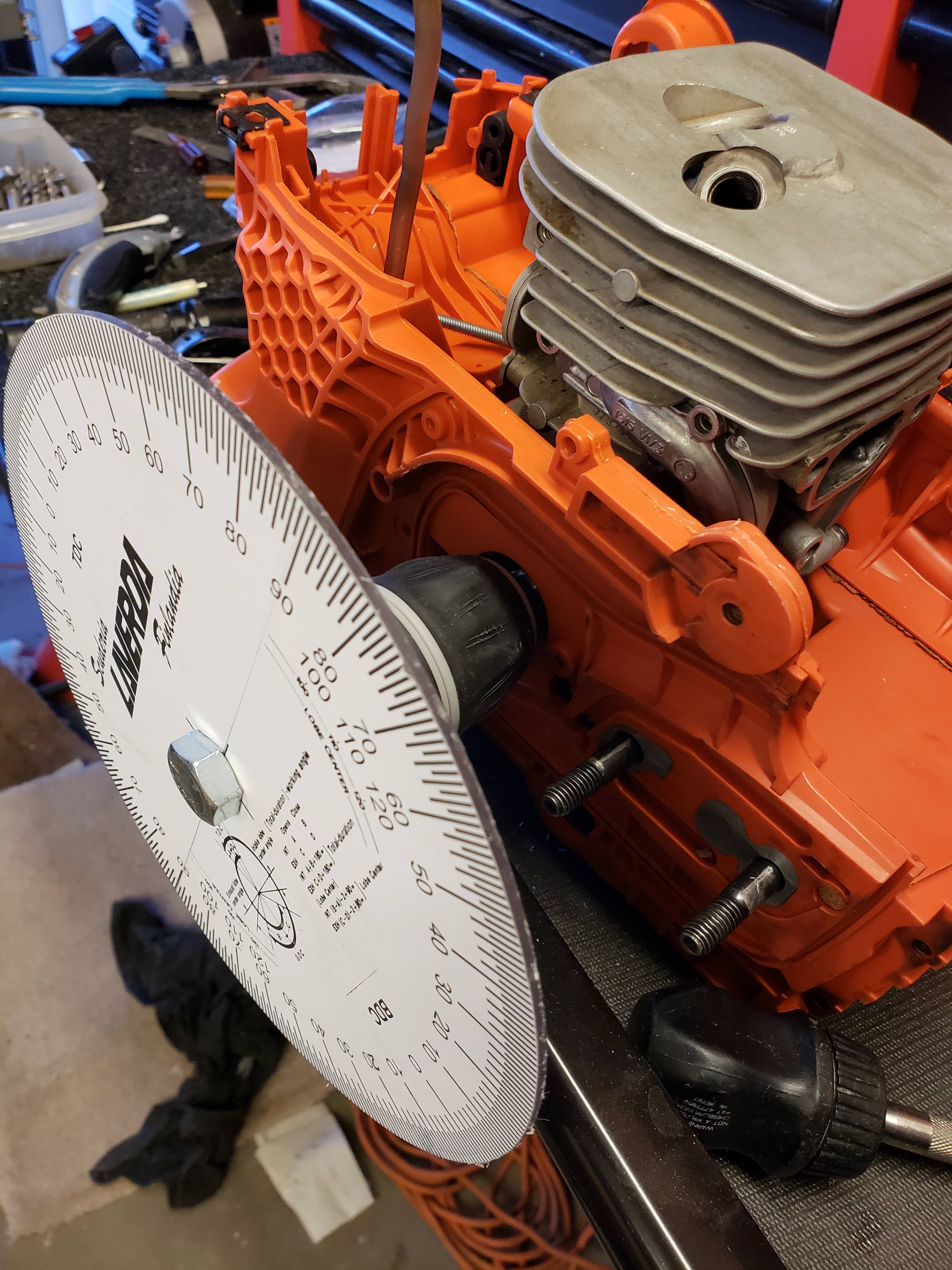

View attachment 647073

Just a little of what I did....

