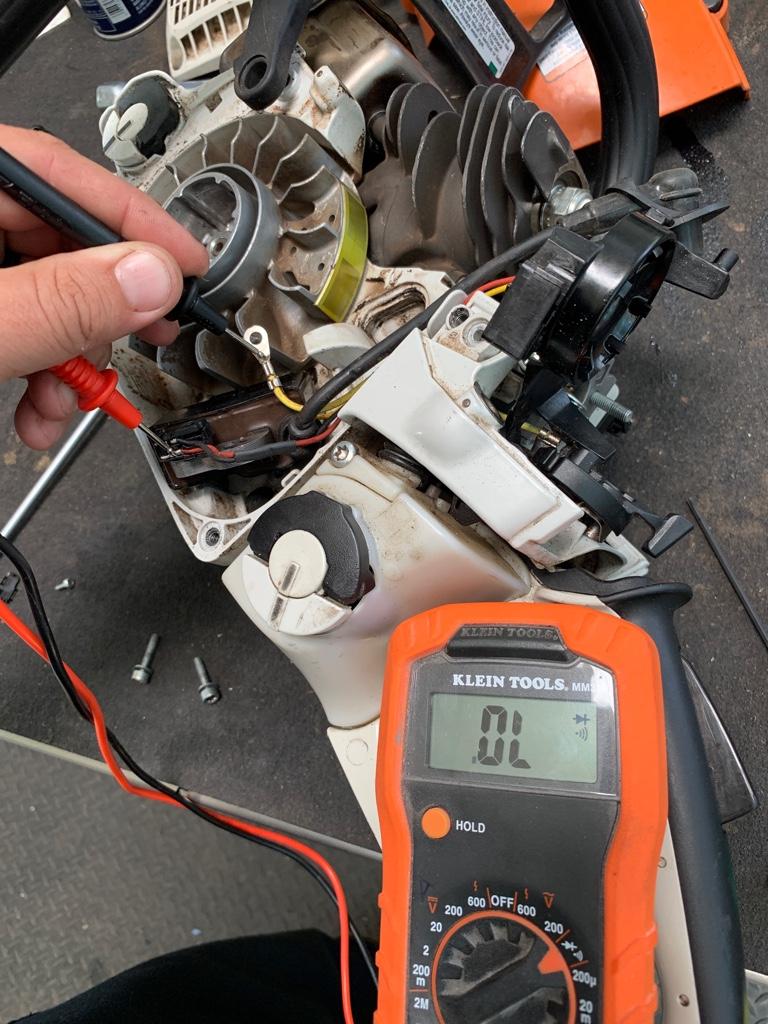

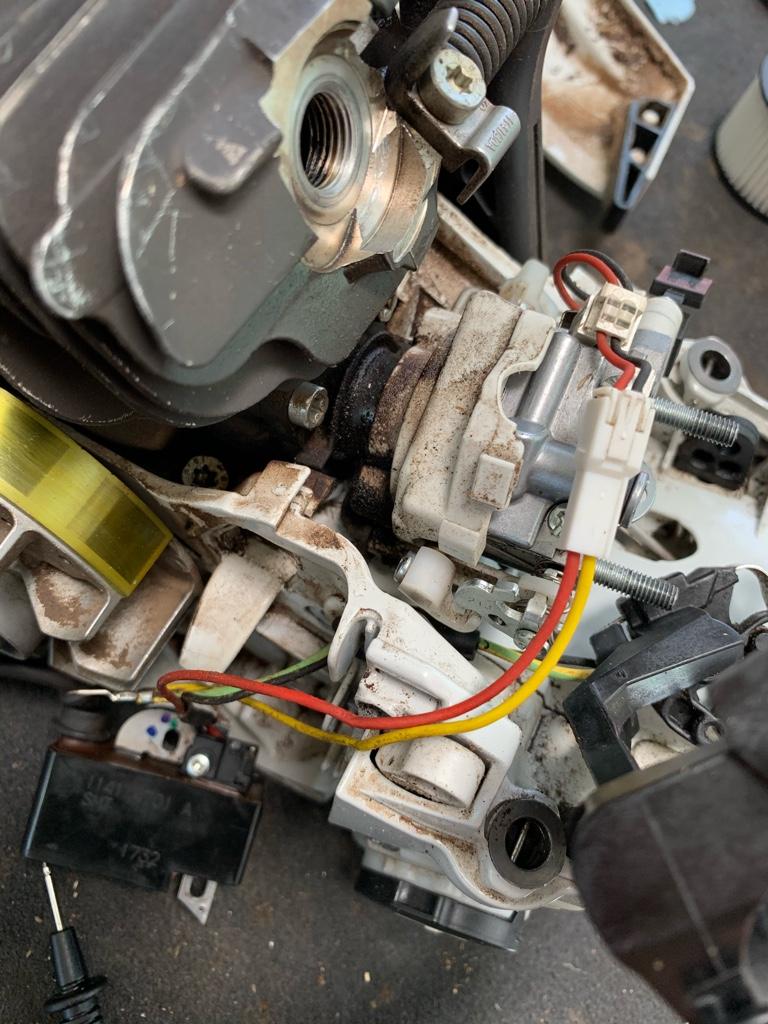

See that smushed yellow wire going from the coil ground ring terminal to the solenoid connector. That is NOT right and shouldn't be smushed. The saw and/or wiring has been incorrectly (re)assembled. This may or may not be your problem but deserves closer inspection.

Also, what is going on with the tape/sleeve on the red/black coming from the coil. Is that factory or an improvised repair? Looks like the wire color changes from red to orange?

