You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

husky 350/346xp project

- Thread starter Red97

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Ironworker

Addicted to ArboristSite

Nice, keep us updated please.

Looks good buddy. I think the lathe needs to be a little bigger.

Thank you

This one will have to do. We got rid of the 36x144 inch. A couple years ago...

Nice, keep us updated please.

Thank you,

This might take a bit but I will keep updated, first time I have rebuilt a saw without reed valves.

Here is my bolt for bolt 350 vid series...

Might help

Might help

sunfish

Fish Head

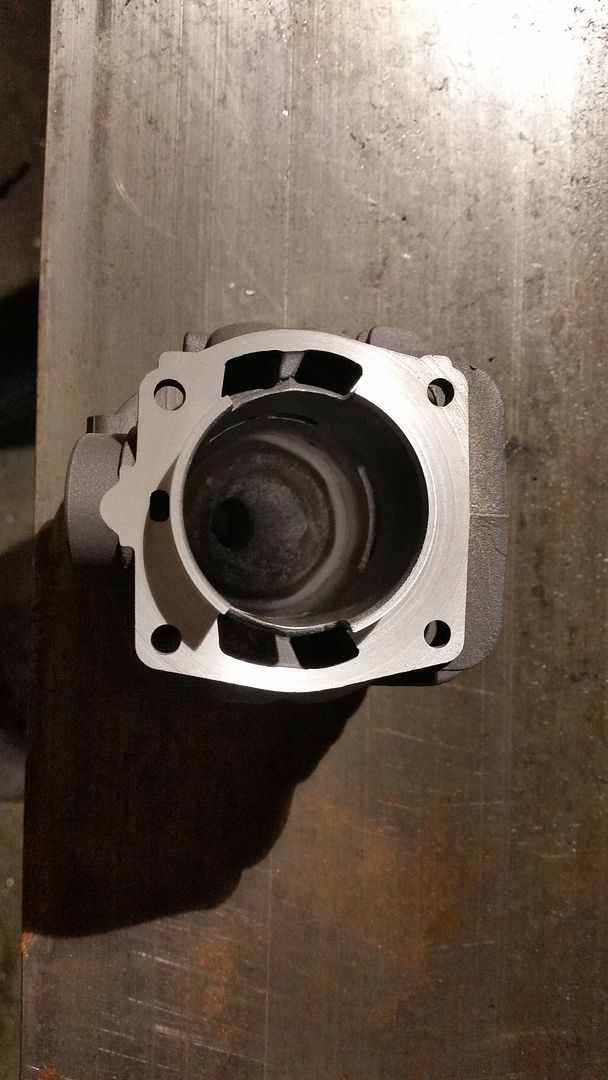

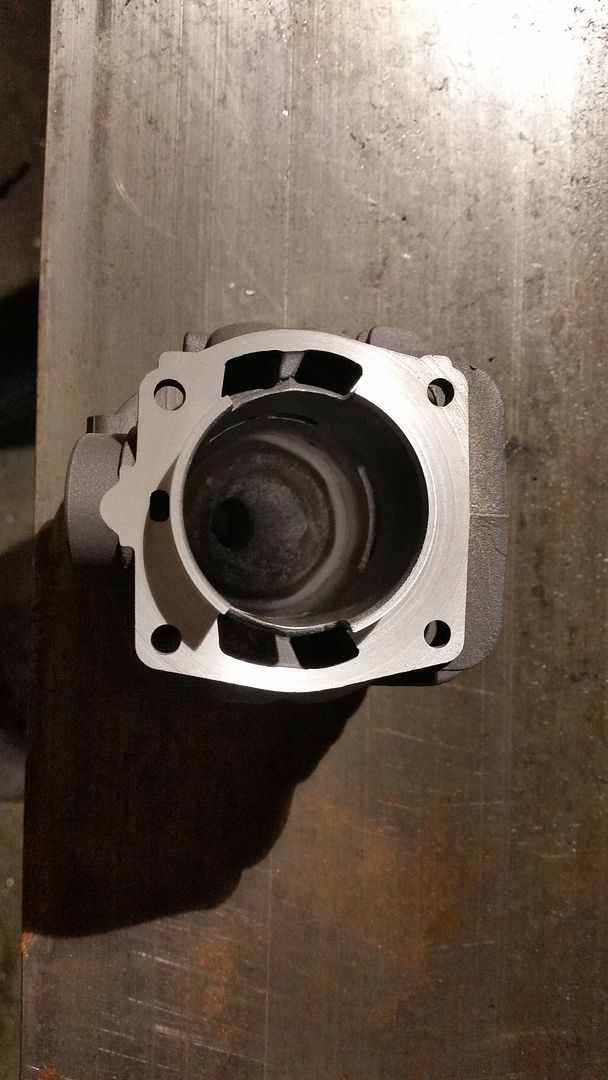

Machine work looks good. Is a AM cylinder?

Machine work looks good. Is a AM cylinder?

Yep the cheap closed port 346xp.

Ironworker

Addicted to ArboristSite

I used a hyway top end that I did a mild port job on a 353 and was impressed with it to say the least.Yep the cheap closed port 346xp.

My hyway top end has been good too...runs just fine

Sty57

Tree Freak

I'm with you on that one.I would appreciate learning the process to make the mandrel that cuts the squish. Especially with regard to how you cut the tool-bit groove.

Thanks, Brian

Ironworker

Addicted to ArboristSite

I triple that, I believe there is a thread on it, but not very detailed from what I remember.I'm with you on that one.

