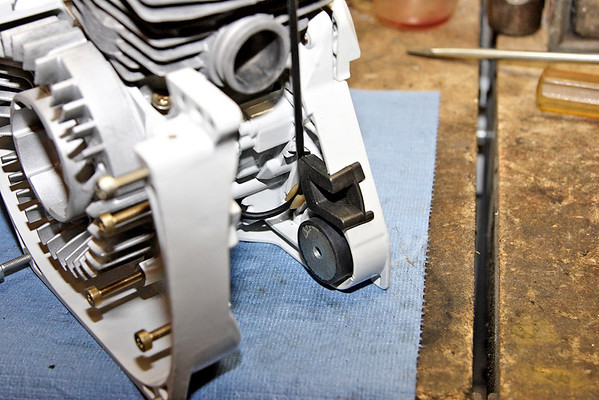

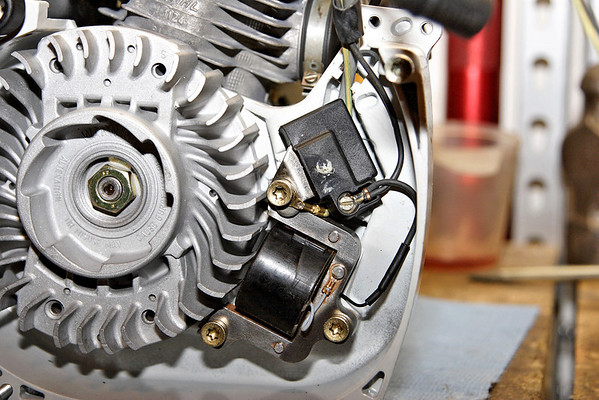

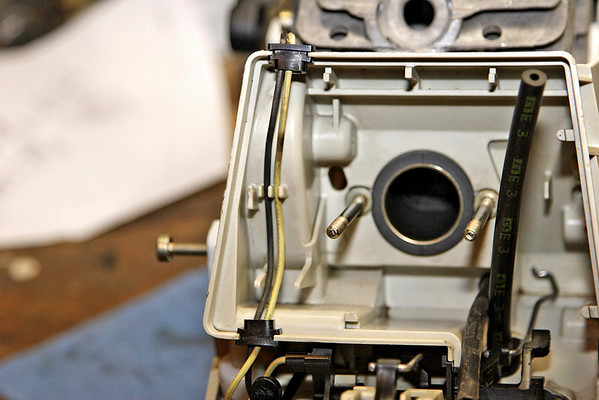

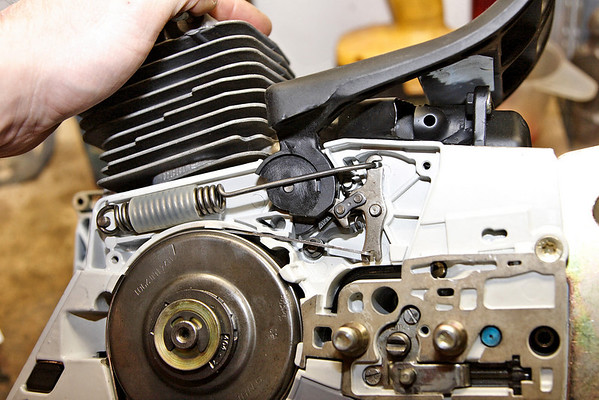

Next I begin installing the rest of the chain brake system.

