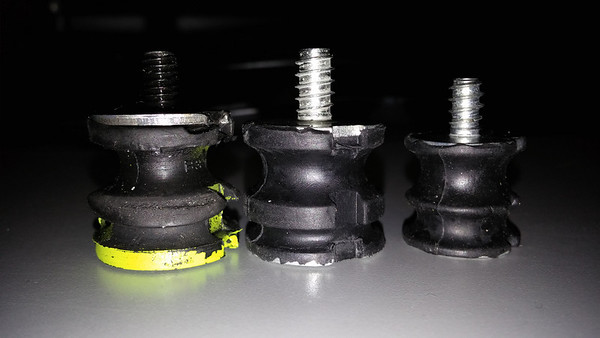

As many of you already know, AV bushings for the 5200 are NLA. I read somewhere that there was a Husky bushing that could be made to work. It was mentioned that it was the "small" one from a "2 series" saw. I ordered these and they were way too small.

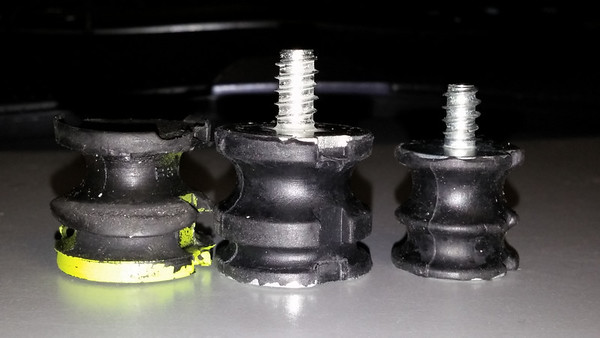

I then ordered the large ones. The AV mount itself is nearly identical. Diameter is the same and length is within 1/16".

The only hurdle to overcome now is that these are made to thread into plastic. I've considered several options. One would be cutting the first few threads of the stud to resemble a self threading sheet metal screw. I've also contemplated trying to replace the stud with a bolt thread into the metal base. Most promising would be if I could dress the coarse threads off the stud and tap to the correct size. Any advice would be appreciated.

Note: The metal base and stud on the original mount is simply setting there unattached.

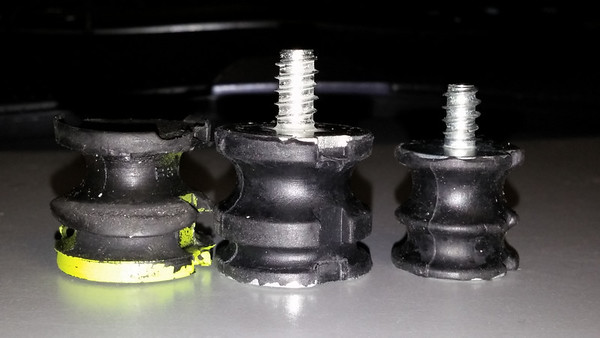

I then ordered the large ones. The AV mount itself is nearly identical. Diameter is the same and length is within 1/16".

The only hurdle to overcome now is that these are made to thread into plastic. I've considered several options. One would be cutting the first few threads of the stud to resemble a self threading sheet metal screw. I've also contemplated trying to replace the stud with a bolt thread into the metal base. Most promising would be if I could dress the coarse threads off the stud and tap to the correct size. Any advice would be appreciated.

Note: The metal base and stud on the original mount is simply setting there unattached.