rbtree

Addicted to ArboristSite

Better later than never:

Thanks to Andy, we were called to remove 80 feet of a hemlock which failed onto a multi-million dollar home, from the snow load.

This is at Lake Tuck, near Duvall, where there was 2 feet of snow on the ground or more, from 6 different snow events.

The roads are barely passable, even with 4wd, even after their private gated community has been plowed twice. So, a crane was out of the question.

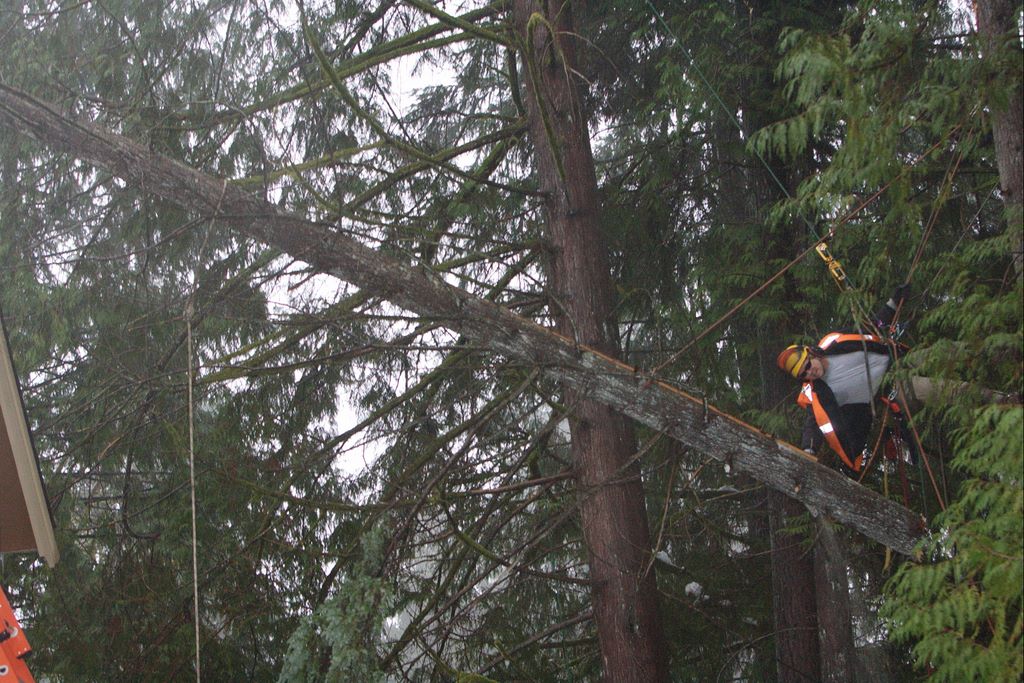

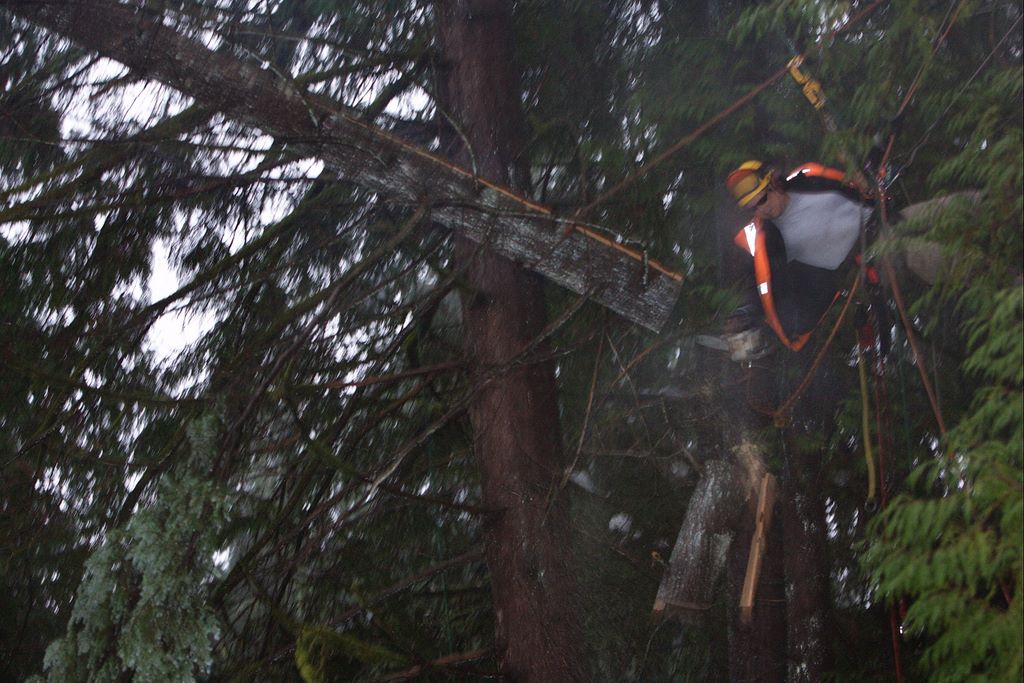

