thomas1

sodium pentothal

- Joined

- May 2, 2010

- Messages

- 3,651

- Reaction score

- 1,092

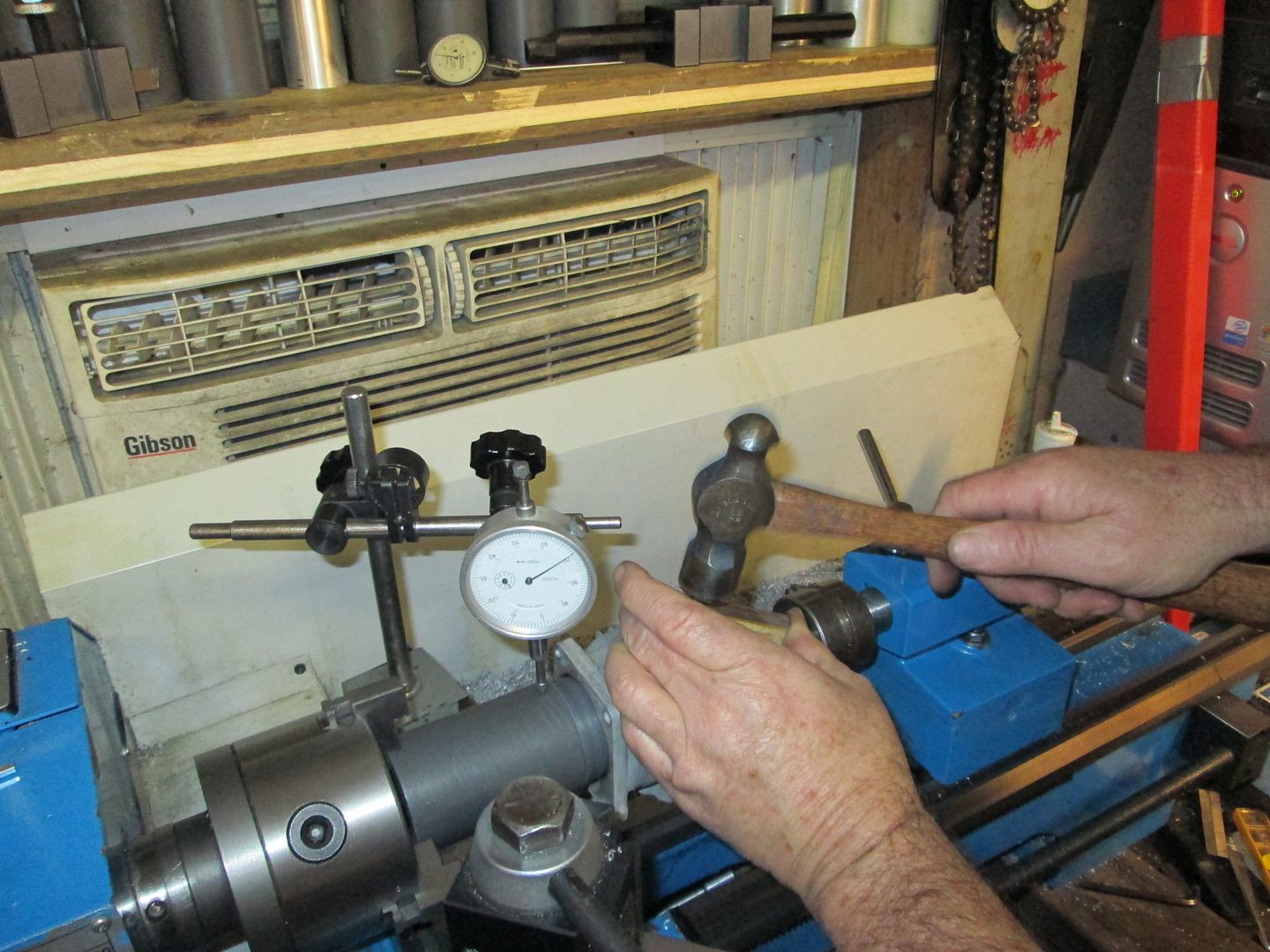

K. Thx. Bye.I use the adjustable jointed piece a lot Thomas. It's real handy.

K. Thx. Bye.I use the adjustable jointed piece a lot Thomas. It's real handy.

This is definitely the best saw building thread I've seen. I too wish I could see a video on every stage of the build. Anyway the lathe work and the porting work. Thanks a lot Randy. I thought I heard Stevie Ray Vaughan on one of those videos. You're a man of fine taste also.

