So that's the issue. Chainsaw carbs in general give a fuel mixture that varies wildly with changing air velocity (rpm at WOT), getting much richer with only a small increase in air velocity through the venturi. The carbs on the Echo 590 have a fixed H jet set up to supply most of the fuel with the H needle providing only a small trim to that fuel - a small adjustment range on what is basically a fixed H jet carb.

With an effective muffler mod increasing the air velocity through the carb (which is just like increasing the rpm that causes 4-stroking), the mixture is now richer and out of range of the small H adjustment.

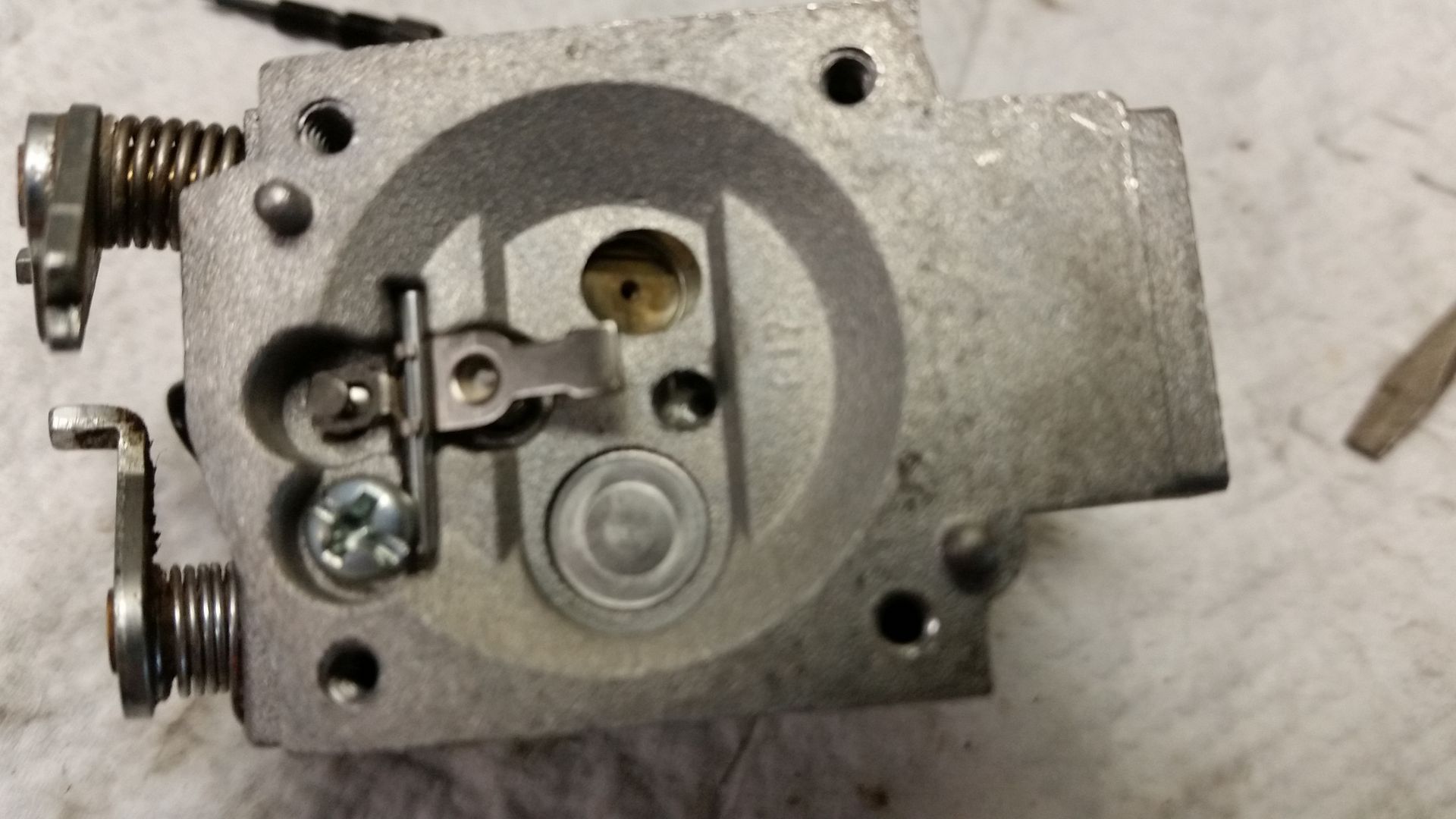

These carbs are not accurate enough for what Echo is trying to do without even a cat. The basic inaccuracy of the carbs is really what AT was intended to address - creating an all position fuel system that can also hold a fixed mixture.

No need to try to complicate things with a pile of technical garb, these Echo saws run real good when tuned right which not very hard to do. Plenty of vids on youtube with them cutting right with or really close to real good Husky and Stihl saws . This aint rocket science ,its a chainsaw. Steve