mikeb1079

ArboristSite Operative

well here it is, i'm finally finished (pretty much :msp_wink with my home built bandsaw mill. gonna call it the "benz-o-matic", benz being the first 4 letters of my last name. i just thought it sounded old timey. :msp_smile:

with my home built bandsaw mill. gonna call it the "benz-o-matic", benz being the first 4 letters of my last name. i just thought it sounded old timey. :msp_smile:

i originally was inspired by gene's bandsaw mill where he used trailer tires. i started down this route but then found some used steel bandsaw wheels which were 25 1/2" diameter. so i had to adapt the design to accomodate those, tho if i had to do it again i would just order 19" wheels from linn lumber. the ones i got used are a bit out of true, plus they're so huge that i had to make the mill wider than it needs to be...

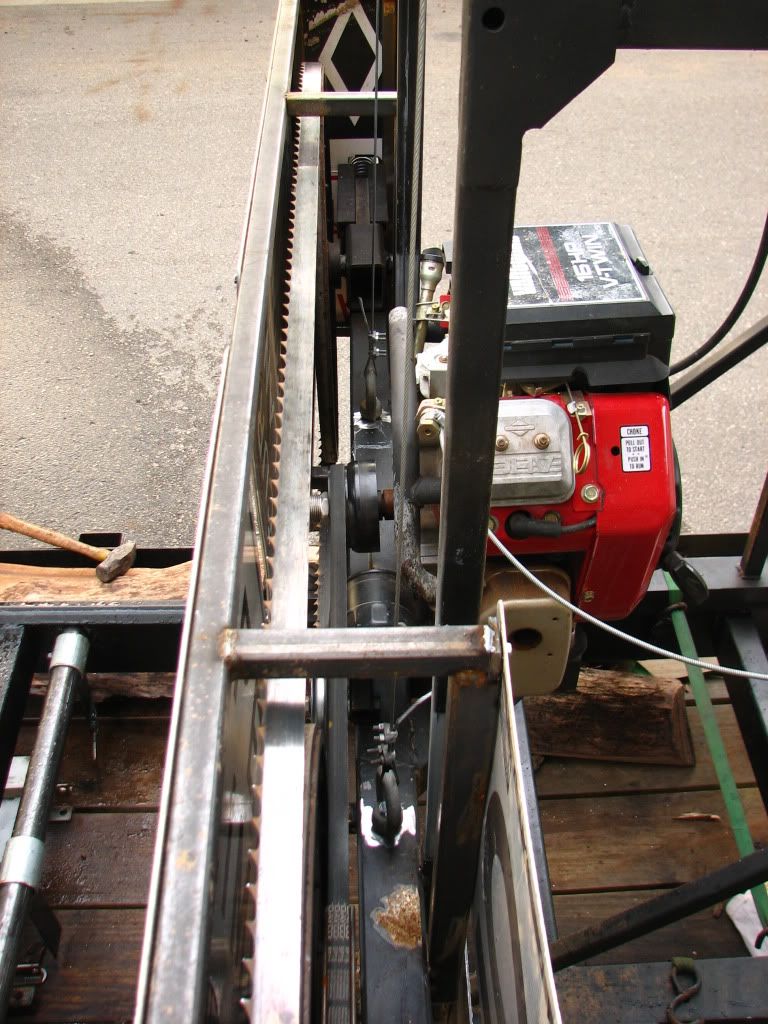

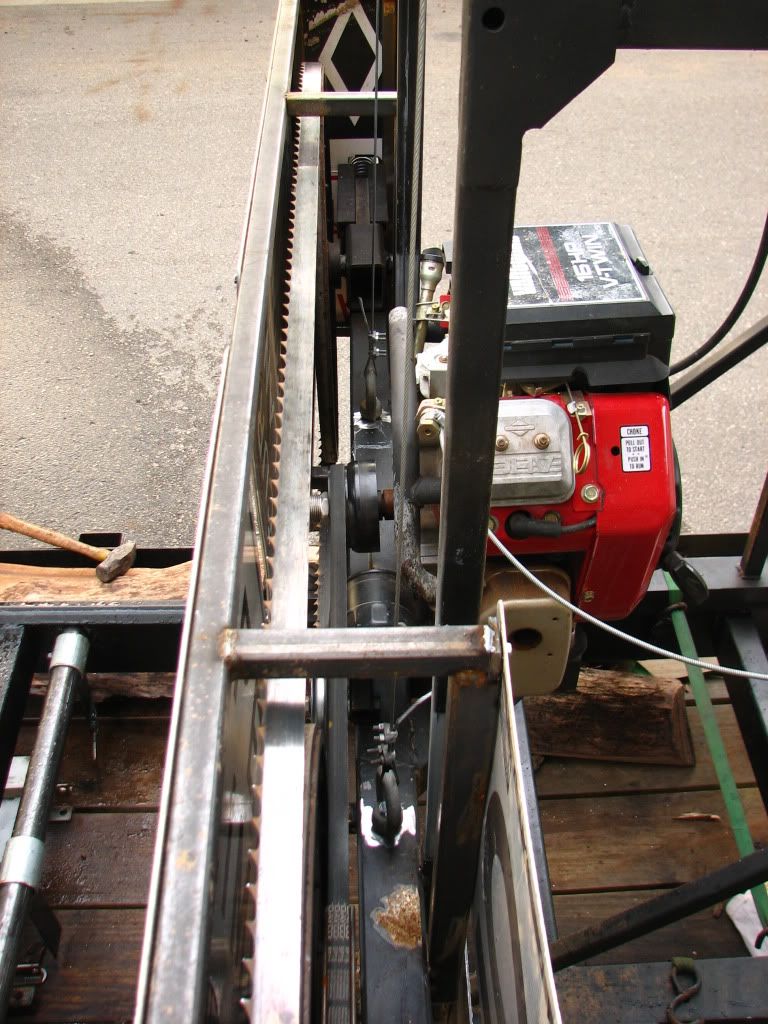

pretty straight forward machine, centrifugal clutch sits on the shaft of a 16 hp briggs to 14" driven pulley on 1" jackshaft mounted on two pillowblocks. it's kinda hard to see in this pic but you get the idea. the whole works moves up and down on 1 1/4" tube that slides over 1" tube, which is suspended over 2 pulleys to the hand crank winch in the upper rear.

found a cheap lawnmower idler control that ramps up the engine speed thus engaging the clutch. this works really well. i'm still having some belt slippage issues and will redesign the tensioner. otherwise the mill works really well. it'll handle a 24" by 12 1/2' log, and i mounted it to the trailer so that i could be portable. some interesting differences on csm vs bsm that i've noticed thus far:

1. bsm cuts smoother and faster with less kerf loss.

2. blade tension and sharpness are critical for bsm.

3. with the bsm i need to be way fussier about cutting thru bark. i've noticed that the fancy mills all use a debarker. this is for good reason. if your logs aren't clean or better yet debarked, your band will not last very long at all. i never really noticed this as much with a csm.

4. while the bsm is faster, it's still a ton of work. if i ever intended to make any money sawing, i'd go full hydraulic without a doubt!

5. you still need a csm for the big logs, either to break em down for the bsm or for those wide slabs we all like. :msp_biggrin:

here's the bearing guide assembly, it slides in and out to adjust to width of log.