I saw SRV in Raleigh, NC many years ago.........changed muh life.

I saw SRV in Raleigh, NC many years ago.........changed muh life.

it was really the sheep and thomas1I thought Jenny Craig changed your life?

I thought Jenny Craig changed your life?

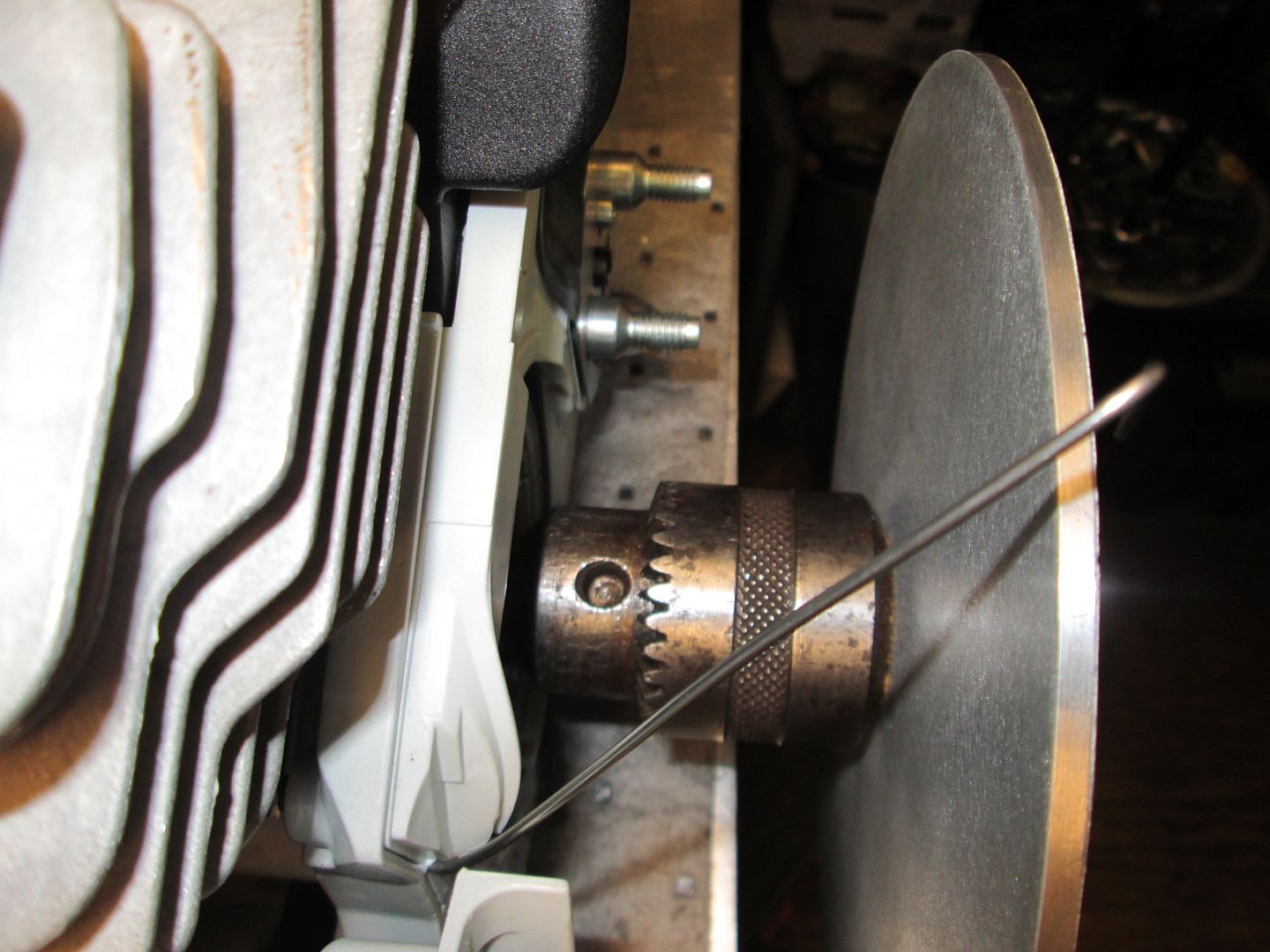

Great tutorial Randy. Is this the lathe that you picked up at Ernie's?

Enter your email address to join: