Being very careful with the layout of where the ring ends are located in the cylinder is the first step I do, then I lay out the outer edges of the piston skirts, both intake and exhaust sides. Next I determine where I want to locate the upper transfers to, like widening them, extending them toward the intake side and where the upper top limits are for each different port job. I would need to know the squish before setting the upper trans height/degrees ATDC. When everything has been layid out then the grinding can begin.

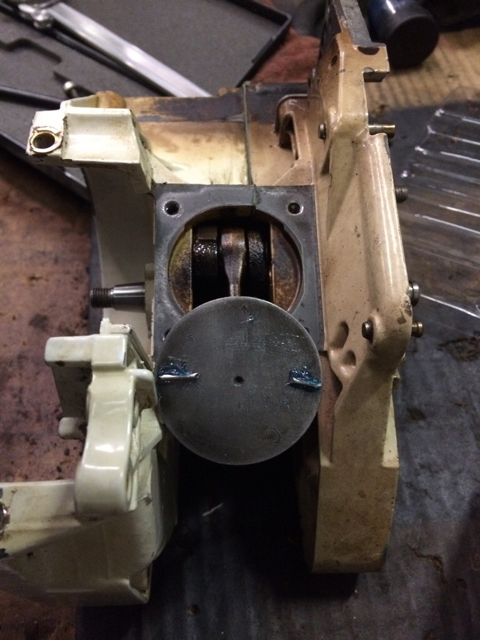

I have been asked many times how to locate the exact spot the piston is located in a cylinder once the cylinder is off the saw. The easiest means is to mark the exhaust port opening on the actual piston before the cylinder is unbolted. Use a very sharp lead pencil and then with the muffler removed trace the outline of the exhaust port onto the piston when it is near TDC. Once the cylinder is removed and the piston is freed from the con rod it can then be put back in the cylinder to set the piston back up to where the tracing matches the exhaust port, I find leaving at least one ring in place on the piston helps keep it in place while then marking the edges of the piston skirts onto the cylinder walls.

I have been asked many times how to locate the exact spot the piston is located in a cylinder once the cylinder is off the saw. The easiest means is to mark the exhaust port opening on the actual piston before the cylinder is unbolted. Use a very sharp lead pencil and then with the muffler removed trace the outline of the exhaust port onto the piston when it is near TDC. Once the cylinder is removed and the piston is freed from the con rod it can then be put back in the cylinder to set the piston back up to where the tracing matches the exhaust port, I find leaving at least one ring in place on the piston helps keep it in place while then marking the edges of the piston skirts onto the cylinder walls.