Hello all,

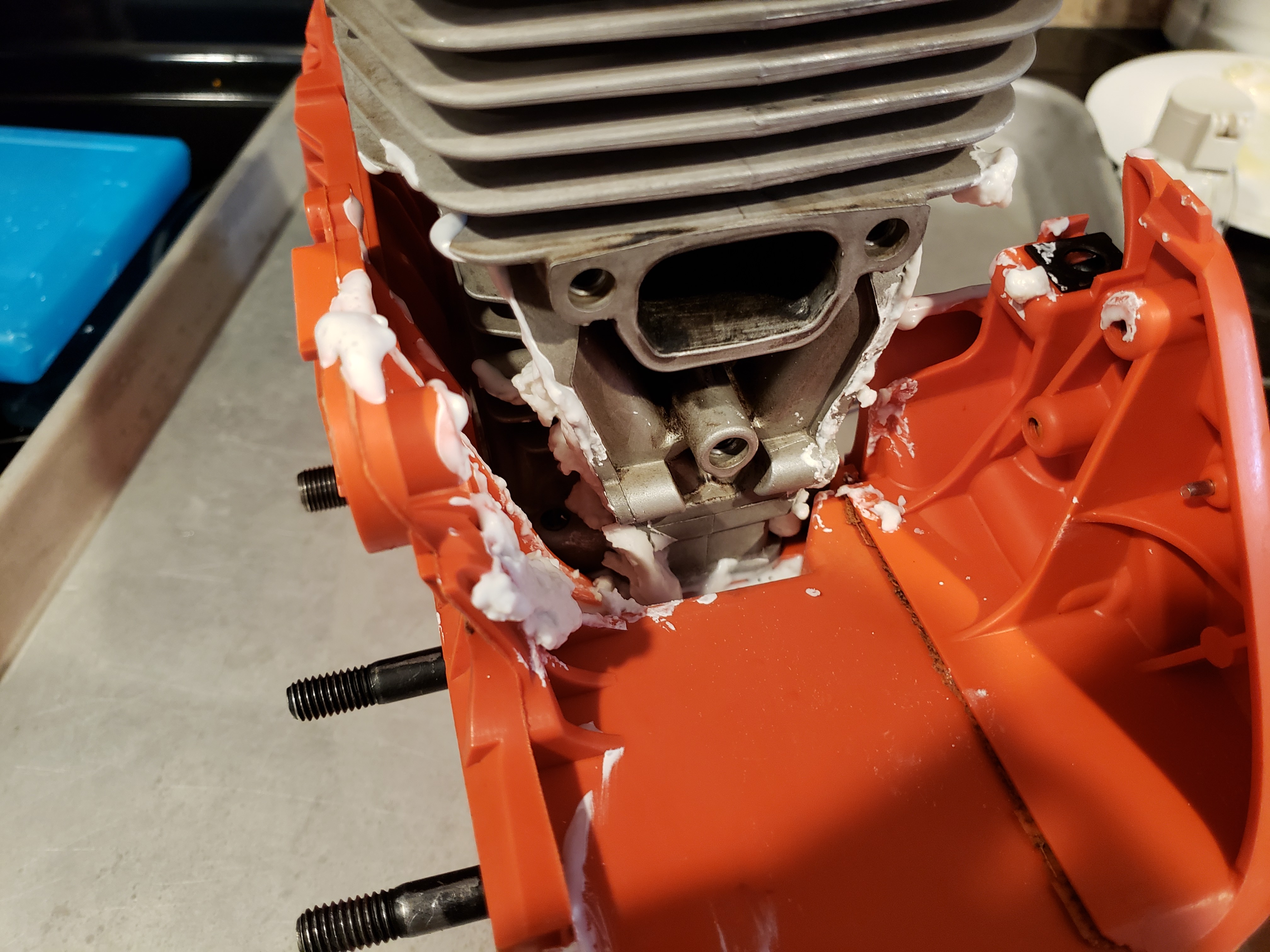

New to the forum, just got a saw in trade and I plan on cleaning it up and seeing what I can get out of it. The saw is a 2012 455 rancher(I know not the best but its what I got). 24" bar, chisel chain, full skip. I will probably keep a 24" bar on it long term.

I am starting off with all new lines, the gas tank line already fell apart. My plan is to grab a 49mm cylinder and piston assembly from Baileys model HVP 537 32 05 01. Tell me if that is the wrong one

Once I have that I will probably test port the current piston, as another member suggested(@Terry Syd). Once I have that down I will do the 49mm set up.

