Gregg, that looks pro fessinal if'n I do say so myself.......

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nik's Poulan Thread

- Thread starter FATGUY

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

The Dayton 4Z252 that 04titanse picked up for me last week arrived today. The saw looks to be in solid condition, it is one owner and came with the wrench and a bunch of literature in the original envelope from W.W. Grainger.

While the saw was clean (the bar plates are like new), I gave it a good cleaning. When I pulled the muffler this is what I saw:

Got it back together and it has 160# of compression. Just proves it pays to take the time to look a saw over before cranking it. Now to find a bar for it...

Nice saw! You also gave a good example of why I cringe whenever I hear someone say they found a saw thats been stitting for 100 years and the first thing they do is to gas er up and tried to start it. :msp_rolleyes:

I learned that with my WildThing. Did exactly what you said. Keep opening the Lo needle whlie squeezing the throttle. Was surprised as it must be 2 turns open or more.

Bob

Well i got the 42 cc strato Craftsman running. New carb,piston assembly lines and ignition module, so I am 65 $ and too many hours into a $75 saw. But learned while doing it. 2.75 turns out low and 1.75 high, made me glad I listened to you guys. I am sure the too big muff mod I did, is not helping. Would have never thought......but is is running/cutting well.

stratos muff mod

I'm just putting one back together ( lean scoring by someone else). The mufflers on these are quite different than the older 42cc poulans, so any advice, photos of what you did would be welcomed.

Be safe,

Lee

Well i got the 42 cc strato Craftsman running. New carb,piston assembly lines and ignition module, so I am 65 $ and too many hours into a $75 saw. But learned while doing it. 2.75 turns out low and 1.75 high, made me glad I listened to you guys. I am sure the too big muff mod I did, is not helping. Would have never thought......but is is running/cutting well.

I'm just putting one back together ( lean scoring by someone else). The mufflers on these are quite different than the older 42cc poulans, so any advice, photos of what you did would be welcomed.

Be safe,

Lee

I'm just putting one back together ( lean scoring by someone else). The mufflers on these are quite different than the older 42cc poulans, so any advice, photos of what you did would be welcomed.

Be safe,

Lee

These must be set pretty lean, and/or my buddy did not use alot of sense. This had some scoring, and the piston and cylinder had a baked on powder coat and the ring was froze. The ignition was done and flywheel grooved from riding on the contacts, as the coil anchor threads were stripped. The cracked intake was the cherry on top. I got a new ignition, intake, buffed the flywheel on a lathe, and JB weld and tapped the mounting holes.

Anyway...I removed the deflector and open the exhast slit along the bottom and curled it around to the open end of the deflector. I did not feel like opening the can to get to the diffuser, so I bent it down(needlenose pliers) to funnel exhaust straight to the deflector. Then I pryed up the deflector opening and put it back on. Even before the mod this thing needed two turns out on the low to idle. It needs close to three to accelerate on throttle. Compression is great with new ring and piston, so I am surprised I am almost double the recommended low setting of 1.5 turns. The boys here counseled me to keep going on the low adjustment.....:dunno:

Hopefully, will be a good little saw now. Good luck,

Chris

Last edited:

Flintknapper

ArboristSite Operative

Questions...?

Looks like I am going to be doing some ‘noodling’ today (not because I want to).

The firewood I cut recently is just too big for me to handle (load on trailer) and I don’t want to split it where it is….so I am going to cut the pieces in half…then load on the trailer.

I could take the tractor down there….but I think it would be more work than just cutting the wood into more manageable pieces.

I haven’t (purposely) cut wood “with the grain” very much….so anything I need to watch for?

I know it is going to tend to load the saw (as the chips/noodles will be longer)….so I am guessing I need to just let the saw do the work at its own pace?

Probably use my 4900 for this. Any need to adjust the oiler to a higher rate?

Any tips will be appreciated.

Thanks,

Flint.

Looks like I am going to be doing some ‘noodling’ today (not because I want to).

