I am thinking double bevel edge. The 4 way would just sink into the soft woods until it would pop. It popped a little more on the piece of cherry.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Advanced hydraulics dual pump splitter build diesel mower conversion

- Thread starter sam-tip

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

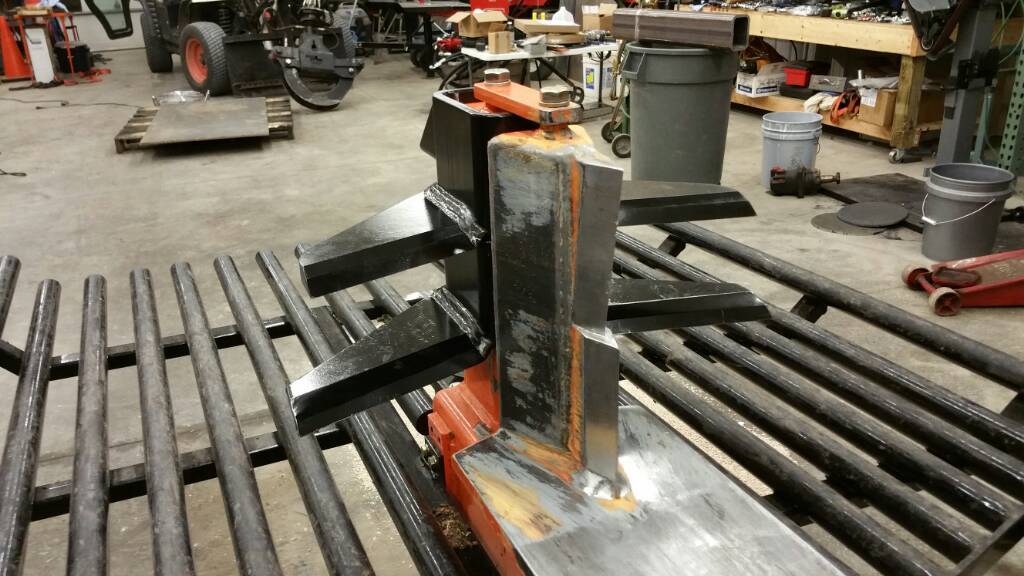

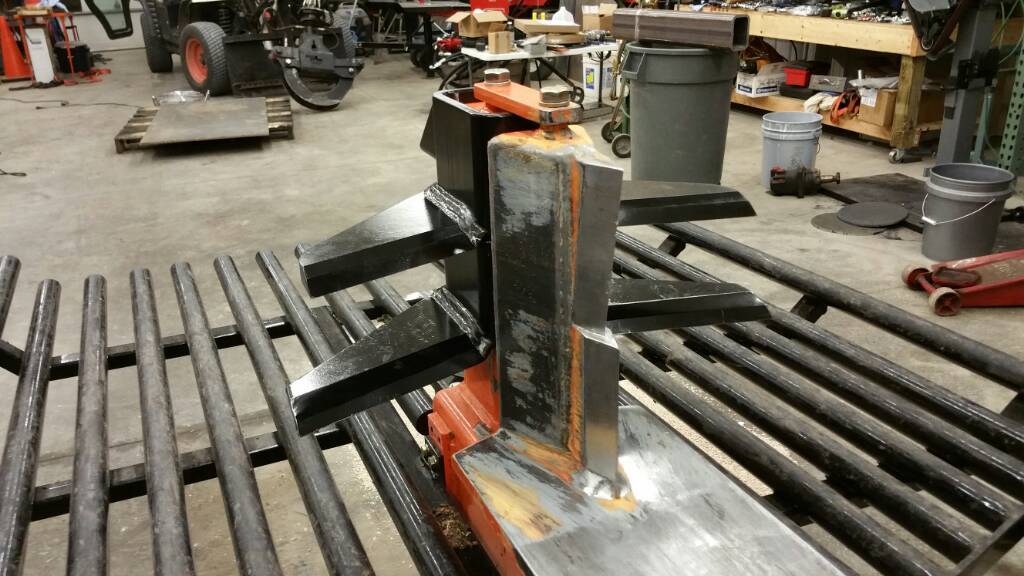

New 4 ways are made. Just need to go pick them up.

Got the wedges today.

Maybe Saturday for video. Just to hot this afternoon. Feel like 100. To hot for September. I will keep the gopro going while splitting so I can explain what it does and doesn't do.

One is 18 inch wide the original is 21 inch

Very pretty, but what is different between the old and the new wedge?

The design looks similar to the old one, minus three inches.

If you add a wing on the back, as in post #193, part of the stress becomes compression across the rear plate as the wing tips push rear ward. The wings real advantage is re-splitting large pieces. I do wish I had made it wider because the top splits are pushed sideways a considerable amount with Timberwolf's wide vertical wedge. I did not make it wider because I thought it would be harder to re-split the lower splits. After using it, 2" wider on each side would be 'more gooder'.

