KG441c

Keith

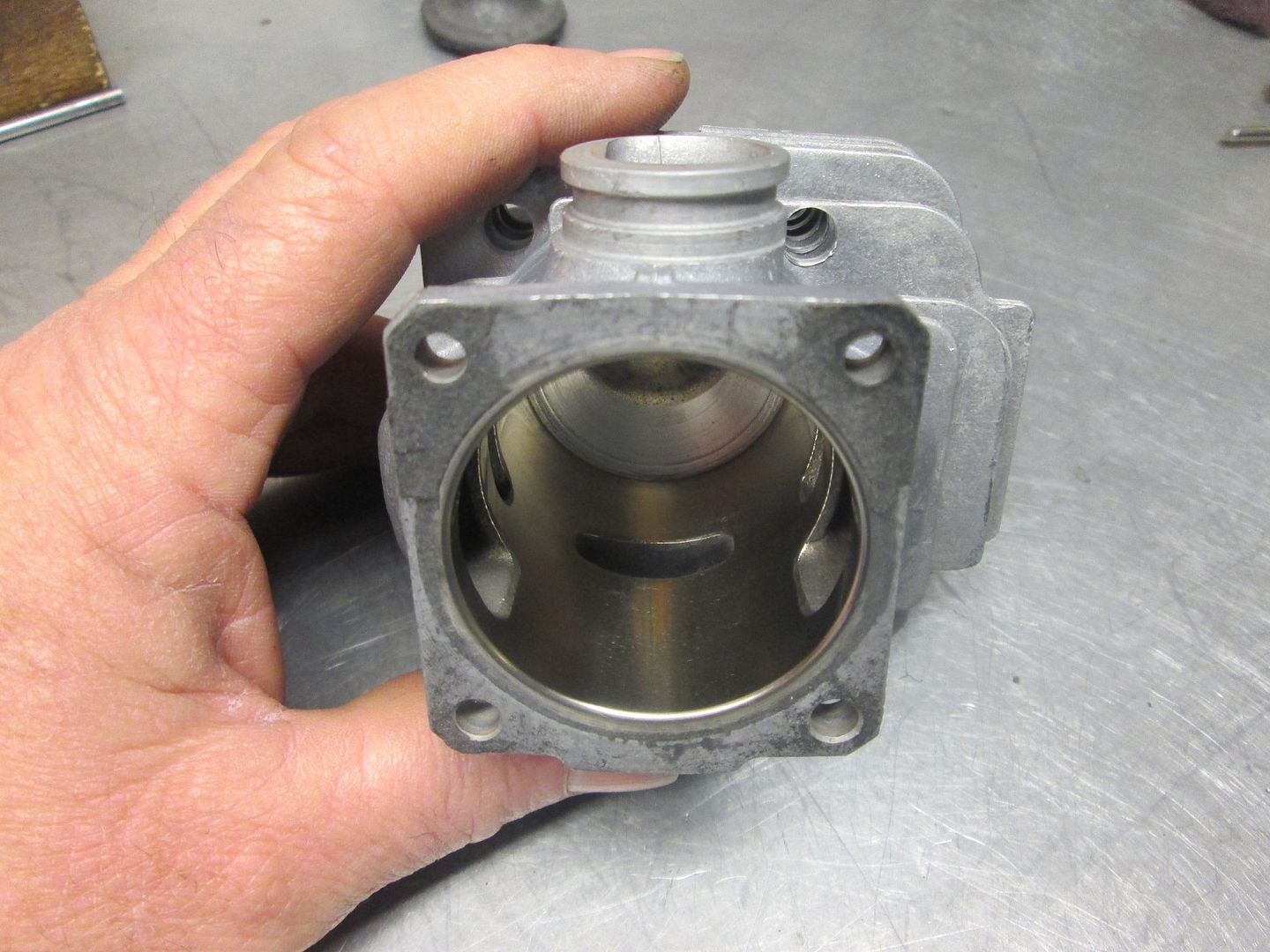

Im not sure! Lol! Im trying to learn myself but I uusually do use a very light oil and just a very mild flex hone after cleaning a cylinder and giving new rings a new fresh surface for a set of rings to seat into. Always has worked for me but im sure scotchbrite is just as good and safer. You can overdo it quick with a flexhone