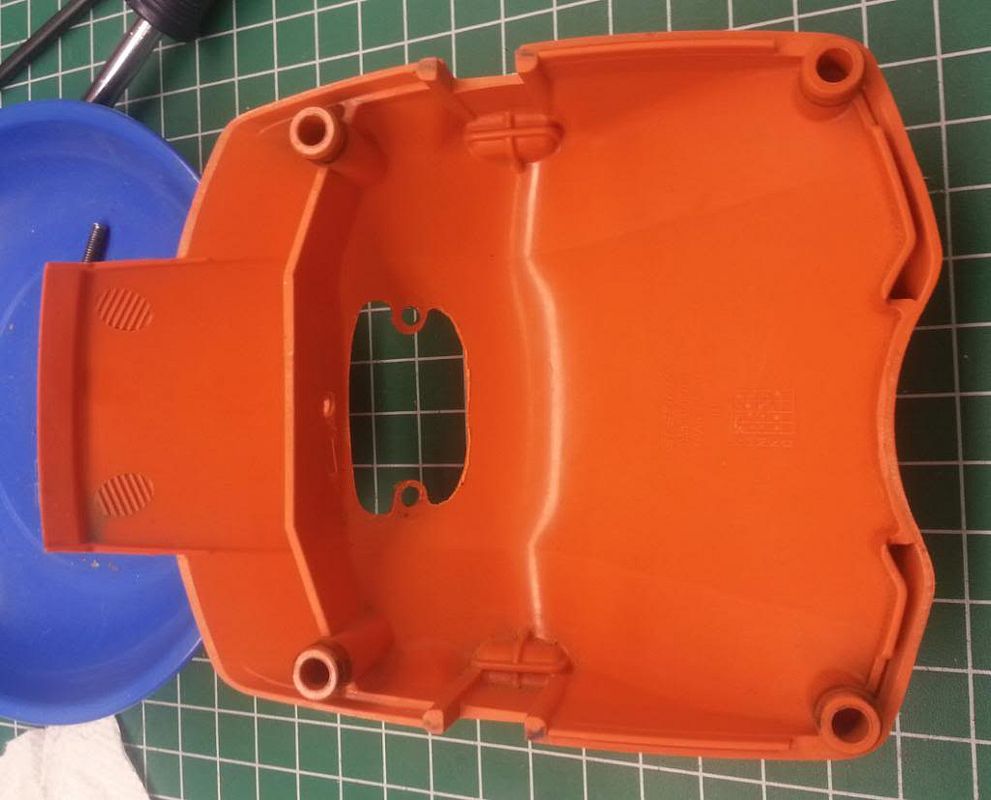

Sure!Very nice. Can u post pic of underside of cowl?

I use the tachs when I'm modding the carb. You can watch the rpm as you pull down the revs and determine peak torque and how fast the power drops off below peak torque. That can tell me if I need some extra fuel flow in the low speed circuit.

The same with the high speed circuit where I can tweak the high speed needle and pick up a couple of hundred rpm in the cut. My ears aren't good enough to pick up 200 rpm at 10,000 rpm - that's only a 2% difference.

Sure!

very clean and nice job!!!

Here is how it looks without the tach:

And with the tach:

Enter your email address to join: