I am wondering IF there was a way to do a head count how many guys are sitting on the screen eavesdropping in on this thread...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stihl 024 New project

- Thread starter Tpagel

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

ME as # 1 to admit eavesdropping.

13TreeWorks

ArboristSite Operative

Well I participated a while back so count me out of the perverted peeping Tom ball gazer lurkabouts ........ Wow its different on this side of the fence ....

Jesse

Jesse

Tpagel

ArboristSite Operative

Derailing my own thread

Made some big slabs for a bench top

And park benches

Back to play with the 024/026 tomorrow

Sent from my iPhone using Tapatalk

Tpagel

ArboristSite Operative

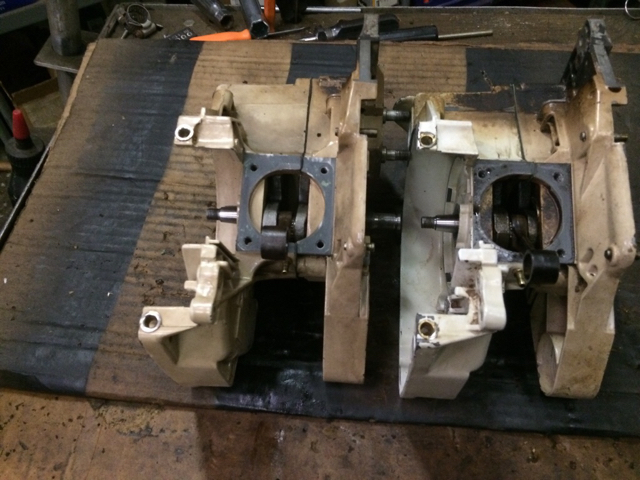

024 case with 026 crank on the left

026 with 026 crank on right

I will split the 024 and pull the 026 crank in search of 024 crank.

As pointed out to me in this thread the angle of throw is different and will not work.

I think you can see the difference in cases from the pics

Sent from my iPhone using Tapatalk

Tpagel

ArboristSite Operative

I traced my port on the piston after I ground them

Maybe the intake is ok?

The exhaust is very close to the full width of the skirt

Trash or not?

Sent from my iPhone using Tapatalk

13TreeWorks

ArboristSite Operative

Ok I'm not trying to hyjack your thread but I just ebayed me a 260 the piston was garbage but the jug had a few small scratches so I tried the miratic acid thing .... Mehh ide rather buff the transfer out like mastermind recommended in a vid ..... So with the transfer cleaned up and a borderline jug in hand I decided it was as good as any to grind on I just opened things up and cleaned up the trashy castings especially the upper transfers mine had almost 1/16 inch ridge of flashing on the top Anywho check out my port-holes ....... Yeah I had to say it

Jesse

Jesse

drf255

BAD CAD

Nice clean work.

Tpagel

ArboristSite Operative

Ok I'm not trying to hyjack your thread but I just ebayed me a 260 the piston was garbage but the jug had a few small scratches so I tried the miratic acid thing .... Mehh ide rather buff the transfer out like mastermind recommended in a vid ..... So with the transfer cleaned up and a borderline jug in hand I decided it was as good as any to grind on I just opened things up and cleaned up the trashy castings especially the upper transfers mine had almost 1/16 inch ridge of flashing on the top Anywho check out my port-holes ....... Yeah I had to say it

View attachment 472126View attachment 472129View attachment 472131View attachment 472132

Jesse

Looks how I would have liked mine to look

What did you use on the transfers?

(Tool and bit)

The lowers look huge I bet it is going to move some charge.

Sent from my iPhone using Tapatalk

Tpagel

ArboristSite Operative

All I did today was measure the cylinder out and advance the timing today but I got a box of parts waiting at the shop

Should have cabers now

Sent from my iPhone using Tapatalk

Should have cabers now

Sent from my iPhone using Tapatalk

drf255

BAD CAD

You don't always want big. Velocity suffers. Case volume goes up and primary compression drops.Looks how I would have liked mine to look

What did you use on the transfers?

