A family friend gave me this jack and decided to use it to make a log lifter for the stove. Normally not a big deal as if I can pick it up, I'll burn it. This year I'm going to have shoulder surgery and be one armed through most of the heating season so I needed to come up with something before then. I had loaded the furnace house prior to all this and have 15 cord in there. Didn't want to bother family and friends to load so this is why I'm doing this. Don't want to modify the jack that it can't be put back and used normally so we'll see what we can come up with.

Here is the jack. It is an older bumper jack style and has quite a bit of lift to it. It has safety locks in the siderails that will hold in case the jack gives way. Hand pump is on an eccentric and has a high release on the back side. Really a nicely build jack.

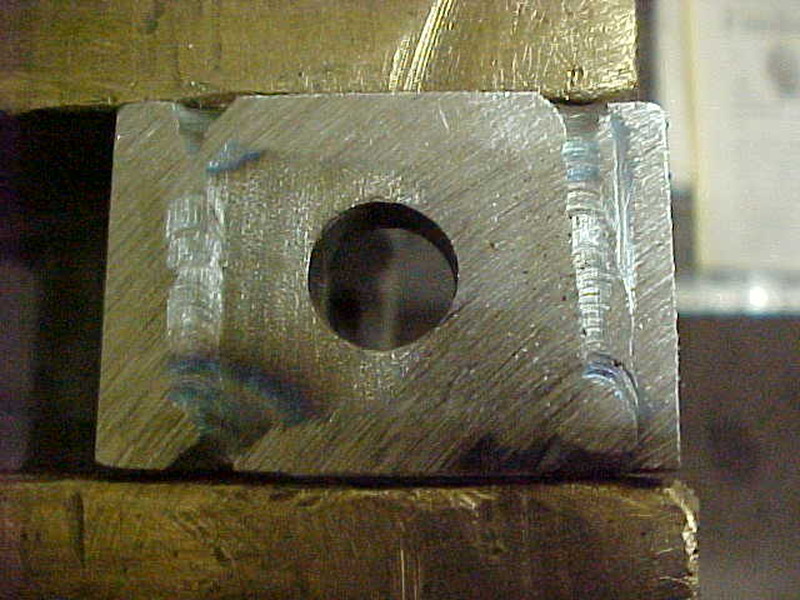

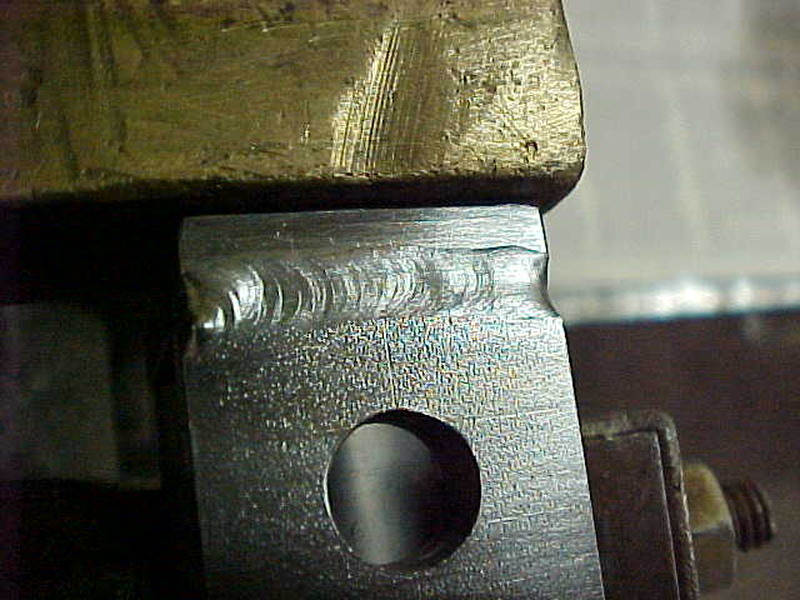

The rails with pads slide out and are adjustable, width wise. Jacks piston was froze and pin sheared off so I took it all apart and pressed the piston out. Cleaned the bore and piston and O ring was fine. Put it all back together and it works fine with no leaks. Kind of happy about that one!

Here is is at full up and it has more than enough reach to get into the boiler.I just have to come up with a holder for the rounds. I want to stand them on the end and then just push them over into the stove. One big round a load will be fine.

Just a little over 29 inches high as you can see.

The extendable arms have a pin that keeps them from over extending. One pin and a spring clip is what holds them in. that was easy.

I'll put these away to use them when I'm back to normal.