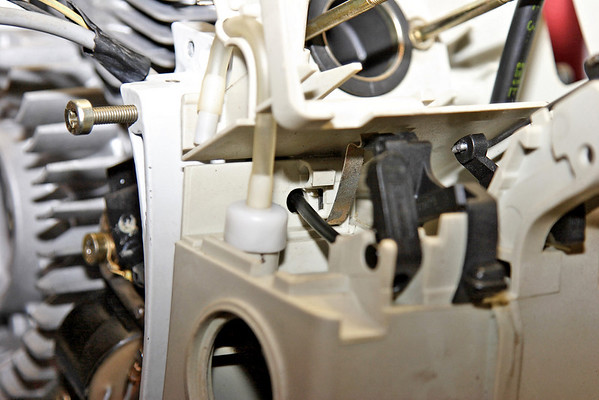

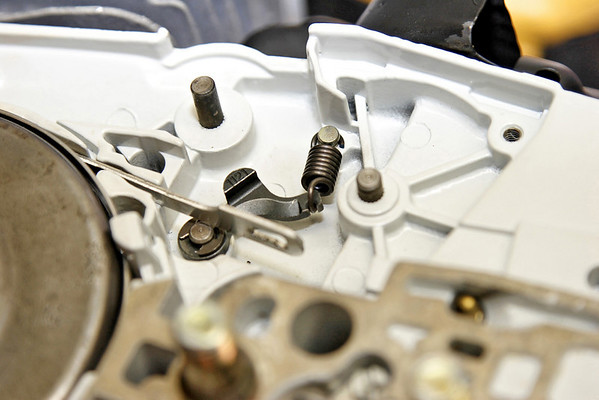

I'm missing a little e-clip on the one arm here. Should have it tomorrow.

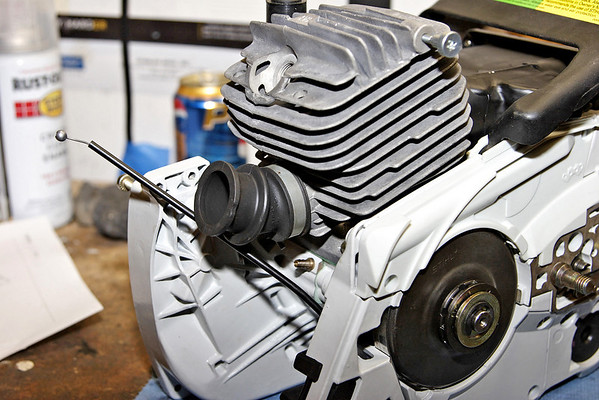

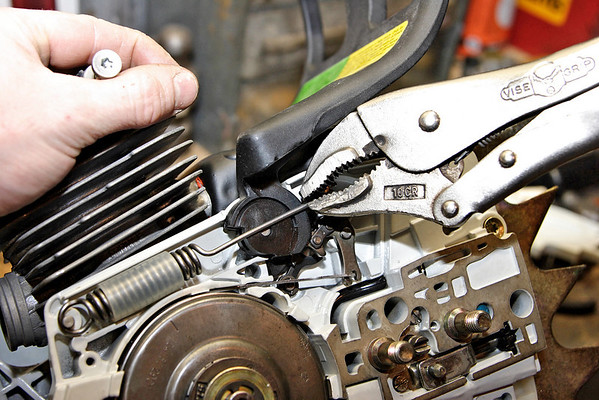

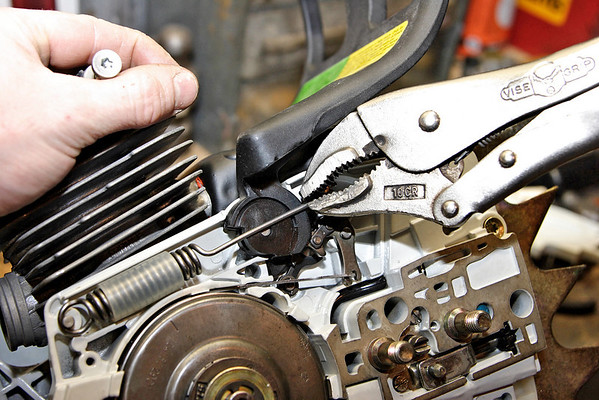

Even with a good sized set of ViseGrips, this is still not easy.