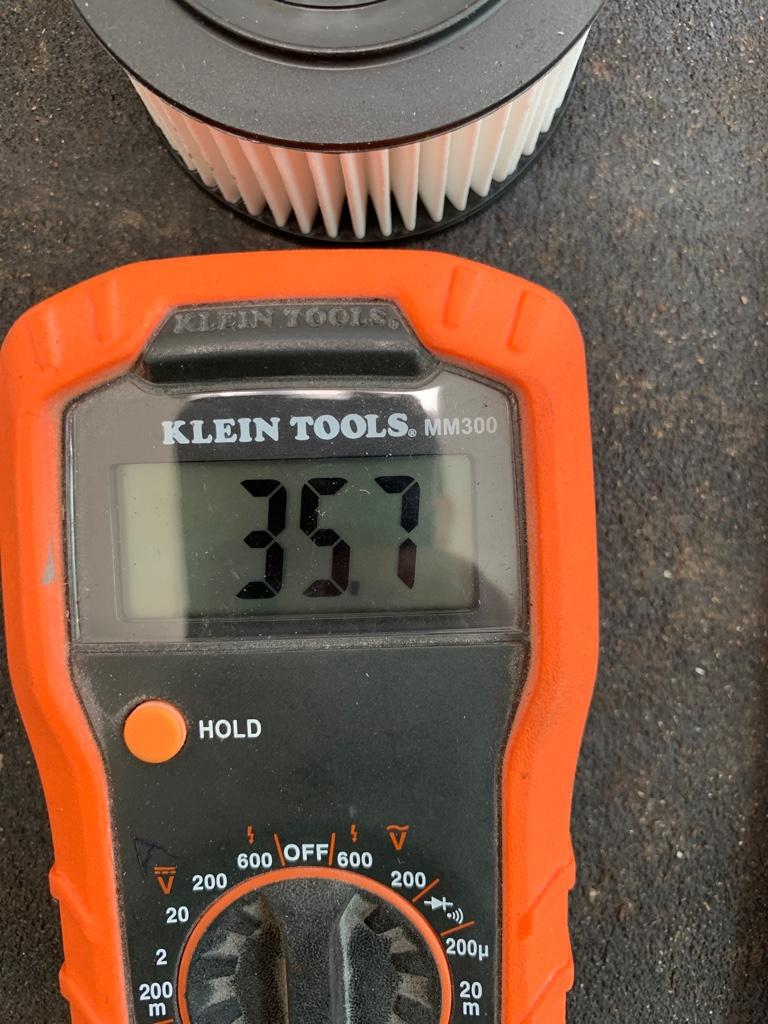

Pull the remaining screw out of the coil and remove that connector. You should be able to measure the solenoid between the yellow ground ring terminal and the red/orange wire.

That tape is protecting the wires from their little spot on the body.

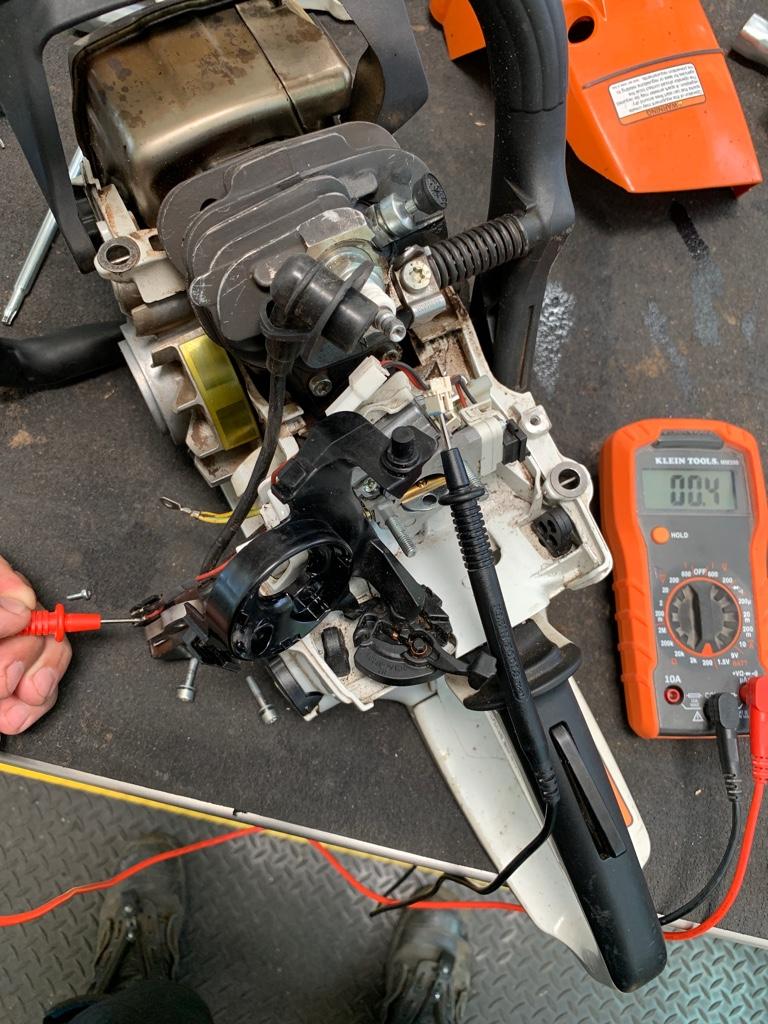

So here is the path of the wires. I’ve checked continuity and resistance between all the connections and as a wording harness fully connected and everything is good so far, last thing is the actual fuel solenoid

Sent from my iPhone using Tapatalk