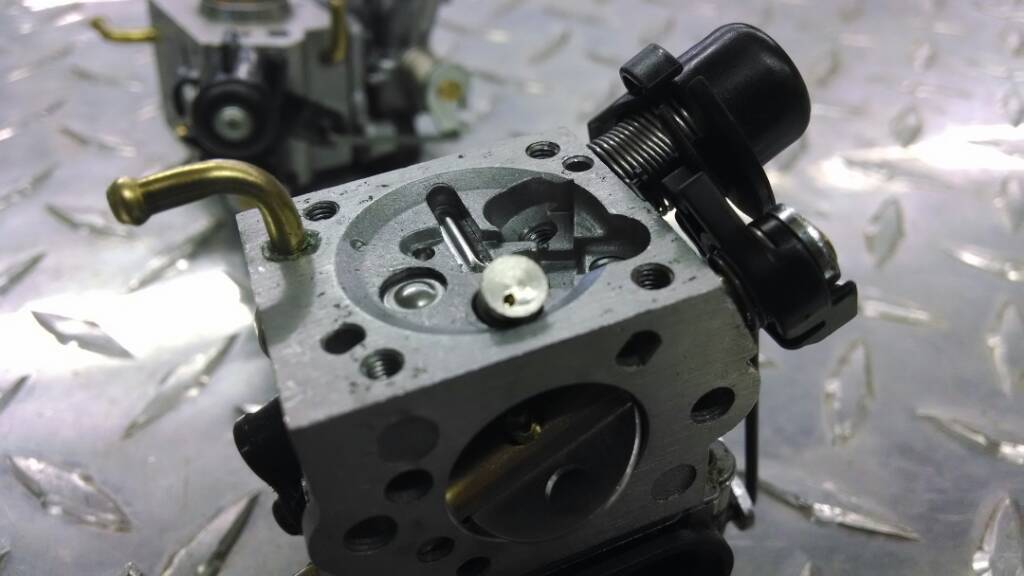

Gentlemen, gentlemen. While we are chasing a solution to this hesitation issue, let's be careful that we don't draw the wrong conclusion. From talking to TK, Terry and a couple others, it seems like everyone is zeroing in on the main nozzle as the culprit here. Someone, tried a nozzle out of an EL44 and the problem went away. So far so good. However, a check of IPL's for the 44, 46, and 47 carbs all show the same part number for the main nozzle. So, concluding that the EL44 is good and the EL46 is bad, would not be correct. Further, a look at the service bulletin announcing the change to the updated carbs reveals the reason for the change, which was the addition of the extra service connector to make it easier to plug it into the diagnostic tool. Also, at this time, the AT module automatically comes with the carb and is no longer available as a separate part. This explains why the 562 and 555 got "different" carbs; EL46 for the 562 and EL47 for the 555. So that and no changes to the IPL suggest that there may be no internal changes to the carb itself.

So what's up with the nozzle, part # 576414201? Not really sure, cause there are still some unanswered questions. And the problem does not affect all saws; just a small number actually. One possibility is that there are simply some bad nozzles out there. Another guess is that Zama could have manufactured some carbs with the wrong nozzle. And it wouldn't be the first time this has happened. When the EBZ8500 first came out, some were blowing up because they got carbs that had the nozzle from the smaller EBZ7500. They would run lean and detonate like heck. Some pistons looked like they had been shot with a .22.

I certainly don't have an answer yet, but let's all be sure of what's going on before drawing any conclusions here. I'll make a call to tech service on Monday and see what I can learn and I'll e-mail a contact in Sweden and see what his thoughts are.

Guess it's back on the "potential purchase" list

Guess it's back on the "potential purchase" list