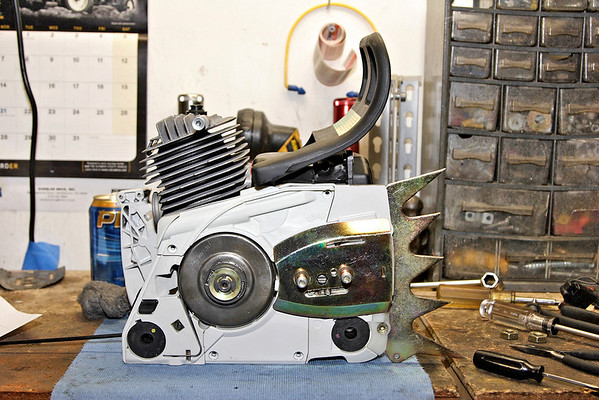

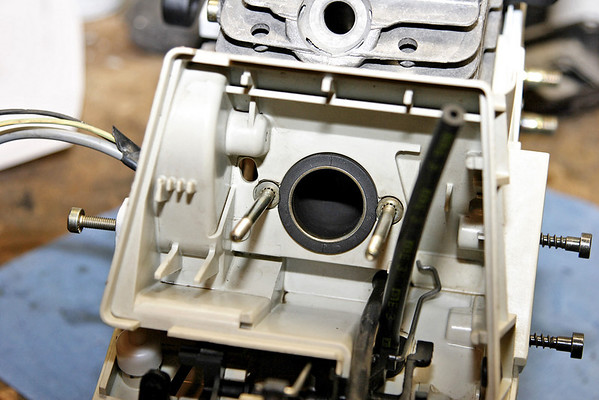

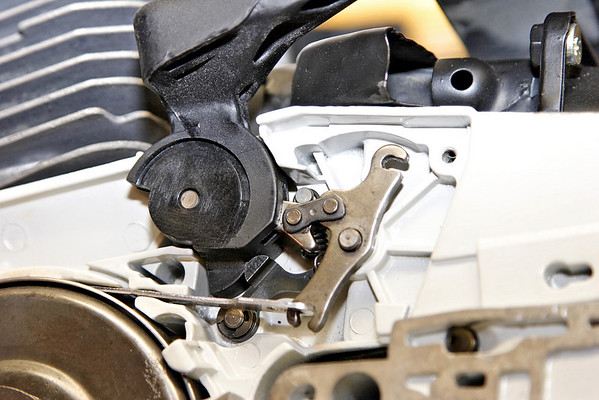

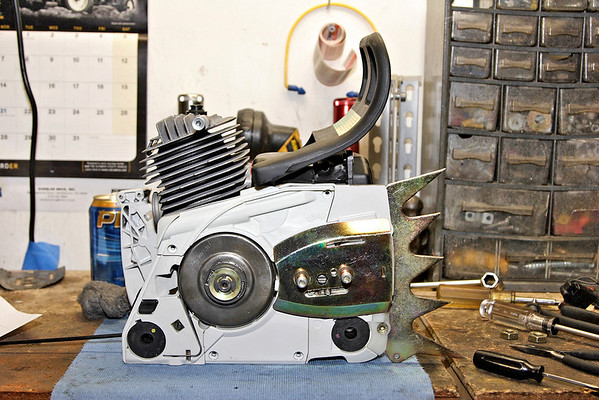

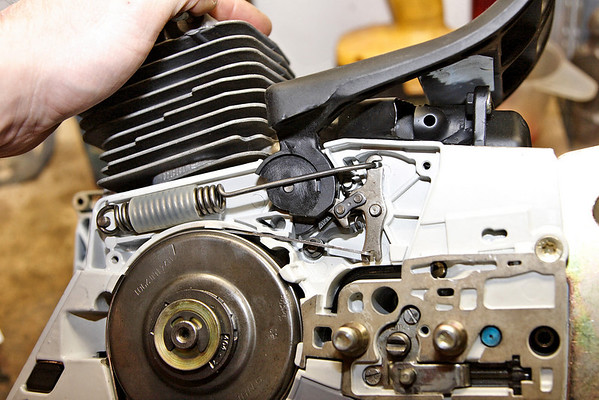

The complete assembly.