The firewood I cut recently is just too big for me to handle (load on trailer) and I don’t want to split it where it is….so I am going to cut the pieces in half…then load on the trailer.

I could take the tractor down there….but I think it would be more work than just cutting the wood into more manageable pieces.

I haven’t (purposely) cut wood “with the grain” very much….so anything I need to watch for?

I know it is going to tend to load the saw (as the chips/noodles will be longer)….so I am guessing I need to just let the saw do the work at its own pace?

Probably use my 4900 for this. Any need to adjust the oiler to a higher rate?

Any tips will be appreciated.

Thanks,

Flint.

zogger

Tree Freak

Looks like I am going to be doing some ‘noodling’ today (not because I want to).

The firewood I cut recently is just too big for me to handle (load on trailer) and I don’t want to split it where it is….so I am going to cut the pieces in half…then load on the trailer.

I could take the tractor down there….but I think it would be more work than just cutting the wood into more manageable pieces.

I haven’t (purposely) cut wood “with the grain” very much….so anything I need to watch for?

I know it is going to tend to load the saw (as the chips/noodles will be longer)….so I am guessing I need to just let the saw do the work at its own pace?

Probably use my 4900 for this. Any need to adjust the oiler to a higher rate?

Any tips will be appreciated.

Thanks,

Flint.

Yes, just let it feed, use a wedge to keep the kerf open, cut at a slight angle. Lift the saw to let the noddles clear as needed.

Noodle cuts are actually easier than bucking cuts or ripping cuts. You just get long noodles, thats all.

rms61moparman

Addicted to ArboristSite

The noodles will get shorter if you let the tip of the bar go considerably deeper than the heel.

It will help keep the clutch cover from getting so clogged up.

Personally, if I were doing that with the saws you have, I would take the bar cover off and replace it with a couple stacks of flat washers.

But I would NEVER suggest someone else doing that!

Mike

It will help keep the clutch cover from getting so clogged up.

Personally, if I were doing that with the saws you have, I would take the bar cover off and replace it with a couple stacks of flat washers.

But I would NEVER suggest someone else doing that!

Mike

The noodles will get shorter if you let the tip of the bar go considerably deeper than the heel.

It will help keep the clutch cover from getting so clogged up.

Personally, if I were doing that with the saws you have, I would take the bar cover off and replace it with a couple stacks of flat washers.

But I would NEVER suggest someone else doing that!

Mike

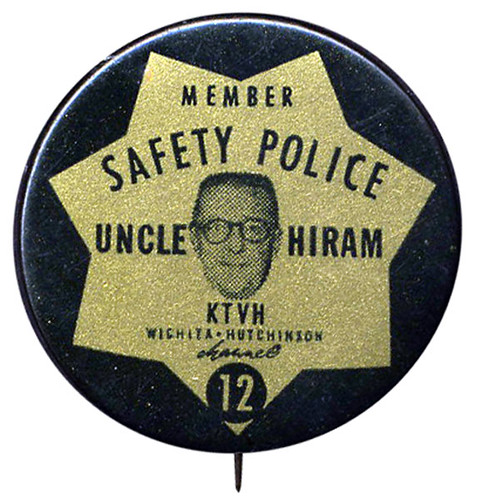

I like that advice. I was thinking the same thing, but didn't have the guts to say it. (safety police could be lurking). I have never tried it, but I might.:msp_wink: I don't noodle cut very often. When I do, I just use my 385xp, it clears them much better. Can still plug, but not as bad as the Poulans.

I like that advice. I was thinking the same thing, but didn't have the guts to say it. (safety police could be lurking). I have never tried it, but I might.:msp_wink: I don't noodle cut very often. When I do, I just use my 385xp, it clears them much better. Can still plug, but not as bad as the Poulans.Gregg,

Guido Salvage

Supreme Saw Whoreder

Someone call the safety police?

I would take the bar cover off and replace it with a couple stacks of flat washers.

But I would NEVER suggest someone else doing that!

