Holy Sweet Taco Batman!

I Like the bumpers! I am a Yota man myself, my screen name is GPETER for a reason (say it a few times fast).

I have the 220V version of the welder or '175' version of the series.

What are you using to preheat the cast? The reason I ask is that my woodstove poker nees some repair but I was hesitant to weld it because it is cast. Would a MAAP torch work for such a small part (about 1/2" dia)?

Thanks! It redefines a "labor of love". Chainsaw stuff is far cheaper and easier to mod!

I use a MAPP torch for my pre-heat purposes, although you can use a BBQ, or open pit fire, or oxy-acetylene.

If it was structural, I'd recommend using a wire with a high nickel content, which is the easiest way to get a strong weld w/o a lot of resources.

Post heating isn't as important on non-critical items, but its a good habit to get into. The idea is to let the metal cool down nice and slow to make sure everything has time to solidify nicely.

My .02:

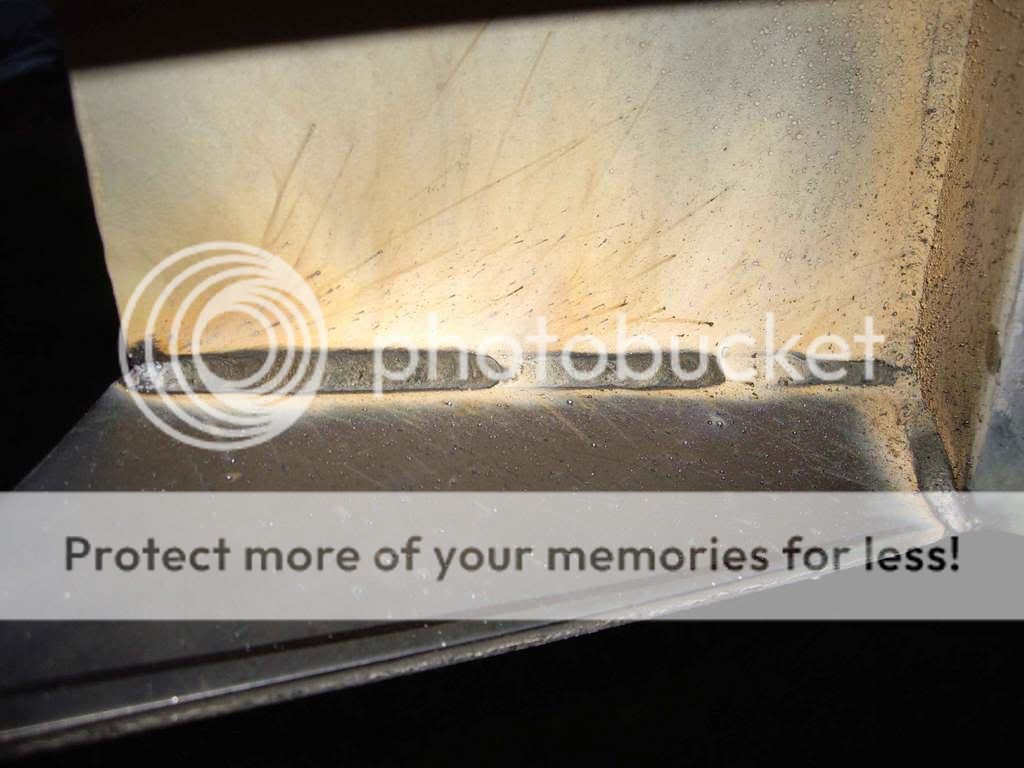

1. Clean the heck out of the area to be welded. DO NOT USE ANY KIND OF BRAKE CLEANER! Starting fluid is okay, just let it evaporate.

2. Heat it up to around 400 or so degrees. If its only a 1/2" in diameter, it won't need much.

3. Weld.

4. Post-heat by keeping the torch on it for a few moments (less than 10 seconds) and slowly draw the torch back

5. Bury it in play sand for a few hours.

6. Chip off slag and grind/finish, etc.

I used this technique to fix a 50+ year old rake for my parents. I use a little bit more of an involved process for welding my axle tubes to my cast differential housing and knuckles, but the basics are there.

A sign of improper pre/post heating is hearing a very light tinkling/pinging noise from the HAZ (heat affected zone) after welding. That's the sound of microscopic cracks forming because the metal is cooling too quickly.