I do a lot of pullovers on property, hazard trees and leaners. While it's very case by case, here's a rough breakdown of how I go about it;

Assess the tree for solidity. You're own experience counts here. For me its a visual, sounding with the back of an axe or hammer, in rare cases make a vertical borecut right down low to see how it is. Consider all the usual stuff; hangers, likely snapouts, debris fallout, escape route etc.

Figure the weight and how much pulling power I need. It's not as easy as it seems to assess the weight on a big heavy leaner, but a plumb bob is a good start for complex trees. All your gear needs to carry all that weight in the worst case scenario (hinge fails)

Set ropes. It's often just a single line, high up but not too high if it's a dead top that can snap out. If the tree has side lean also I'll set a side pull to counter that, particularly if the tree is dead or brittle.

Work out my rigging. I prefer mechanical advantage over winches, and use a vehicle only as a last resort because they're too unreliable. Speed is often less important than control. I'll often end up with stacked 2:1's or 3:1's. Very few trees will need more than 12:1 with 1 or 2 men on the rope pulling. I like to use progress capture on my final pulley (prussik or camming pulley) so the guys can't "lose it". Remember to stack your gear with the strongest ropes and pulleys at the business end of the system.

Pre-tension your ropes. If there's a side pull, I'll start with that. Stand a good distance off and perpendicular to the pulley (standing in the lay) and have someone tension that side pull as you watch the top. Take up only just enough tension for the top to move a few inches. The camming pulley/progress capture is critical to maintaining that tension with precision. The side weight has now been removed and the hinge has support. If it fails it will still swing with the side pull. Now go to the side and use the same procedure to tension the main pull. It's important not to overtension because you can setup a barber chair scenario. People with vehicles/winches often overtension.

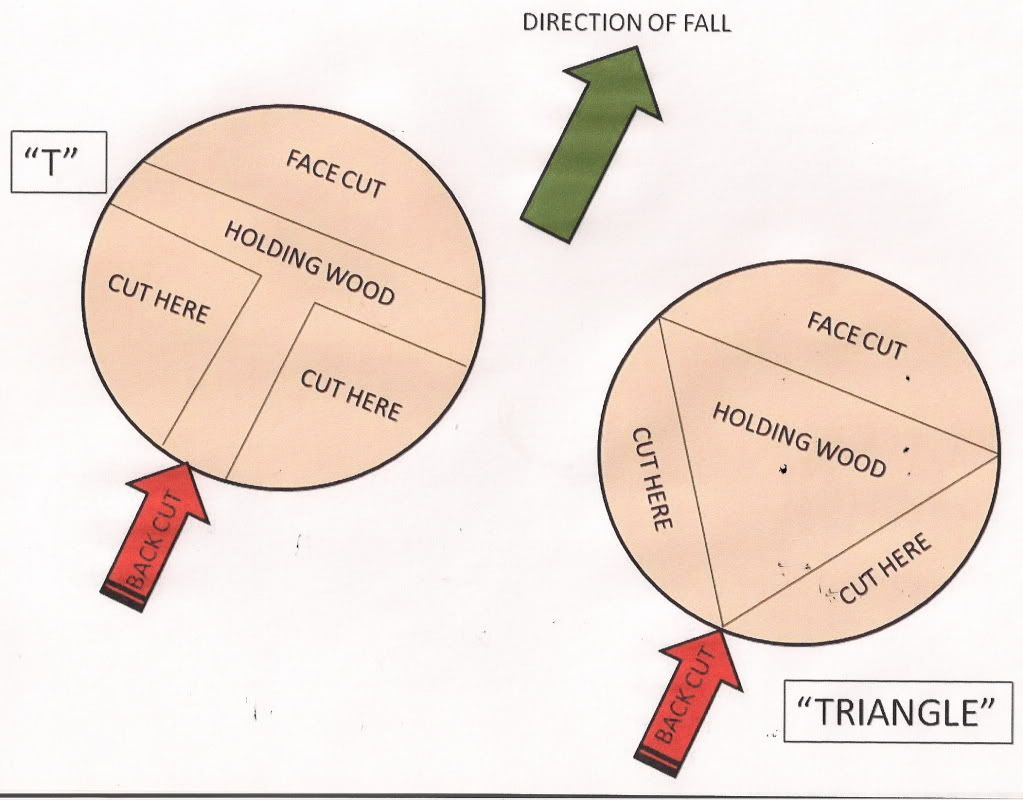

Now cut your scarf. Mark it out with chalk if you need to, no shame in that. Take your time, make that scarf perfect. Have someone watch the far side if it's big/critical or you're not confident. It's going to be a mess if you have to re-cut it, so plan it out and get it right. You can use whatever face works, I'll often use a humboldt with a snipe to throw the tree a bit. The block out face with a snipe has a bit of extra flex for some trees and gives you very precise control on when she pops off the stump.

Make your back cut. I just make a straight back cut, setting wedges as I go. I cut slow, and keep an eye on the kerf. If it starts opening, you've got too much tension on your ropes and are in danger of barberchairing. Back off on the ropes. If it starts closing, no big deal. Just tension the ropes a *little* more. Keep progressing until you're happy with the size of the hinge. Don't overcut the hinge. Shut your saw off, put it away. The tree is held in place by the rope(s). Have the guys on the pull ropes start pulling her over. I'll usually stay and keep the wedges snug just in case. Sometimes I'm the guy on the pull rope, and the only guy there so I'll just leave a couple wedges in but not overpound them (you can snap out a brittle hinge!). Wedges add unnecessary risk in a pullover and should be used only for backup, not for wedging over.

That's the basic setup. Sounds complex but it's pretty straightforward in practice. There are endless variations - the side pull can be ahead or behind the tree for swing effects, you can take in or pay out as the tree goes over on the side pull also. On really bad trees I've used butt tie offs in some cases. The bore cut has it's place but I could see it being very easy to overtension since you've got no indication of tension without a back cut. The common recipe for disaster that I see is the use of a vehicle, poor communication and a big hurry. They overtension, make a messy face and sloppy back cut and the guy in the vehicle takes off too early and too fast. A good pullover doesn't need to happen in a hurry. You can have a cup of tea as it's coming over.

Shaun