Mike

I had a small mount 362xp I built from scratch and hadnt found a clutch cover for once I had got to the firing up stage. Big mistake test cutting without clutch cover.

I then modded a large mount 372 cover to fit the small mount 362 till I found a oem small mount cover. :biggrin:

HeRoze

Addicted to ArboristSite

I had a small mount 362xp I built from scratch and hadnt found a clutch cover for once I had got to the firing up stage. Big mistake test cutting without clutch cover.

... do tell.

... do tell.

Nothing to tell. You will wear and eat a whole lot of chips. :msp_wink:

:hmm3grin2orange:

:hmm3grin2orange:rms61moparman

Addicted to ArboristSite

Nothing to tell. You will wear and eat a whole lot of chips. :msp_wink::hmm3grin2orange:

The pine flavored ones aren't too bad.

The walnut SUX!!!

Mike

redunshee

Addicted to ArboristSite

I like that advice. I was thinking the same thing, but didn't have the guts to say it. (safety police could be lurking). I have never tried it, but I might.:msp_wink: I don't noodle cut very often. When I do, I just use my 385xp, it clears them much better. Can still plug, but not as bad as the Poulans.

Gregg,

With the bar and chain on will it remove the possibility of the clutch coming off?

Flintknapper

ArboristSite Operative

Done.........

Well that wasn't so bad. I am always impressed at how ‘torque-y’ this saw (and the S25) is.

It just never gives up.

Holding the saw parallel with the ground…made for smooth cutting (and no effort on my part), but produced a LOT of long noodles quickly.

Working the tip down into the wood and then following with the heel (as per normal bucking) was considerably faster and didn’t clog the clutch cover. The noodles were much shorter that way (almost chips) and I still got a smooth cut.

Done in about 30 minutes. Took the time to tune my saw (in the wood) after the first cut.

Even cut one smaller piece with my S25. Had a new (sharp) low profile chain on it….and it really did a good job.

My 3400 and 3800 suck….compared to the S25 and the 4900, both saws make amazing power for their size.

Anyway, I am now ‘initiated’.

Thanks for the tips guys.

Flint.

Well that wasn't so bad. I am always impressed at how ‘torque-y’ this saw (and the S25) is.

It just never gives up.

Holding the saw parallel with the ground…made for smooth cutting (and no effort on my part), but produced a LOT of long noodles quickly.

Working the tip down into the wood and then following with the heel (as per normal bucking) was considerably faster and didn’t clog the clutch cover. The noodles were much shorter that way (almost chips) and I still got a smooth cut.

Done in about 30 minutes. Took the time to tune my saw (in the wood) after the first cut.

Even cut one smaller piece with my S25. Had a new (sharp) low profile chain on it….and it really did a good job.

My 3400 and 3800 suck….compared to the S25 and the 4900, both saws make amazing power for their size.

Anyway, I am now ‘initiated’.

Thanks for the tips guys.

Flint.

Wood ID

I'm not sure where to post this but I was wondering if anyone could ID this wood.

I picked up a bit of for my fireplace wood stock. It did not split easily and I don't think there was a straight grained piece in the lot.

It has threads of bright pink, almost red color running through it. High water content. The trunk was quartered but was probably

28" in diameter. I had to noodle most of it with the 4200

I'm not sure where to post this but I was wondering if anyone could ID this wood.

I picked up a bit of for my fireplace wood stock. It did not split easily and I don't think there was a straight grained piece in the lot.

It has threads of bright pink, almost red color running through it. High water content. The trunk was quartered but was probably

28" in diameter. I had to noodle most of it with the 4200

Dry it, bag it and peddle it to the pet store for hamster bedding.

cowroy

Addicted to ArboristSite

I was wondering if anyone could ID this wood.

Boxelder :msp_wink:

Boxelder :msp_wink:

I was hoping not the hear that but, backyard fires I guess.

Thanks

Similar threads

- Replies

- 3

- Views

- 898