Again, I'm missing several cover bolts I hope come in tomorrow.

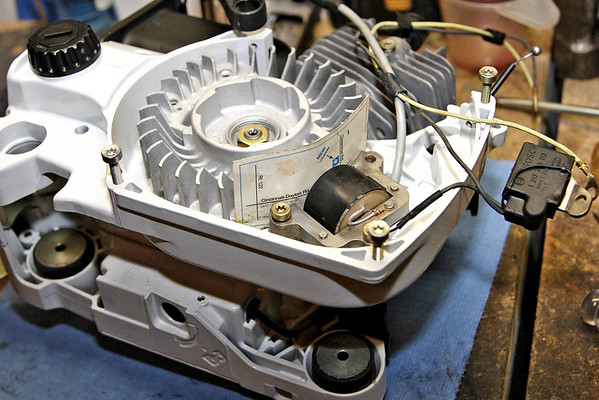

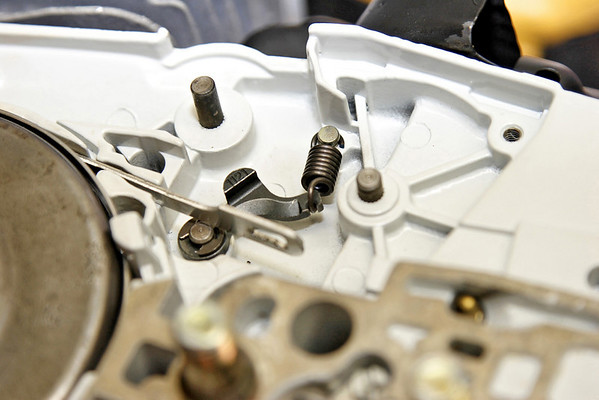

I'm missing a little e-clip on the one arm here. Should have it tomorrow.

Even with a good sized set of ViseGrips, this is still not easy.

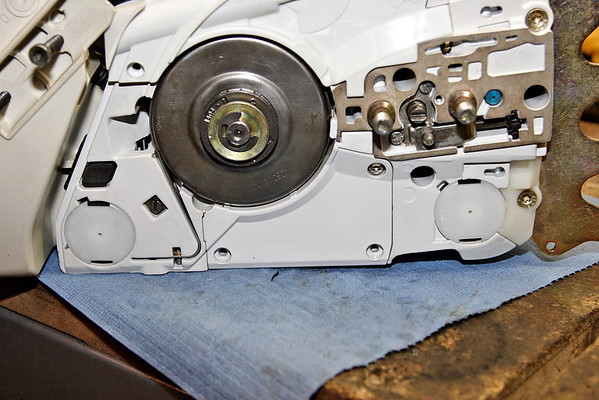

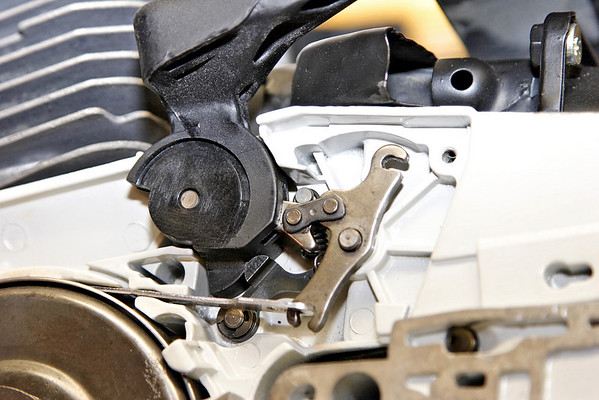

The complete assembly.

Again, I'm missing several cover bolts I hope come in tomorrow.