2coldHere

ArboristSite Lurker

Hi all, I'm new here, hoping I can get some help with a 1970's era Didier wood splitter that I picked up recently (VERY used, passed thru many hands it seems) that just can't get to run right.

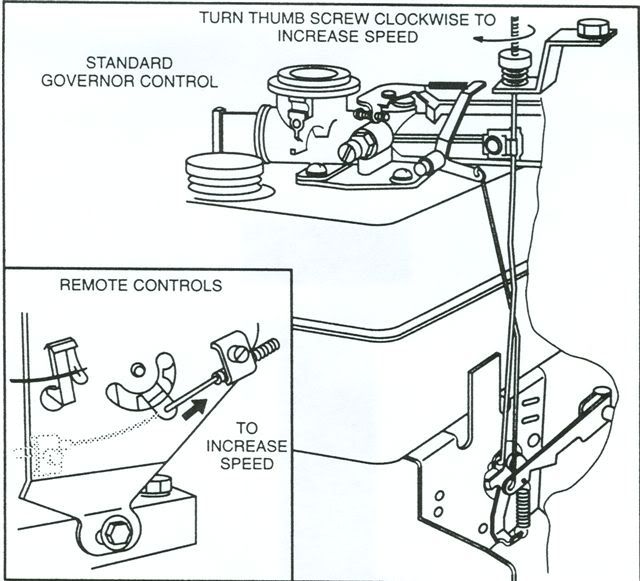

Anyone have a manual for the engine, carb, and carb linkages?

The splitter is a Didier Model HA19M, Code 8G, Serial 217507. The hydraulic pump is Model 205-2266, Serial D11928. Engine is B&S 5HP. For the life of me I can't find a serial or model number stamped anywhere on the engine, so that's part of my problem: can't look up how the engine is "supposed to be" without knowing the engine & carb type/model.

Symptoms when I first got it: always had to pull out the choke (cylinder-slide type, looks like a Briggs "Pulsa-Jet" type carb) to start it, even when it was hot; the choke won't stay out by itself so I had to hold it out with my left hand while pulling the starter rope with my right hand, sort of an awkward move but there wasn't any other way. Once it started I could push the choke back in and it ran sort of ok. I could see the choke cylinder bouncing in & out while the engine was running and I knew that wasn't right but wasn't sure if it was just because there wasn't any friction anymore to hold the choke cylinder still, or if it was doing it on purpose to suck in more gas when needed (I don't know these kinds of carbs well). Then it started running rough, stalling, and finally didn't want to run at all unless I removed the air cleaner and squirted starter fluid into the carb. I figured it just needed a good cleaning.

