You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is Anyone Interested In Seeing How I Port A 372XP

- Thread starter Mastermind

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Mastermind

Work Saw Specialist

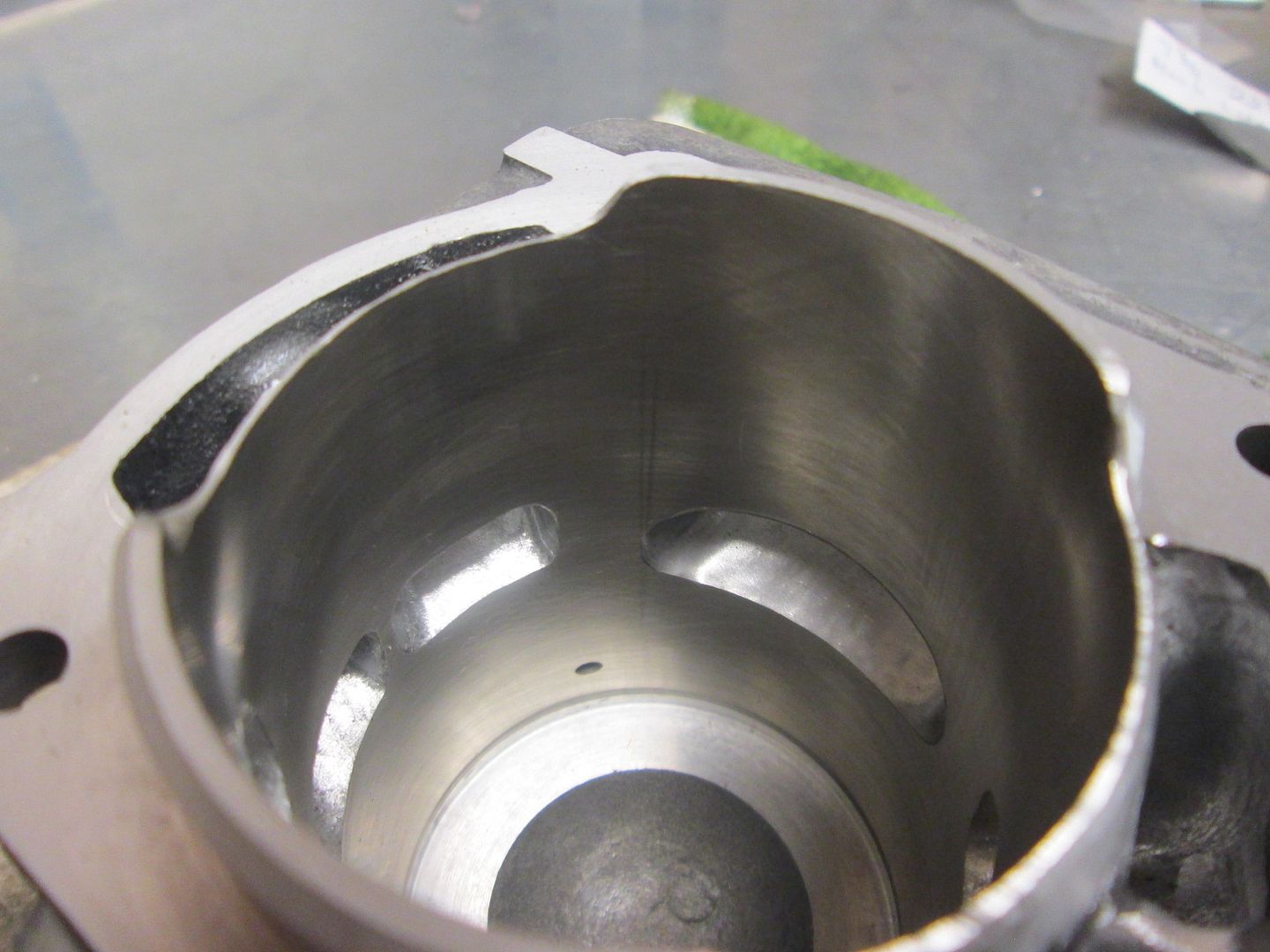

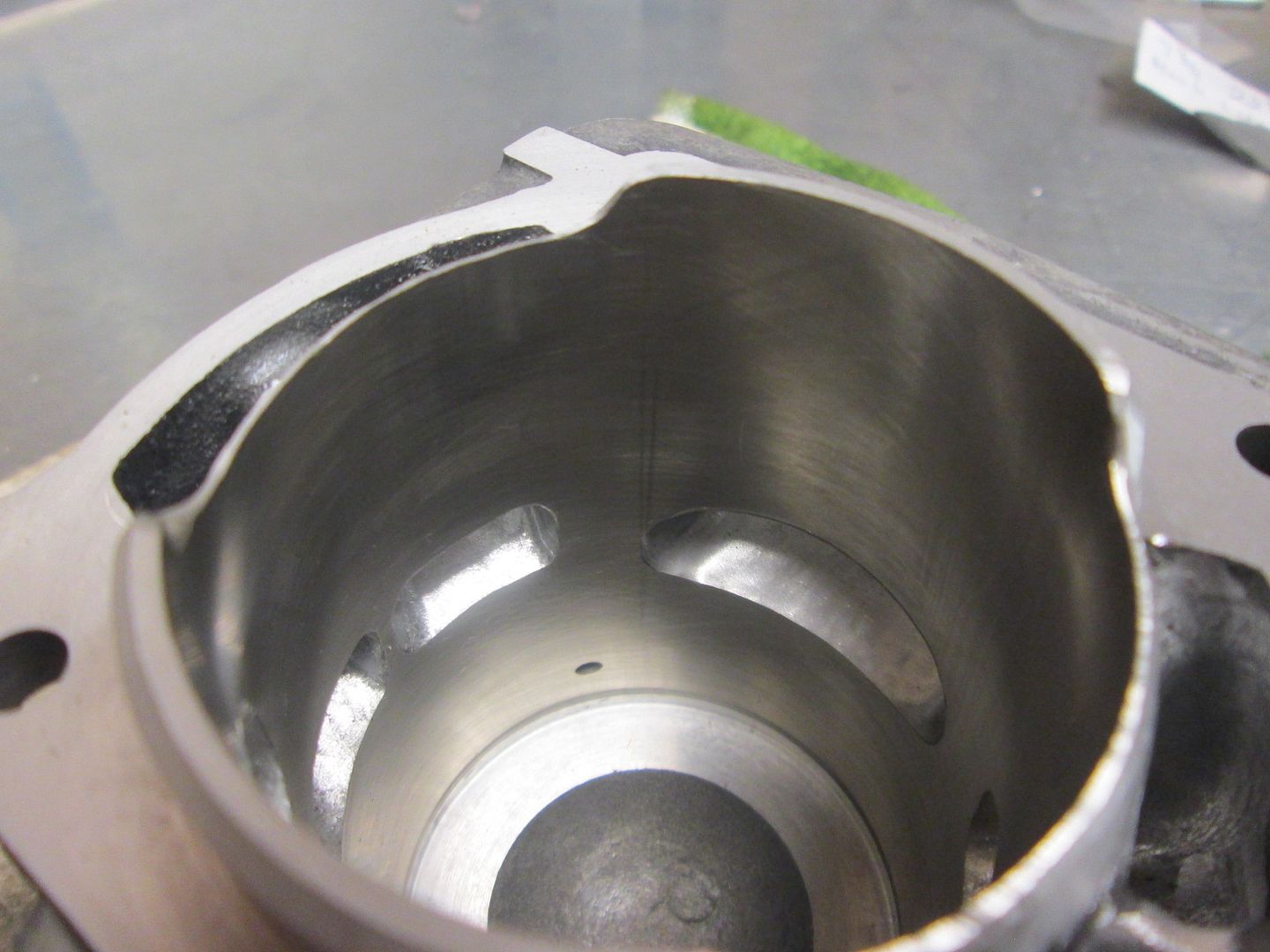

Now the exhaust port is another place that I spend some serious time on the 372. Again....I've tried a bunch of different stuff.......but the exhaust height at 100 - 99 degrees from TDC seems to work reall well on the 372 when it's main propose is to pull a work chain.

There still has to be a bevel and some polish here. I use a 1/4" diameter diamond stone in my RT angle to do the bevel.....and varying grades of Scotchbrite for the polish on the port edges.

There still has to be a bevel and some polish here. I use a 1/4" diameter diamond stone in my RT angle to do the bevel.....and varying grades of Scotchbrite for the polish on the port edges.

ouch

Whats up with the goo in the right-hand jug? Some of that technoplate whatever?

bower4311

ArboristSite Operative

Not yet.

Send me your computer. I'll port it for free.

bower4311

ArboristSite Operative

well for the record,,, here is the one randy did for me,, he did not build it for racing just for work,, I like,, I like:msp_biggrin::msp_biggrin:

before

<iframe width="560" height="315" src="//www.youtube.com/embed/V6TWANjDOzI" frameborder="0" allowfullscreen></iframe>

after

<iframe width="560" height="315" src="//www.youtube.com/embed/10aUUxoPl18" frameborder="0" allowfullscreen></iframe>

hope this helps you randy,, heck free advertising

These videos are awesome played at the same time haha. Good stuff.

Mastermind

Work Saw Specialist

procarbine2k1

Addicted to ArboristSite

I sure don't know everything, and would love the hear opinions, ideas, mild criticism.