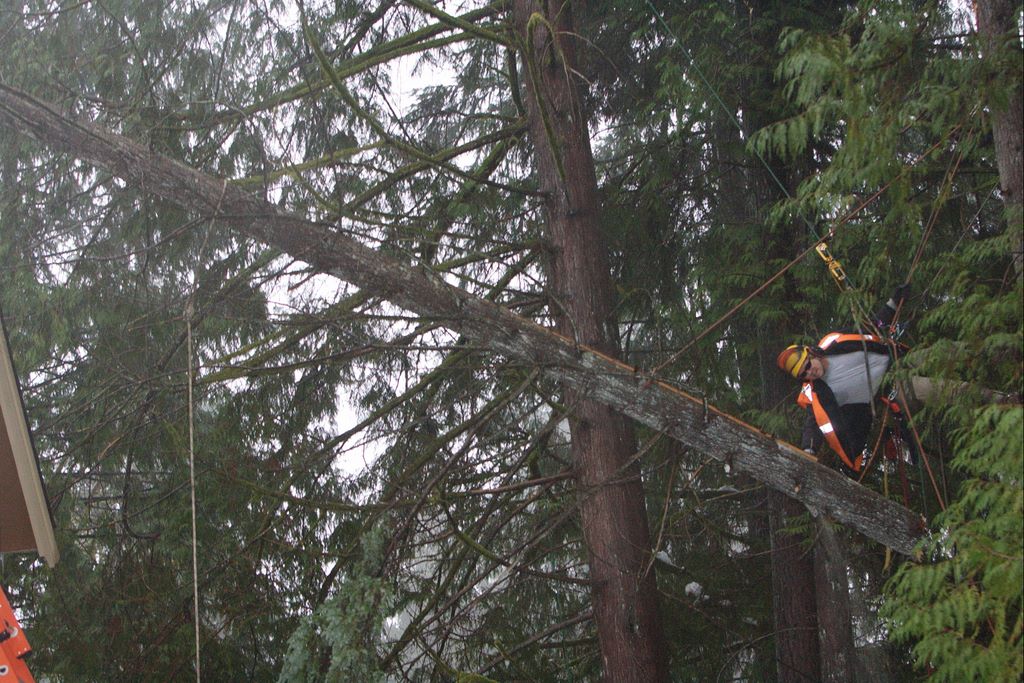

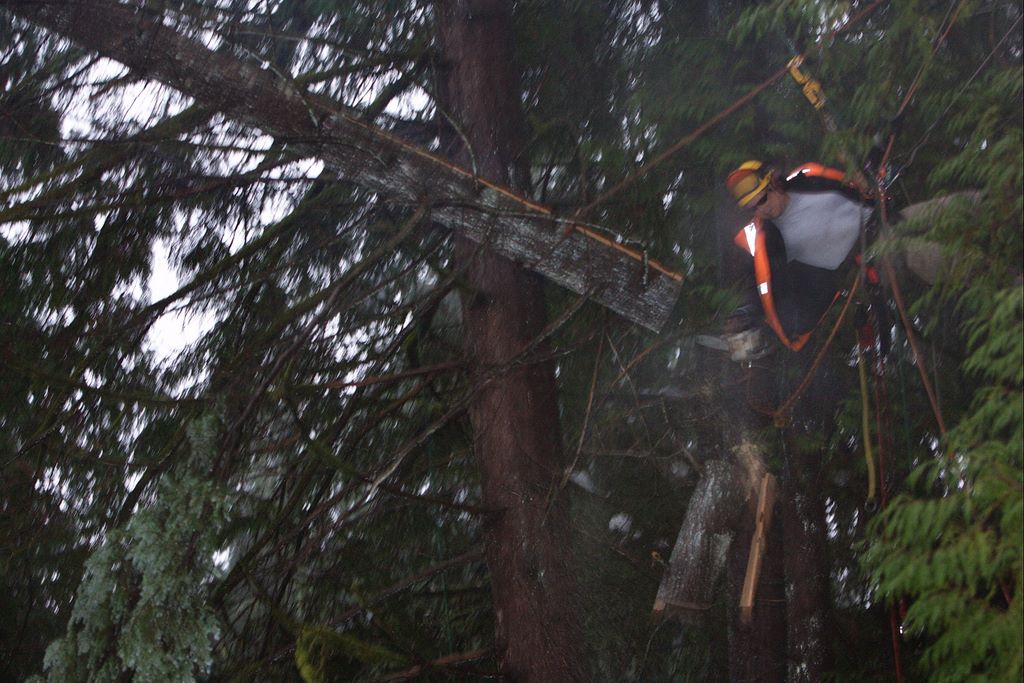

We arrived late today. Mike Oxman climbed the snag, set a block, and cut off a couple pieces. The line was fixed to a porta wrap. I had set a line in a well positioned cedar. Mike jugged up it, and set another block, which was set to be retrievable from the ground. Our static line was rigged, and I tied it to the 25 foot portion of the tree overhanging the deck. We tensioned it with each rope, and I cut it free. They lowered it down neatly.