Another observation. Timberwolf's four-way wedge floats. It is annoying actually, because sometimes it is lifted and pushed off by a round. On the other hand, the floating design may reduce stress on the wedge and lift cylinder. What do others think? Timberwolf uses it as a selling point, that the wing can be easily flipped for different size splits, or removed for monster rounds. I just leave it one way myself, and remove the four-way, and the out feed table when towing.

I'd really like to see you try a four-way wedge like mine or jriders on his splitter (Iron and Oak?). I think you would like it. Your splitter build is already way outside the box.

I just noticed too, your outfit table is very wide, which helps get the splits past the four-way wedge for re-splitting. Very nice plus.

The design looks similar to the old one, minus three inches.

If you add a wing on the back, as in post #193, part of the stress becomes compression across the rear plate as the wing tips push rear ward. The wings real advantage is re-splitting large pieces. I do wish I had made it wider because the top splits are pushed sideways a considerable amount with Timberwolf's wide vertical wedge. I did not make it wider because I thought it would be harder to re-split the lower splits. After using it, 2" wider on each side would be 'more gooder'.

Another observation. Timberwolf's four-way wedge floats. It is annoying actually, because sometimes it is lifted and pushed off by a round. On the other hand, the floating design may reduce stress on the wedge and lift cylinder. What do others think? Timberwolf uses it as a selling point, that the wing can be easily flipped for different size splits, or removed for monster rounds. I just leave it one way myself, and remove the four-way, and the out feed table when towing.

I'd really like to see you try a four-way wedge like mine or jriders on his splitter (Iron and Oak?). I think you would like it. Your splitter build is already way outside the box.

I just noticed too, your outfit table is very wide, which helps get the splits past the four-way wedge for re-splitting. Very nice plus.

I took this picture just for fun of it.

I plan on making another wedge later that will be more like the recommended post. 12 x 24 piece of 3/4 AR500 steel.

I will give these a quick test before cutting them up to improve/junk them.