You are humble, admit that there is more to learn, and have such a level headed approach to your builds and the way that you present them on AS- I think that is a good part of the reason you are well respected here IMO. I don't ever remember you carrying a "better than thou attitude", or demeaning anyone looking to learn. I feel like I have learned quite a bit from you, just from reading and watching your work intently in these build threads. I think many of us have. I'm not butt kissin' here, but I think there are more than a couple reasons guys here are keeping you working around the clock, and your attitude is probably #1.

You are humble, admit that there is more to learn, and have such a level headed approach to your builds and the way that you present them on AS- I think that is a good part of the reason you are well respected here IMO. I don't ever remember you carrying a "better than thou attitude", or demeaning anyone looking to learn. I feel like I have learned quite a bit from you, just from reading and watching your work intently in these build threads. I think many of us have. I'm not butt kissin' here, but I think there are more than a couple reasons guys here are keeping you working around the clock, and your attitude is probably #1.Mastermind

Work Saw Specialist

The transfers I think are where you can either build a saw that has that WOW factor or one that is just OK.......on the 51.4 mm XPW jug I set them at 122 degrees from TDC for a BD time of 22 degrees.

o8f150

Tree Freak

well for the record,,, here is the one randy did for me,, he did not build it for racing just for work,, I like,, I like:msp_biggrin::msp_biggrin:

before

<iframe width="560" height="315" src="//www.youtube.com/embed/V6TWANjDOzI" frameborder="0" allowfullscreen></iframe>

after

<iframe width="560" height="315" src="//www.youtube.com/embed/10aUUxoPl18" frameborder="0" allowfullscreen></iframe>

hope this helps you randy,, heck free advertising

I forgot to mention,, that is the same big maple log,, there is a big difference in cut speed,,, I get a stiffy everytime I run it

samdweezel05

ArboristSite Guru

Hay Randy, can you do some port work on an aftermarket BB kit on a 660?

o8f150

Tree Freak

These videos are awesome played at the same time haha. Good stuff.

if you liked that,, try this other thread I started,, sounds like a chevy engine with no muffler,,,,,, ooopppssss sorry randy,, I think I hijacked your thread

http://www.arboristsite.com/chainsaw/240212.htm

Mastermind

Work Saw Specialist

On the intake I let the lowering of the cylinder determine the duration. The way I cut the squish and lower the jug I end up at 80 - 82 degrees. I don't do a lot of widening on the intake on this model because I would rather not add any more time/area to the port.

Mastermind

Work Saw Specialist

Hay Randy, can you do some port work on an aftermarket BB kit on a 660?

I've yet to find a BB 660 jug that I like Sam.

I gotta sign off for a bit........be back later.

bryanr2

Addicted to ArboristSite

30 users........ finally something worth reading.

I've yet to find a BB 660 jug that I like Sam.

I gotta sign off for a bit........be back later.

This is something I've been wondering so I'll jump on this hijack. Is porting and aftermarket jug generally not a good idea? I seem to remember reading that somewhere but don't remember where. Is it a waste of time? By the way, repped for a good thread and something worth reading lately.

shoe601

ArboristSite Lurker

Randy I don't know if this is how you did the 375 I bought from you but it sure cuts. It's been so hot I've only got a couple tanks through it but its one hell of a strong saw. Thank You.

Bryan

Bryan

Jimmy in NC

Addicted to ArboristSite

This is something I've been wondering so I'll jump on this hijack. Is porting and aftermarket jug generally not a good idea? I seem to remember reading that somewhere but don't remember where. Is it a waste of time? By the way, repped for a good thread and something worth reading lately.

Depends on the kit. I've got a ported Meteor kit on my 372 done by Randy and its a strong work saw. 24" with an 8 pin all day in hardwood.

Back on topic to see how he chews on cylinders.....

Jimmy

bryanr2

Addicted to ArboristSite

You are humble, admit that there is more to learn, and have such a level headed approach to your builds and the way that you present them on AS- I think that is a good part of the reason you are well respected here IMO. I don't ever remember you carrying a "better than thou attitude", or demeaning anyone looking to learn. I feel like I have learned quite a bit from you, just from reading and watching your work intently in these build threads. I think many of us have. I'm not butt kissin' here, but I think there are more than a couple reasons guys here are keeping you working around the clock, and your attitude is probably #1.

that about sums it up.

Plus he has the coolest username/ sticker.:msp_wink:

Plus he has the coolest username/ sticker.:msp_wink:There's 13.2 grams of chips in that pile.......I figured it would weigh more.

Maybe you should be pricing your port work by the pound. Just sayin.

Similar threads

- Replies

- 8

- Views

- 664