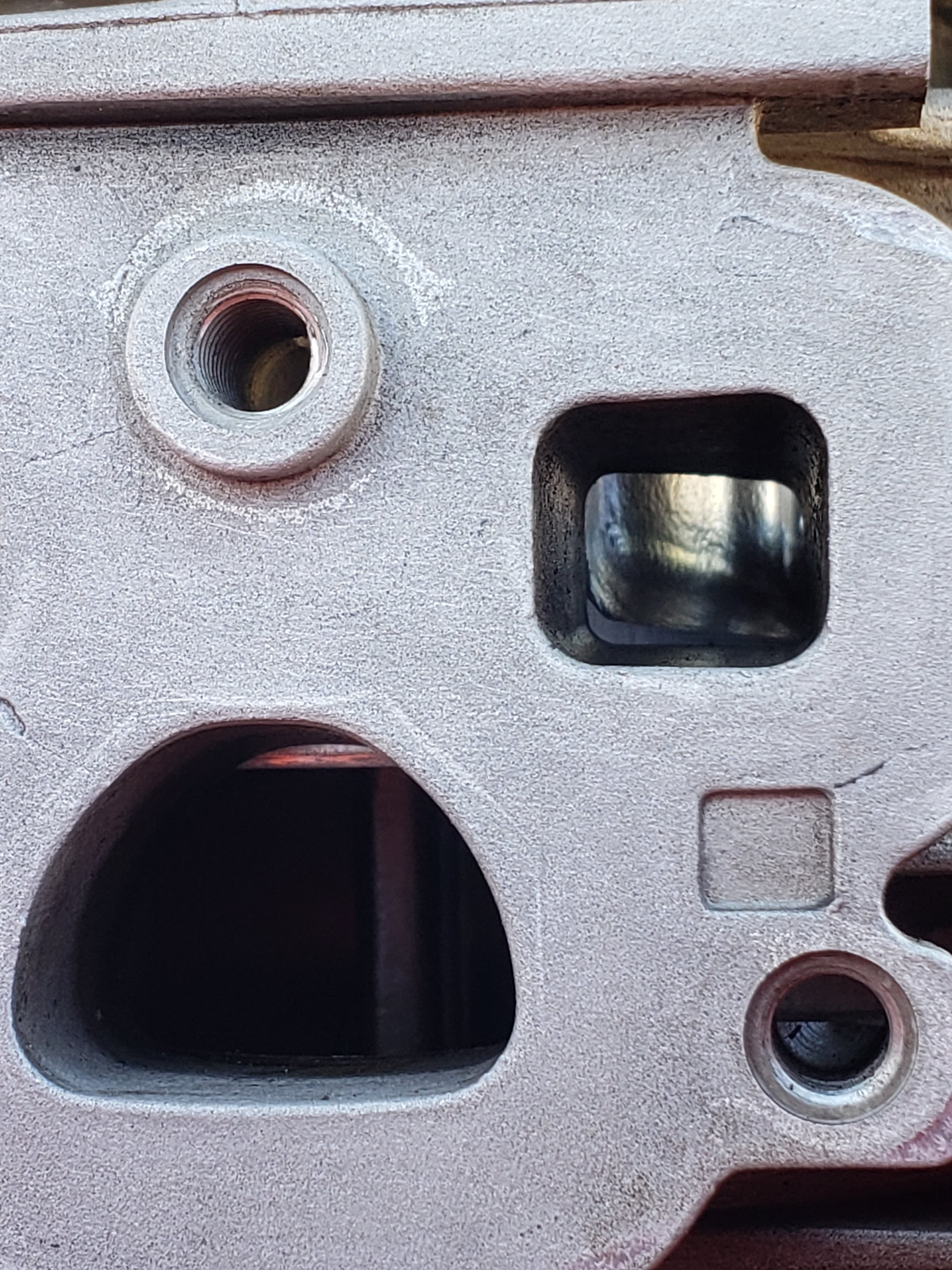

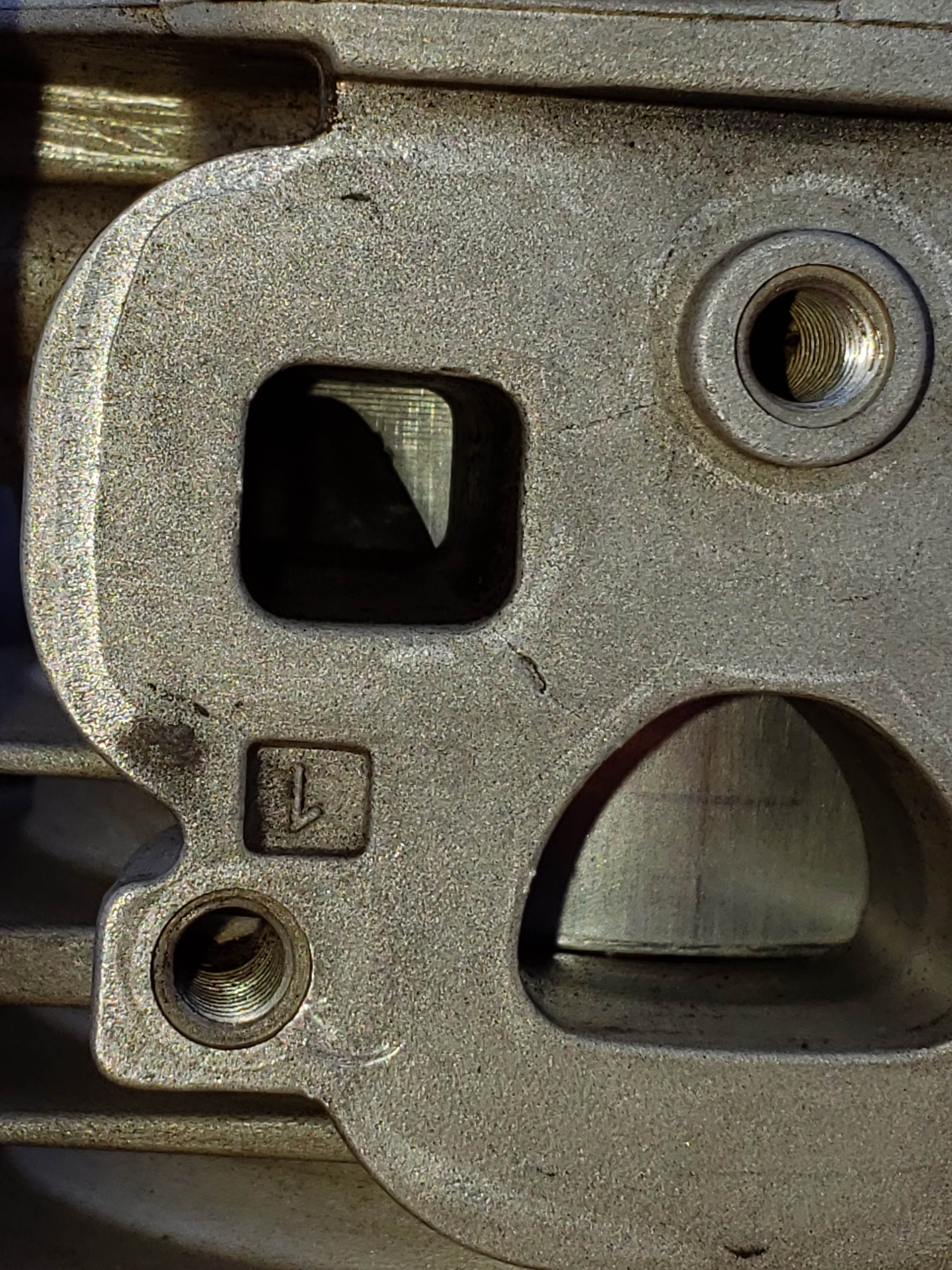

Does this sound right? Thanks for your input, I will throw pics up as I go. I dont see very many detail images so hopefully I can share some good stuff.

New to the forum, just got a saw in trade and I plan on cleaning it up and seeing what I can get out of it. The saw is a 2012 455 rancher(I know not the best but its what I got). 24" bar, chisel chain, full skip. I will probably keep a 24" bar on it long term.

I am starting off with all new lines, the gas tank line already fell apart. My plan is to grab a 49mm cylinder and piston assembly from Baileys model HVP 537 32 05 01. Tell me if that is the wrong one

Once I have that I will probably test port the current piston, as another member suggested(@Terry Syd). Once I have that down I will do the 49mm set up.

Does this sound right? Thanks for your input, I will throw pics up as I go. I dont see very many detail images so hopefully I can share some good stuff.