and some walnut that i cut with it...

all in all i believe i have about $1200 into it (excluding trailer, and motor, and bands), which aint bad. if anyone is interested and considering doing this i can give you a price breakdown. otherwise enjoy the pics!

i originally was inspired by gene's bandsaw mill where he used trailer tires. i started down this route but then found some used steel bandsaw wheels which were 25 1/2" diameter. so i had to adapt the design to accomodate those, tho if i had to do it again i would just order 19" wheels from linn lumber. the ones i got used are a bit out of true, plus they're so huge that i had to make the mill wider than it needs to be...

pretty straight forward machine, centrifugal clutch sits on the shaft of a 16 hp briggs to 14" driven pulley on 1" jackshaft mounted on two pillowblocks. it's kinda hard to see in this pic but you get the idea. the whole works moves up and down on 1 1/4" tube that slides over 1" tube, which is suspended over 2 pulleys to the hand crank winch in the upper rear.

found a cheap lawnmower idler control that ramps up the engine speed thus engaging the clutch. this works really well. i'm still having some belt slippage issues and will redesign the tensioner. otherwise the mill works really well. it'll handle a 24" by 12 1/2' log, and i mounted it to the trailer so that i could be portable. some interesting differences on csm vs bsm that i've noticed thus far:

1. bsm cuts smoother and faster with less kerf loss.

2. blade tension and sharpness are critical for bsm.

3. with the bsm i need to be way fussier about cutting thru bark. i've noticed that the fancy mills all use a debarker. this is for good reason. if your logs aren't clean or better yet debarked, your band will not last very long at all. i never really noticed this as much with a csm.

4. while the bsm is faster, it's still a ton of work. if i ever intended to make any money sawing, i'd go full hydraulic without a doubt!

5. you still need a csm for the big logs, either to break em down for the bsm or for those wide slabs we all like. :msp_biggrin:

here's the bearing guide assembly, it slides in and out to adjust to width of log.

and some walnut that i cut with it...

all in all i believe i have about $1200 into it (excluding trailer, and motor, and bands), which aint bad. if anyone is interested and considering doing this i can give you a price breakdown. otherwise enjoy the pics!