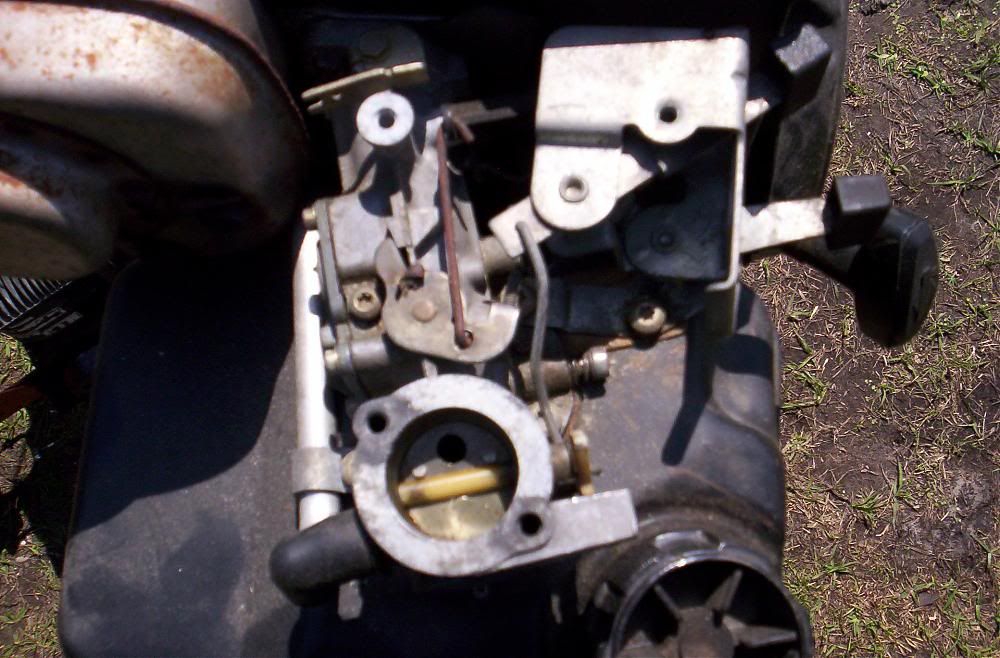

I removed the carb and its mounting bracket from the engine, removed it from the gas tank, and found everything was really dirty and the inlet screens were covered with debris. Cleaned the whole carb very well (also cleaned the air filter's foam, and re-oiled the foam afterwards), also cleaned the inside of the gas tank - had to sandblast a couple rusted spots in the tank; very gently cleaned the carb's diaphram and saw it was in good shape, spring seemed to still be good, no tears visible in the diaphram. I re-assembled everything but was confused about all the linkages & springs for the throttle and governor system (that's where I think my problem is; I think it's missing a spring or two, maybe a connecting rod for the governor system, and maybe I put things together wrong?).

New symptoms: still have to pull the choke out to start it, and I have to pull the starter cord maybe 6 or 7 times before it'll start, even when it's hot. Can't get the mixture screw set right: I set it to the default 1-1/2 turns as a starting point; and it does the surge-stall high/low rpm thing where the governor keeps pulling on the throttle, then letting go when it gets to a higher rpm. If I screw the screw in, it smooths out quite a bit but just as it gets to where it's sounding "almost right" it stalls and won't restart until I turn the screw back out a quarter turn or more. When I start from default and screw it out more, the surge-stall thing gets more severe and the engine backfires like crazy.

Any help would be appreciated. The leaves are already falling and it's getting chilly & windy, and I've got a big pile of logs to split before the cold sets in. I don't have the money to take it to a "repair shop" so I'm on my own in diagnosing & fixing it. I rebuild my kids' dirt bike and ATV engines (2 and 4 stroke) and my lawnmower engines and fix everything on my cars except transmissions, so I'm handy enough to fix it; I just need to know what it's supposed to look like, especially the carb linkages to/from the governor system.

Anyone have a manual for the engine, carb, and carb linkages?

The splitter is a Didier Model HA19M, Code 8G, Serial 217507. The hydraulic pump is Model 205-2266, Serial D11928. Engine is B&S 5HP. For the life of me I can't find a serial or model number stamped anywhere on the engine, so that's part of my problem: can't look up how the engine is "supposed to be" without knowing the engine & carb type/model.

Symptoms when I first got it: always had to pull out the choke (cylinder-slide type, looks like a Briggs "Pulsa-Jet" type carb) to start it, even when it was hot; the choke won't stay out by itself so I had to hold it out with my left hand while pulling the starter rope with my right hand, sort of an awkward move but there wasn't any other way. Once it started I could push the choke back in and it ran sort of ok. I could see the choke cylinder bouncing in & out while the engine was running and I knew that wasn't right but wasn't sure if it was just because there wasn't any friction anymore to hold the choke cylinder still, or if it was doing it on purpose to suck in more gas when needed (I don't know these kinds of carbs well). Then it started running rough, stalling, and finally didn't want to run at all unless I removed the air cleaner and squirted starter fluid into the carb. I figured it just needed a good cleaning.

I removed the carb and its mounting bracket from the engine, removed it from the gas tank, and found everything was really dirty and the inlet screens were covered with debris. Cleaned the whole carb very well (also cleaned the air filter's foam, and re-oiled the foam afterwards), also cleaned the inside of the gas tank - had to sandblast a couple rusted spots in the tank; very gently cleaned the carb's diaphram and saw it was in good shape, spring seemed to still be good, no tears visible in the diaphram. I re-assembled everything but was confused about all the linkages & springs for the throttle and governor system (that's where I think my problem is; I think it's missing a spring or two, maybe a connecting rod for the governor system, and maybe I put things together wrong?).

New symptoms: still have to pull the choke out to start it, and I have to pull the starter cord maybe 6 or 7 times before it'll start, even when it's hot. Can't get the mixture screw set right: I set it to the default 1-1/2 turns as a starting point; and it does the surge-stall high/low rpm thing where the governor keeps pulling on the throttle, then letting go when it gets to a higher rpm. If I screw the screw in, it smooths out quite a bit but just as it gets to where it's sounding "almost right" it stalls and won't restart until I turn the screw back out a quarter turn or more. When I start from default and screw it out more, the surge-stall thing gets more severe and the engine backfires like crazy.

Any help would be appreciated. The leaves are already falling and it's getting chilly & windy, and I've got a big pile of logs to split before the cold sets in. I don't have the money to take it to a "repair shop" so I'm on my own in diagnosing & fixing it. I rebuild my kids' dirt bike and ATV engines (2 and 4 stroke) and my lawnmower engines and fix everything on my cars except transmissions, so I'm handy enough to fix it; I just need to know what it's supposed to look like, especially the carb linkages to/from the governor system.