(Tool and bit)

The lowers look huge I bet it is going to move some charge.

Sent from my iPhone using Tapatalk

Plus, the crank throws block the bottom of the transfers. Most guysjust blend the lower Lip to prevent fuel puddling.

You don't always want big. Velocity suffers. Case volume goes up and primary compression drops.

Plus, the crank throws block the bottom of the transfers. Most guysjust blend the lower Lip to prevent fuel puddling.

Exactly, too big!

czar800

ArboristSite Guru

drf255

BAD CAD

Looks OK Travis.

I traced my port on the piston after I ground them

Maybe the intake is ok?

The exhaust is very close to the full width of the skirt

Trash or not?

Sent from my iPhone using Tapatalk

It's hard to tell by your pics, but on the intake there appears to be a good amount on space for the ring gap to ride on.

The exhaust looks OK and you have a nice arch in the roof.

13TreeWorks

ArboristSite Operative

I do scroll saw ornaments every year and just sanding them with a dremel seems to burn them up maybe I have the worst luck ever with dremels or they suck and nobody else will admit it ..... This year I bought a harborfreight flex shaft the one that hangs from a hook I have no faith in harborfreight stuff but this actually did ok way better than any dremel I've ever had..... And I can rebuild it if the bearings give out in the hand piece ..... I used a 1/8 dremel carbide grout removal bit and a 5/16 ball burr ..... A homemade split mandrel for Emery cloth those scotch bright buffs and a polishing buff all standard dremel bits except the split mandrill that made from a nail I like the grout tool best. it let me keep my cuts nice and flat and had the length to reach places the other bits couldn't get the ball burr was better for corners .... Oh and a thin flat grinding wheel for the upper transfers I reached down the side of the jug and used the side of the wheel to clean up the flashing on the top edge of the port ..... I need to find a tool that dose a nice bevel on the ports then I'll be able to put it back together ...... I'm going to delete the base gasket and see where that leaves me ..... My goal wasent to make a monster my goal is only to clean it up and make it run happy im looking for cooler temps and longevity .... This is going to be a work saw ... I do tree removals and this saw will see the brunt of the work not a cookie cutting shelf queenLooks how I would have liked mine to look

What did you use on the transfers?

(Tool and bit)

The lowers look huge I bet it is going to move some charge.

Sent from my iPhone using Tapatalk

Jesse

13TreeWorks

ArboristSite Operative

Ok so not to hyjack the thread but I got the 260 back together today ran it for a little bit but it was getting dark ... I tuned it by ear kept it a little rich for now .... I have nothing to compare it to because the top end was trashed when I got it however it starts good runs nice and smooth and it holds rpm in the cut decent but if you fat hand it and drop the rpm below its happy spot you almost have to stop the cut to get it back where it wants to be Its not stumbling off idle or anything goofey I'm happy with where it at

Jesse

Jesse

13TreeWorks

ArboristSite Operative

I never cut the squish to raise the compression like i wanted to I guess that can be a project for another day

Jesse

Jesse

Tpagel

ArboristSite Operative

Mine is waiting on a fuel line and filter before I can get it going again. Doing carb tonight.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

glock37

Addicted to ArboristSite

View attachment 468394 here is what i made and use its heavy but works in all the saws i work on from the 024 to the 064 i have less than 20 bucks in it because i used a steering wheel puller for the bolt and threaded bracket

Why use them just use heat and soft faced hammer heat is your friend

Sent from my iPhone using Tapatalk

Tpagel

ArboristSite Operative

Just got it together can't get it into wood today but it sounds mean piss revving

One ring on my first go at porting a 026 P/C.

Carb needs fine tuning but I need some wood and a tach.

Sent from my iPhone using Tapatalk

Similar threads

- Replies

- 10

- Views

- 484

- Replies

- 27

- Views

- 3K