I had accessed the roof via a 32 foot ladder, tossed my lifeline over to the tree and pulled myself to it, via a 45 degree steep section of roof. Then, I'd gone across the main roof and tied a mid line to the tree, and thrown it to the ground opposite the side we'd be attempting to lift the tree. It was tied back to keep the tree from swinging sideways too fast when we lifted it.

Mike had been concerned that the tree on the roof might move a bit, so he had tossed my another line to tie past where we cut the overhanging section off. He'd run it around the cedar at 30 feet. Turns out the tree stayed put, so we pulled that out and retied it closer to the top, and tossed it over the roof on the same side as we'd be lifting, in case we needed to help the tree swing clear of the house. I got the static line back and tied it 25 feet from the tip, and tied the butt line back to the 30 foot snag. Then I came down, and we tried to lift the entire remaining 45-50 feet off. No luck, the line angles were too extreme, and the tree is weighted down with the snow on it, plus a branch or two could be stuck in the roof.

So, we'll go back tomorrow. There's a perfectly placed hemlock which we'll set a block in and another static line, attach that line to the tip, and remove the first static line and tie it to the butt, where it will be well placed to lift the butt up. We'll get rid of the line and block at 30 feet in the snag. We'll attach the Hobbs lifting/lowering device to the hemlock so we can lift each line in unison. The back line will still allow us to control the sideways movement. It should hang clear of the roof and be able to be neatly lowered to the ground.

It may be raining tomorrow, but I hope to be able to be up the snag, taking pics and video of the operation. I'll get Andy to replace me while I'm filming.

Thanks to Andy, we were called to remove 80 feet of a hemlock which failed onto a multi-million dollar home, from the snow load.

This is at Lake Tuck, near Duvall, where there was 2 feet of snow on the ground or more, from 6 different snow events.

The roads are barely passable, even with 4wd, even after their private gated community has been plowed twice. So, a crane was out of the question.

We arrived late today. Mike Oxman climbed the snag, set a block, and cut off a couple pieces. The line was fixed to a porta wrap. I had set a line in a well positioned cedar. Mike jugged up it, and set another block, which was set to be retrievable from the ground. Our static line was rigged, and I tied it to the 25 foot portion of the tree overhanging the deck. We tensioned it with each rope, and I cut it free. They lowered it down neatly.

I had accessed the roof via a 32 foot ladder, tossed my lifeline over to the tree and pulled myself to it, via a 45 degree steep section of roof. Then, I'd gone across the main roof and tied a mid line to the tree, and thrown it to the ground opposite the side we'd be attempting to lift the tree. It was tied back to keep the tree from swinging sideways too fast when we lifted it.

Mike had been concerned that the tree on the roof might move a bit, so he had tossed my another line to tie past where we cut the overhanging section off. He'd run it around the cedar at 30 feet. Turns out the tree stayed put, so we pulled that out and retied it closer to the top, and tossed it over the roof on the same side as we'd be lifting, in case we needed to help the tree swing clear of the house. I got the static line back and tied it 25 feet from the tip, and tied the butt line back to the 30 foot snag. Then I came down, and we tried to lift the entire remaining 45-50 feet off. No luck, the line angles were too extreme, and the tree is weighted down with the snow on it, plus a branch or two could be stuck in the roof.

So, we'll go back tomorrow. There's a perfectly placed hemlock which we'll set a block in and another static line, attach that line to the tip, and remove the first static line and tie it to the butt, where it will be well placed to lift the butt up. We'll get rid of the line and block at 30 feet in the snag. We'll attach the Hobbs lifting/lowering device to the hemlock so we can lift each line in unison. The back line will still allow us to control the sideways movement. It should hang clear of the roof and be able to be neatly lowered to the ground.

It may be raining tomorrow, but I hope to be able to be up the snag, taking pics and video of the operation. I'll get Andy to replace me while I'm filming.

Last edited:

if I was lucky and had a cottonwood near by.

if I was lucky and had a cottonwood near by. The third line(blue) was being held by yourself on the roof? or was that crotched on another tree on the opposite side of the house? so 3 ropes, one man on each.

The third line(blue) was being held by yourself on the roof? or was that crotched on another tree on the opposite side of the house? so 3 ropes, one man on each.