nnero

ArboristSite Guru

I recently restored my dads 041 and purchased a parts saw mainly for the ignition, rear handle and clutch cover. I have decided to put the parts back together. I have rounded up enough parts to do so. It has poor compression and you can feel the piston drag in the cylinder. I dont know exactly what it will need until I get it apart.

Here are some random parts:

Here is a complete ignition I got for $25:

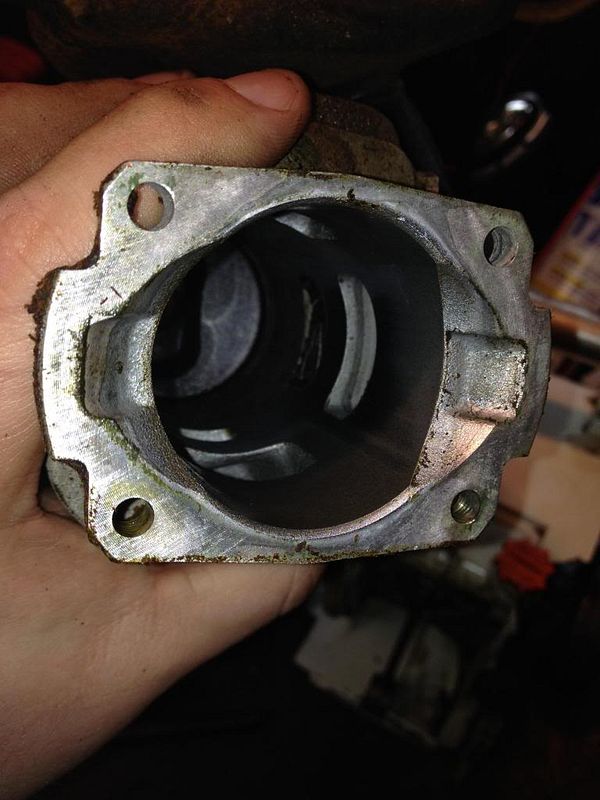

Here are two shots of the powerhead. Its filthy and I am in the process of cleaning it up:

I wont order air filter, new sprocket, bar/chain etc until I find out whats going on inside. I think this will get at least a 20" bar. My MS260 has a 16" and will be used 90% of the time.

This will be my first engine rebuild and should get me through the rest of winter lol. I think it will be fun. I will update periodically with pics, questions and info. Thanks.

Here are some random parts:

Here is a complete ignition I got for $25:

Here are two shots of the powerhead. Its filthy and I am in the process of cleaning it up:

I wont order air filter, new sprocket, bar/chain etc until I find out whats going on inside. I think this will get at least a 20" bar. My MS260 has a 16" and will be used 90% of the time.

This will be my first engine rebuild and should get me through the rest of winter lol. I think it will be fun. I will update periodically with pics, questions and info. Thanks.