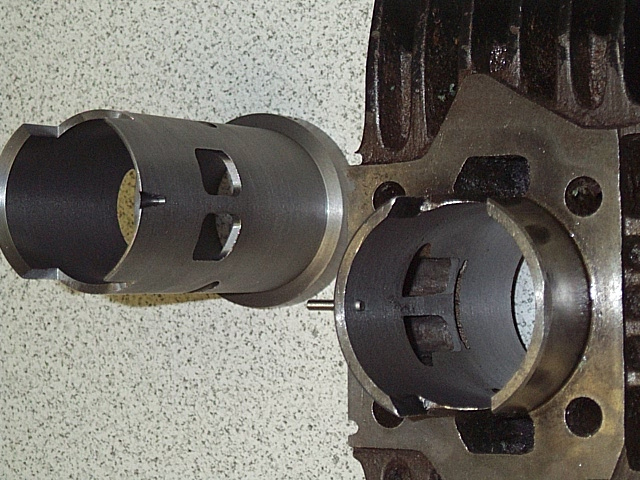

Hi forum, I have a little doubt, a friend have a very old chainsaw from its father, and he want to preserve the 2-S cylinder, I mean the original, but he re-plated the cylinder two times and with a very poor result, so... here I am, when no one ask me about the topic, I talked, and I recommended him to use a sleeve, and again, when someone ask me if I can do that (I have to say no) but I said yes.

So, I know that the sleeves are made with cast iron, but do anyone have a concrete specification and tolerance? or just go to the metal shop and buy a cast iron pipe and turning with the lathe. I guess like piston rings are made with cast iron... but before doing a total mess, I wonder...

Thanks!

So, I know that the sleeves are made with cast iron, but do anyone have a concrete specification and tolerance? or just go to the metal shop and buy a cast iron pipe and turning with the lathe. I guess like piston rings are made with cast iron... but before doing a total mess, I wonder...

Thanks!