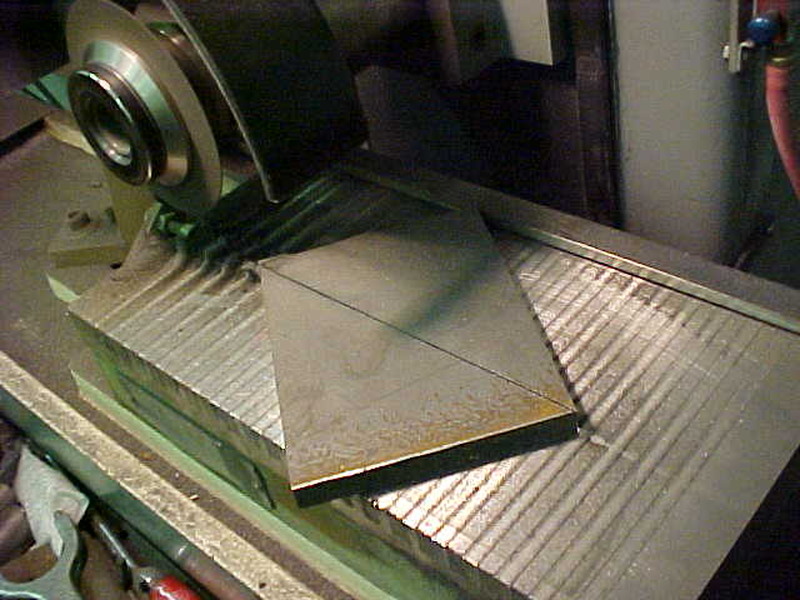

My plan is to extend another box beam out to the edge of the feet. That should be more than enough to keep them there. There are no wheels on the from of this so that will have to be addressed too. It was designed to roll in place and let it rest on the floor to jack. I want to roll the weight around.

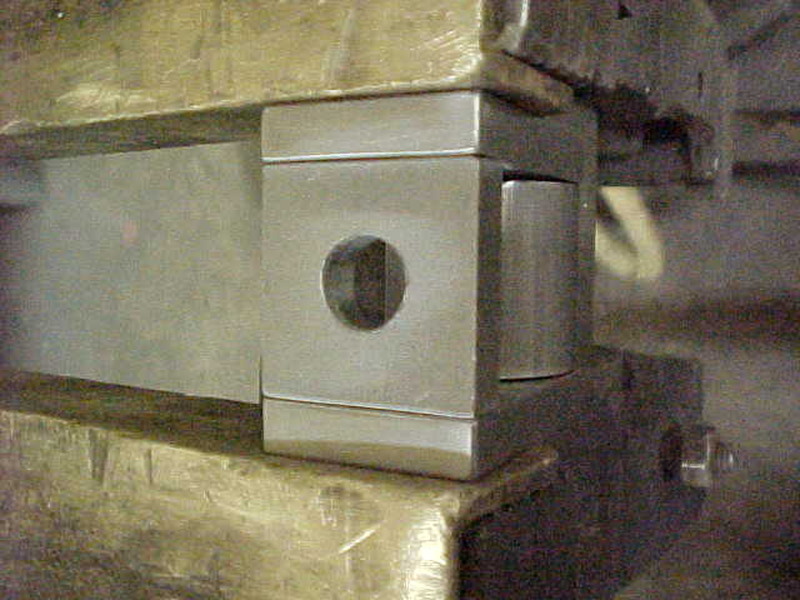

2 thicknesses of 1 1/2" box gets me level. I'll do shorts on the ends so it clears the center bracket.

Here is the jack. It is an older bumper jack style and has quite a bit of lift to it. It has safety locks in the siderails that will hold in case the jack gives way. Hand pump is on an eccentric and has a high release on the back side. Really a nicely build jack.

The rails with pads slide out and are adjustable, width wise. Jacks piston was froze and pin sheared off so I took it all apart and pressed the piston out. Cleaned the bore and piston and O ring was fine. Put it all back together and it works fine with no leaks. Kind of happy about that one!

Here is is at full up and it has more than enough reach to get into the boiler.I just have to come up with a holder for the rounds. I want to stand them on the end and then just push them over into the stove. One big round a load will be fine.

Just a little over 29 inches high as you can see.

The extendable arms have a pin that keeps them from over extending. One pin and a spring clip is what holds them in. that was easy.

I'll put these away to use them when I'm back to normal.

My plan is to extend another box beam out to the edge of the feet. That should be more than enough to keep them there. There are no wheels on the from of this so that will have to be addressed too. It was designed to roll in place and let it rest on the floor to jack. I want to roll the weight around.

2 thicknesses of 1 1/2" box gets me level. I'll do shorts on the ends so it clears the center bracket.