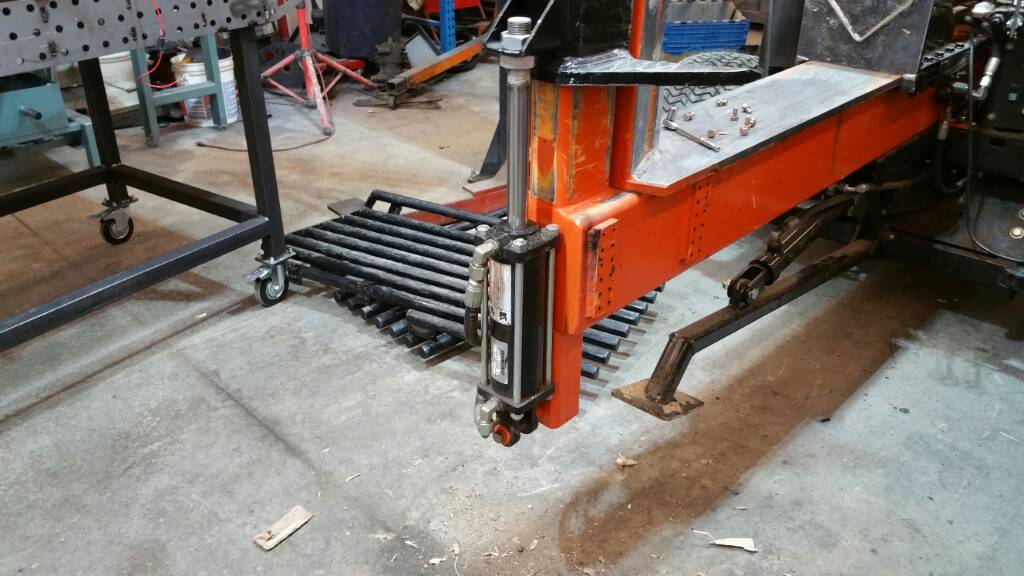

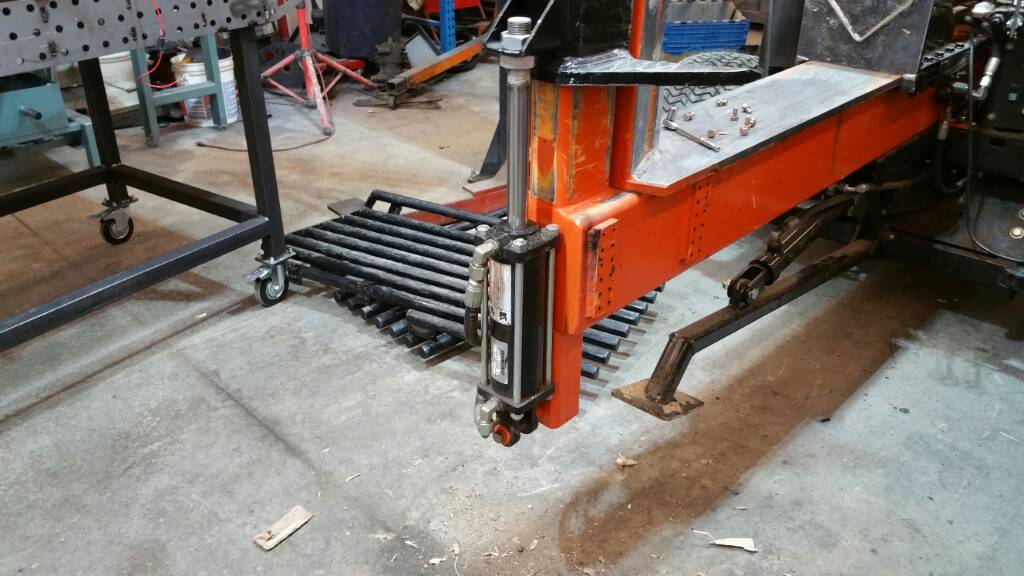

I will also be changing the work table. Will try sheet metal instead of tubes. These 3/16 thick tubes are heavy and wood doesn't slide like I want. Also wider.

I plan on making another wedge later that will be more like the recommended post. 12 x 24 piece of 3/4 AR500 steel.

I will give these a quick test before cutting them up to improve/junk them.

I will also be changing the work table. Will try sheet metal instead of tubes. These 3/16 thick tubes are heavy and wood doesn't slide like I want. Also wider.

Made video of trying to break the new 4 way wedge. Only had one piece fly off this time and got it on video. This was with the original 4 way. The smaller 4 way did much better than the original. The wedge/face angle is change a little on the original. Only tossed the wood half as far as it used to.

Another video of cranking out some wood. I do like the auto cycle valve.

Had to make a repair yesterday. Table was crowded with splits and one pushed sideways and broke one side of the log table. Hooked the tong to the broken hanging wing of table and pulled it back up with winch. Drove to shop and welded it up. Back to splitting 5 minutes later. Did 3.5 cord yeaterday.

Yes but thinking bigger might not be better because of me working by myself. Harder for me to reach the splits to clear the table and fill baskets. But bigger table would hold more splits. A small conveyor at end of table would be nice. Then have conveyor fold up over the top for travel.

Thinking sheet metal on top of next table. The tubes seem to catch the wood and break the table.

Thinking sheet metal on top of next table. The tubes seem to catch the wood and break the table.

Just put some sheet steel on top of your table now. Can use some thinner stuff to to having tubes underneath. I want to put some on my log lift. I need another sheet about the size that's already there, so wood will slide better and easier.Yes but thinking bigger might not be better because of me working by myself. Harder for me to reach the splits to clear the table and fill baskets. But bigger table would hold more splits. A small conveyor at end of table would be nice. Then have conveyor fold up over the top for travel.

Thinking sheet metal on top of next table. The tubes seem to catch the wood and break the table.

Looks good but I have a question. What is the stroke of your splitter? It seems to me you are wasting a lot of time waiting for the pusher to come back to the chunk waiting to be split. Maybe you could add a couple of sides to the beam and put in two or three chunks at a time? Or a stop on the beam if all your chunks are short.

The stroke is 30 inches. Bore is 4.5 with 3.5 shaft. I often double up the pieces. Either one behind the other or one on top of the other. Plus stop it short of returning all the way. But the return stroke is under 2 seconds. So it often returns all the way before I get a chance to stop it when on auto cycle. The wood really flys when doubling up the pieces.

A.E. Metal Werx

Addicted to ArboristSite

Morning all,

Sadly it has been brought to my attention that I should log on here and defend my product/design for the 4-way.

--4-way knife extending forward past the slide tube.

Reasoning: get a more complete 4-way split.

--Angled 4-way knife towards the front-pusher.

Reasoning: helps keep the wood sucked in towards the center vs being easily pushed out.

As for the broken 4-way, cause was a defect in the slide tube.

Everyone has there idea for an ideal set up. I use mine because it has proved to work great in the several splitters I have out there. Sucks that one defect has put all my work in jeopardy. I will add that the broken 4-way was replaced in a timely manner at no charge. Just like it should be. Sucks that his machine was down for the time it was.

Sadly it has been brought to my attention that I should log on here and defend my product/design for the 4-way.

--4-way knife extending forward past the slide tube.

Reasoning: get a more complete 4-way split.

--Angled 4-way knife towards the front-pusher.

Reasoning: helps keep the wood sucked in towards the center vs being easily pushed out.

As for the broken 4-way, cause was a defect in the slide tube.

Everyone has there idea for an ideal set up. I use mine because it has proved to work great in the several splitters I have out there. Sucks that one defect has put all my work in jeopardy. I will add that the broken 4-way was replaced in a timely manner at no charge. Just like it should be. Sucks that his machine was down for the time it was.

Don't let any naysayers get to you. Crap happens sometimes and it's not whether something broke, it's whether the product was stood behind.

sent from a field

sent from a field

New table in the works.

Similar threads

- Replies

- 93

- Views

- 4K

- Replies

- 17

- Views

- 2K

- Replies

- 28

- Views

- 3K