Hello,

I am new to the forum. Found it while researching splitter building.

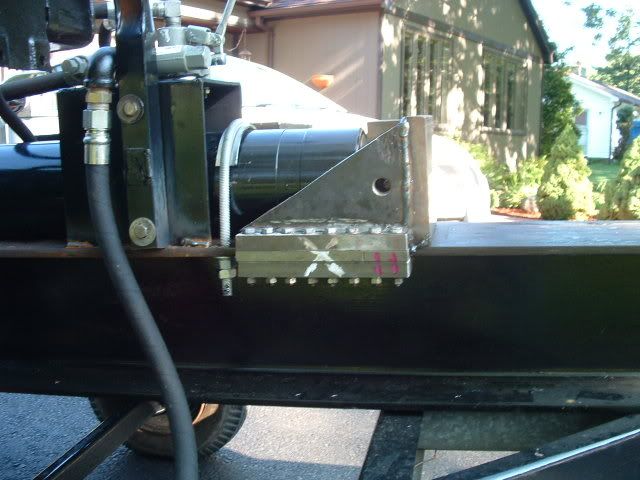

I have acquired some of the parts to start a splitter build and need to make a few decisions before I start cutting metal. Its going to be a pretty basic unit with an I-beam and fixed wedge. I have a lot of mechanical experience and access to some decent equipment so I am not limited that way. I don't have much experience with hydraulics, but I have been doing some reading. I'm probably going to buy a two spool valve because I want to add a log lift to it. My back is not getting any better or stronger with age.

The question I am faced with at the moment is which end should the wedge be on? It looks like the majority of the units I see pictures of have the wedge on the front end (the hitch end). It seems to me that there would be more room to work around the splitter if the wedge were on the back end away from the vehicle. The horizontal / vertical units generally face this way, but that is necessary so the foot can be tipped down to the ground.

Please give me the pros / cons as you see them.

Thanks

Jerry

I am new to the forum. Found it while researching splitter building.

I have acquired some of the parts to start a splitter build and need to make a few decisions before I start cutting metal. Its going to be a pretty basic unit with an I-beam and fixed wedge. I have a lot of mechanical experience and access to some decent equipment so I am not limited that way. I don't have much experience with hydraulics, but I have been doing some reading. I'm probably going to buy a two spool valve because I want to add a log lift to it. My back is not getting any better or stronger with age.

The question I am faced with at the moment is which end should the wedge be on? It looks like the majority of the units I see pictures of have the wedge on the front end (the hitch end). It seems to me that there would be more room to work around the splitter if the wedge were on the back end away from the vehicle. The horizontal / vertical units generally face this way, but that is necessary so the foot can be tipped down to the ground.

Please give me the pros / cons as you see them.

Thanks

Jerry