Thanks, Brian

I think we need just one...anyone who needs it pays shipping. Like passing a baton

But with all that cast iron....no vibration and a better finish possible. Awesome job BTW! Inspirational. AND

I too have done the squish band single point with a 4 jaw chuck. A PITA vs. your "fly" cutter. Doubt after all is said and done the finish is any better single point vs. what you have on that rigid machine! Like your choice of Tachs too... What range of bore diameters can that handle? Is the cut angle/slot for tool in the 8-10 degree range? Clearance angle on the end?

Derf

Addicted to ArboristSite

Looks like maybe 35 thou taken off? Just judging by how much of the intake was left untouched. I've seen some who take off so much almost the whole bottom side of the intake flange is flat.

The cylinder is only aluminum, pretty soft. Removing 40 thou is almost like a pass and a finishing pass. Even smaller lathes can produce good finish, as long as your cutter is sharp, your sfps and ips are set right, and you know what you're doing.But with all that cast iron....no vibration and a better finish possible.

I've seen some of this questions come up in Carl's (MillerModSaws) thread when he showed his mandrel. I wonder if I could get away with using my boring bar to cut squish?What range of bore diameters can that handle? Is the cut angle/slot for tool in the 8-10 degree range? Clearance angle on the end?

I think we need just one...anyone who needs it pays shipping. Like passing a baton

Let's make it out of UHMW plastic instead of metal, will save on shipping. [emoji6][emoji106]

The cylinder is only aluminum, pretty soft. Removing 40 thou is almost like a pass and a finishing pass. Even smaller lathes can produce good finish, as long as your cutter is sharp, your sfps and ips are set right, and you know what you're doing.

I've seen some of this questions come up in Carl's (MillerModSaws) thread when he showed his mandrel. I wonder if I could get away with using my boring bar to cut squish?

I cut with a boring bar but do single point vs. using it like a form tool. Went from the side wall, in depth of cut... fed towards the middle. It's OK. Just my setup time sucks right now. Working on a better plan. Like you said Aluminum is soft and old fashion positive rake tooling works well enough.

I would appreciate learning the process to make the mandrel that cuts the squish. Especially with regard to how you cut the tool-bit groove.

Honestly all I did was face both ends of the mandrel on the lathe. I chucked it in the vice with indicated it 0-0 across the top. I used the live center mark on the end of the mandrel, to cut the slot offset from center. that way I can grind my tool bit to only cut at the largest diameter. I just cut the slot with a 1/4" finishing endmill. I have one set screw on the cutting side of the mandrel, to set the tool angle up or down. I cut about a .015 relief on the front side to clear chips, I lest the other 3/4 of the mandrel flat and square to help keep the squish square.

But with all that cast iron....no vibration and a better finish possible. Awesome job BTW! Inspirational. AND

I too have done the squish band single point with a 4 jaw chuck. A PITA vs. your "fly" cutter. Doubt after all is said and done the finish is any better single point vs. what you have on that rigid machine! Like your choice of Tachs too... What range of bore diameters can that handle? Is the cut angle/slot for tool in the 8-10 degree range? Clearance angle on the end?

Hey be nice to my finish, all my carbide was chipped.

You lost me a little bit on you question. when I cut the slot I cut it as close to 0* I could. but with the set screw I can shim it up if I need.

Looks like maybe 35 thou taken off? Just judging by how much of the intake was left untouched. I've seen some who take off so much almost the whole bottom side of the intake flange is flat.

The cylinder is only aluminum, pretty soft. Removing 40 thou is almost like a pass and a finishing pass. Even smaller lathes can produce good finish, as long as your cutter is sharp, your sfps and ips are set right, and you know what you're doing.

I've seen some of this questions come up in Carl's (MillerModSaws) thread when he showed his mandrel. I wonder if I could get away with using my boring bar to cut squish?

Let's make it out of UHMW plastic instead of metal, will save on shipping. [emoji6][emoji106]

yep .035 off, the mandrel is alum so it is not much heavier than the plastic one.

Disclamer I have never made anything like this. I have no clue how this will work or not. just copying pics from the web. and talking with people who have done this before me.

I do appreciate the feedback thanks for the help. Keep it coming

Joe

Derf

Addicted to ArboristSite

Honestly all I did was face both ends of the mandrel on the lathe. I chucked it in the vice with indicated it 0-0 across the top. I used the live center mark on the end of the mandrel, to cut the slot offset from center. that way I can grind my tool bit to only cut at the largest diameter. I just cut the slot with a 1/4" finishing endmill. I have one set screw on the cutting side of the mandrel, to set the tool angle up or down. I cut about a .015 relief on the front side to clear chips, I lest the other 3/4 of the mandrel flat and square to help keep the squish square.

Disclamer I have never made anything like this. I have no clue how this will work or not. just copying pics from the web. and talking with people who have done this before me.

I do appreciate the feedback thanks for the help. Keep it coming

Joe

Good work Joe,

For you or anyone else who wants more info, here is Carl's thread on making a mandrel.

http://www.arboristsite.com/community/threads/mandrel-style-squish-band-cutter.276342/

And here's Scott's (Treemonkey) thread on cutting Squish by hand.

http://www.arboristsite.com/community/threads/cutting-squish-by-hand.272682/

I'd appreciate if you could post what your timing numbers are after that cut. And if you get a chance what your compression is once you seal this back up. Please and thanks very much!yep .035 off, the mandrel is alum so it is not much heavier than the plastic one.

And if you bore out the mandrel from the backside you could save even more weight.

Similar threads

- Replies

- 8

- Views

- 1K