Are you going to give this saw to your BIL when you get done? I knew he said he was looking for one when he was at the gtg.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Husky 350 Port Job

- Thread starter blsnelling

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

rms61moparman

Addicted to ArboristSite

Are you going to give this saw to your BIL when you get done? I knew he said he was looking for one when he was at the gtg.

Anthony will be one lucky son-of-a-gun if he gets that one.

It gonna be a hard one to turn loose of.

It's gonna be interesting to see how this setup runs when done by a REAL porter and not a hack like me.

I'm still amazed at how mine runs despite my butcher job.

Mike

ronT2

ArboristSite Guru

Good to know that there is a Meteor alternative to the Golf. So….do you plan on running a 359 carb on it?

It's gonna be interesting to see how this setup runs when done by a REAL porter and not a hack like me.

I'm still amazed at how mine runs despite my butcher job.

Yeah, we know how your self-proclaimed "junk" runs

I know when to bring a gun to a gun fight

I know when to bring a gun to a gun fightHow's this for free? Well, I did have to repair another saw, and got this for payment, but still!

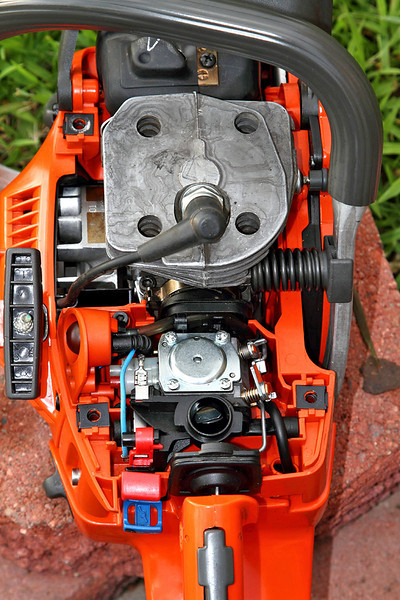

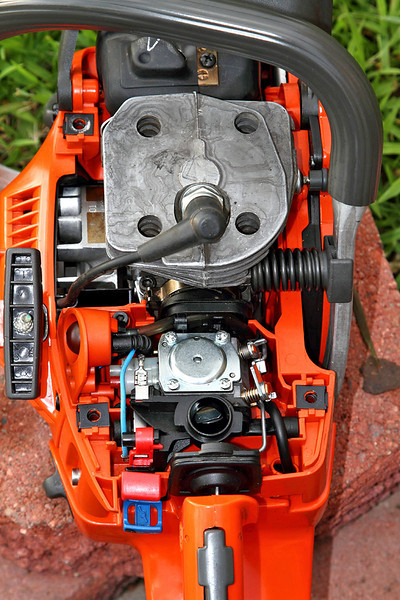

The saw has no real run time on it with the new piston. I've only warmed it up a couple times. Even with a heavily hand-sanded and then honed cylinder, with one remaining scratch, compression is already 150 PSI. That will go up as the cylinder smooths and the rings break in. Squish was .019" without a gasket.

I hope to get it in some wood tomorrow. Only then will I tune the H too see what it's going to turn. I did replace the 13,000 RPM rev limited coil with an unlimited one.

I hope to get it in some wood tomorrow. Only then will I tune the H too see what it's going to turn. I did replace the 13,000 RPM rev limited coil with an unlimited one.

rms61moparman

Addicted to ArboristSite

That one is a LOT prettier than mine!

Where's the vids of it outcutting your 346???

Mike

Where's the vids of it outcutting your 346???

Mike

That one is a LOT prettier than mine!

Where's the vids of it outcutting your 346???

Mike

Hasn't seen wood yet. Hopefully tomorrow.

rms61moparman

Addicted to ArboristSite

I wish my squish had come in that tight!!!

Oh well........maybe someday!......................Right Nik???LOL

Mike

Oh well........maybe someday!......................Right Nik???LOL

Mike

parrisw

Tree Freak

Dam that thing looks brand new!!!!!!!! What do you use to clean it up?

little possum

Crash and Burn

I want to know how come all your saws are so clean?

Looks real good. Did you mod the muffler?

Looks real good. Did you mod the muffler?

I want to know how come all your saws are so clean?

Looks real good. Did you mod the muffler?

Because I just cleaned it up

Dam that thing looks brand new!!!!!!!! What do you use to clean it up?

I disassembled the saw and cleaned it in my parts washer full of Mineral Spirits/Paint Thinner. It's quick and works well. I probably spent an hour or less on cleaning, and it's nearly brand new clean.

little possum

Crash and Burn

Oh, parts washer, I knew there was a reason I was supposed to save some money instead of buying more saws to put in the parts washer.

Anywhos, great work. And Im interested in your comparison.

Anywhos, great work. And Im interested in your comparison.

It's just a cheapie from HF. The solvent actually cost more than the washer itself.

No, the ports aren't all polished and shinny. This will be a work saw, and it's not trying out for any beauty pageants.

A lot of people look at these threads as "how to" threads, so with that in mind, I'd like to raise a few points simply to provide an alternative viewpoint for discussion, not as a criticism of the work Brad was kind enough to share.

You'll read a lot that a rough finish does not have much of an effect on flow, which is true, but there is a big difference between a rough finish, and an uneven finish. I'm sure the camera exaggerates the effect, but if you can see the tracks of the burr, then the finish is uneven enough to produce eddies that do have a negative effect on flow. Given the overall improvement in flow from the port work itself, this might be marginal, but one side effect of the eddies is carbon buildup. You don't need a mirror finish, but the surfaces should be even for maximum flow.

You can say it doesn't matter, but the people that have flow benches seem to think it does...

Yes they're flat. It's ported no differently than many other a saw I've ported. The transfers on my 346 are probably wider.

Like the 440? I don't like the squareness of the port edges, because it can be hard on the rings (or catastrophic if a ring hangs). That doesn't mean it won't work out fine in most cases, but the risk is real.

Another consideration for port shape, however is symmetry. With one round profile and one square profile, the ring gets forced back into the cylinder unevenly. This can stress the ring, because it is not free to move, and can cause the ring to bear unevenly on the pin, to the point of working it loose with enough use.

Speaking of symmetry, the only real danger to working on the transfers is producing a lack of symmetry. If one flows better than another, the efficiency of scavenging drops off dramatically. The saw won't run noticeably poorly, (especially at high rpms) but it will be a ways from optimal. If you are going to work on the transfers, you should find a way to test whether they have symmetrical flow.

Like the 440?

Yes, exactly like the 440. BTW, these ports were ground from the outside with a round burr, all be it a small diameter one.

Yes, exactly like the 440. BTW, these ports were ground from the outside with a round burr, all be it a small diameter one.

I saw that...I always wanted to be inside a transfer port! Very convenient!

I try to stay away from the square burrs too. Makes a mess of things.

Port timing on this saw was as follows.

Exhaust 104°

Transfers 125°

Intake 70°

I left the exhaust and transfers alone. I didn't want to lower the intake floor that much. That would likely take it down into the impulse area. So I trimmed the intake piston skirt to get it to 80°

Exhaust 104°

Transfers 125°

Intake 70°

I left the exhaust and transfers alone. I didn't want to lower the intake floor that much. That would likely take it down into the impulse area. So I trimmed the intake piston skirt to get it to 80°

Mastermind

Work Saw Specialist

It's just a cheapie from HF. The solvent actually cost more than the washer itself.

Is your washer one of the cheap ones that are just suppose to use non-flammables?