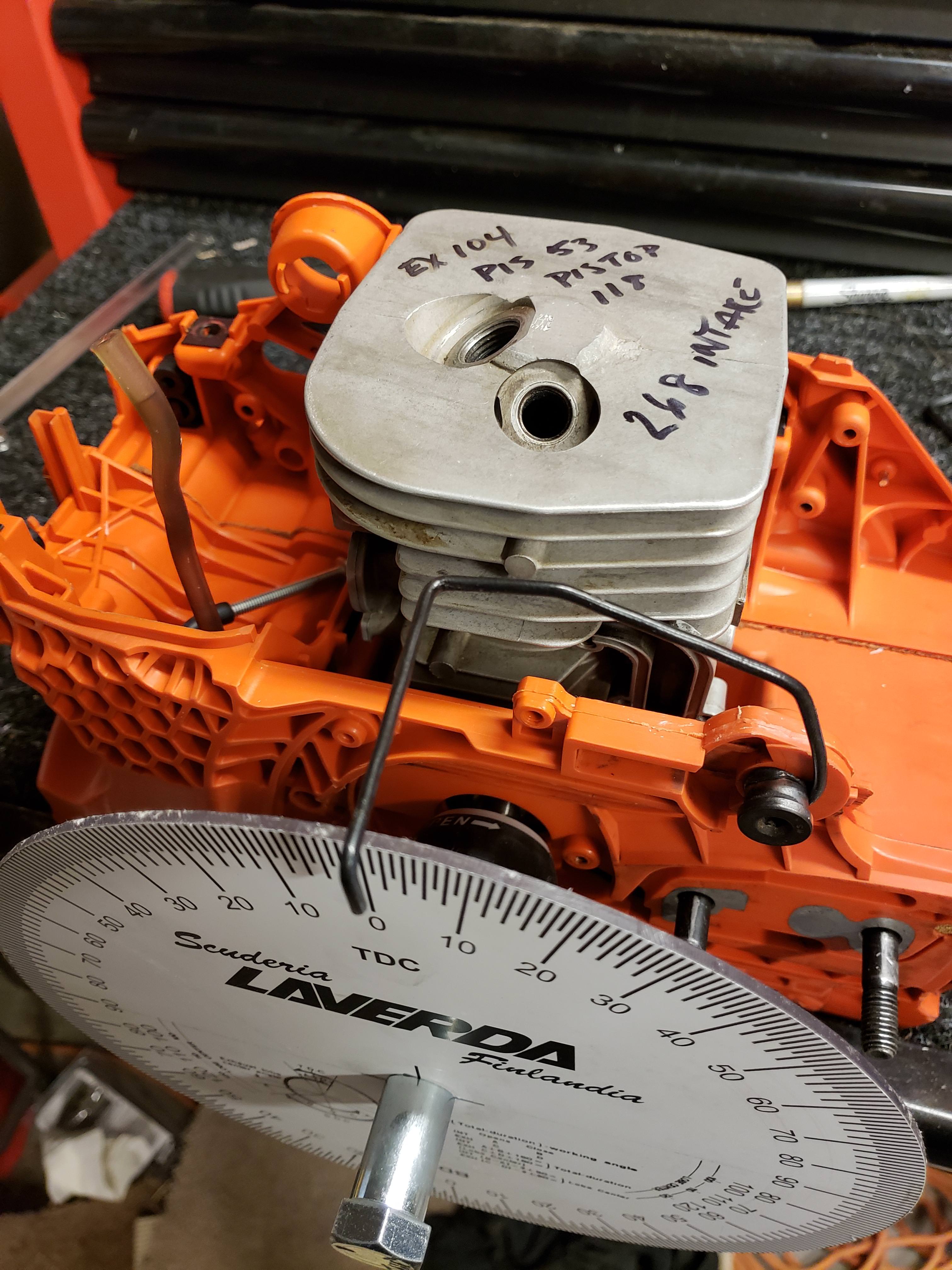

In the stratosphere port you can see the onerlap of the piston....I market that and removed that from the piston and just did clean up to the port itself,

The intake port I brought the top corners up to add volume of intake. I didn’t go drastic as I believe the ring end gap is in the center of the port. It was very noticeable what was done when finished. Make sure to really bevel and smooth the edges of the port.

I also took 20 thousands off the bottom of the piston where it opens on the intake.

So my question...even though the intake boot from the carb is that shape it's still beneficial to open it like that behind the boot?