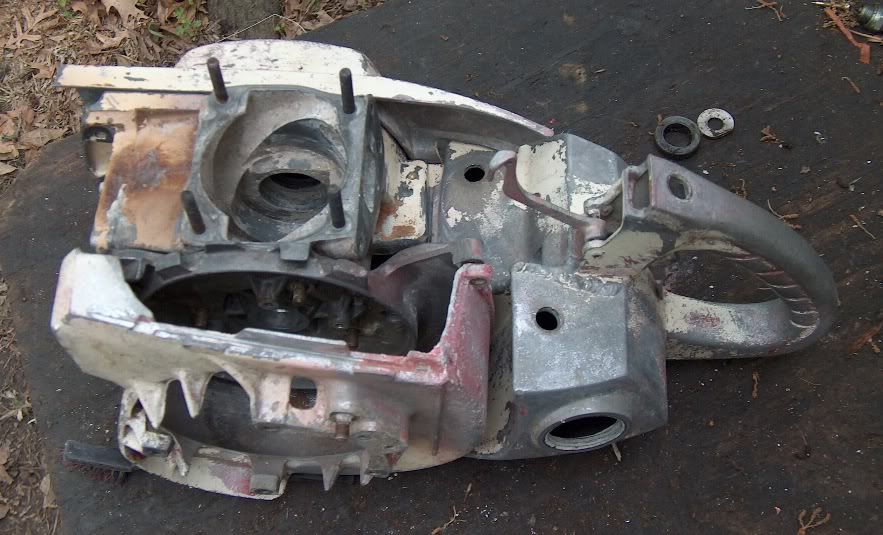

Most of you know what I started with:

Nasty paint and great compression. When I pulled the muffler and saw all the rust and scale I made up my mind to remove the head and cylinder to inspect the case and make sure it was clean. It wasn't, at all. Not much corrosion but alot of slime and build-up. I wasted no time and pulled it down to the crank. Here's what it looks like inside.

That white stuff on the crank just flakes off. Don't know what it is.

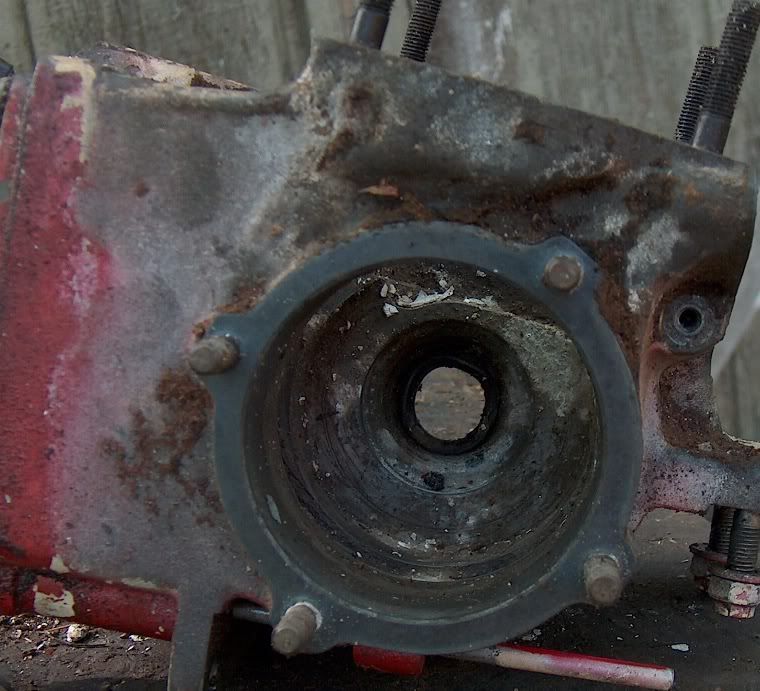

The piston looks great but the top ring is stuck. Got it soaking right now to get it loose. Here's a couple of the cylinder. Any discoloration you see is just that. I can't feel any roughness in the bore. Actually, I see a whole lot of cross hatching from the original factory finish. Bear in mind this thing is piston ported but the carb mounts to the crankcase.

Intake:

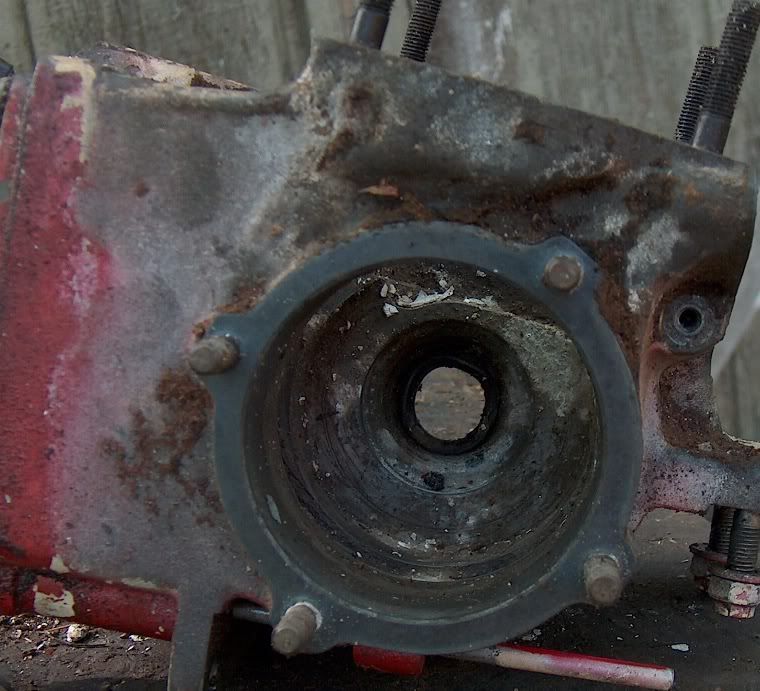

Exhaust:

Engine bearings are standard 6203 and I was able to match the seals to a CR number. I'm going to try something for the rod big-end needles--since I can't get loose needles, I ordered a bearing that should have the right diameter rollers. I'll cut that bearing apart and try to use the rollers in this rod.

I've already ordered all the bearings I'll need and even picked up the paint for this thing. It needs to get to a sandblast cabinet badly.

Chris B.

Nasty paint and great compression. When I pulled the muffler and saw all the rust and scale I made up my mind to remove the head and cylinder to inspect the case and make sure it was clean. It wasn't, at all. Not much corrosion but alot of slime and build-up. I wasted no time and pulled it down to the crank. Here's what it looks like inside.

That white stuff on the crank just flakes off. Don't know what it is.

The piston looks great but the top ring is stuck. Got it soaking right now to get it loose. Here's a couple of the cylinder. Any discoloration you see is just that. I can't feel any roughness in the bore. Actually, I see a whole lot of cross hatching from the original factory finish. Bear in mind this thing is piston ported but the carb mounts to the crankcase.

Intake:

Exhaust:

Engine bearings are standard 6203 and I was able to match the seals to a CR number. I'm going to try something for the rod big-end needles--since I can't get loose needles, I ordered a bearing that should have the right diameter rollers. I'll cut that bearing apart and try to use the rollers in this rod.

I've already ordered all the bearings I'll need and even picked up the paint for this thing. It needs to get to a sandblast cabinet badly.

Chris B.

If you can find it, there are detailed specs. on bearings. i.e. # of balls & dia. or # of rollers w/dia. x length.

If you can find it, there are detailed specs. on bearings. i.e. # of balls & dia. or # of rollers w/dia. x length.