The 'Z' is the give away.there is also a Z on some of the non cutter, non drive links.

Of course, I can't recall which brand it is, but I know that we have discussed this before, here on A.S.! Maybe @SawTroll can remind us?

Philbert

The 'Z' is the give away.there is also a Z on some of the non cutter, non drive links.

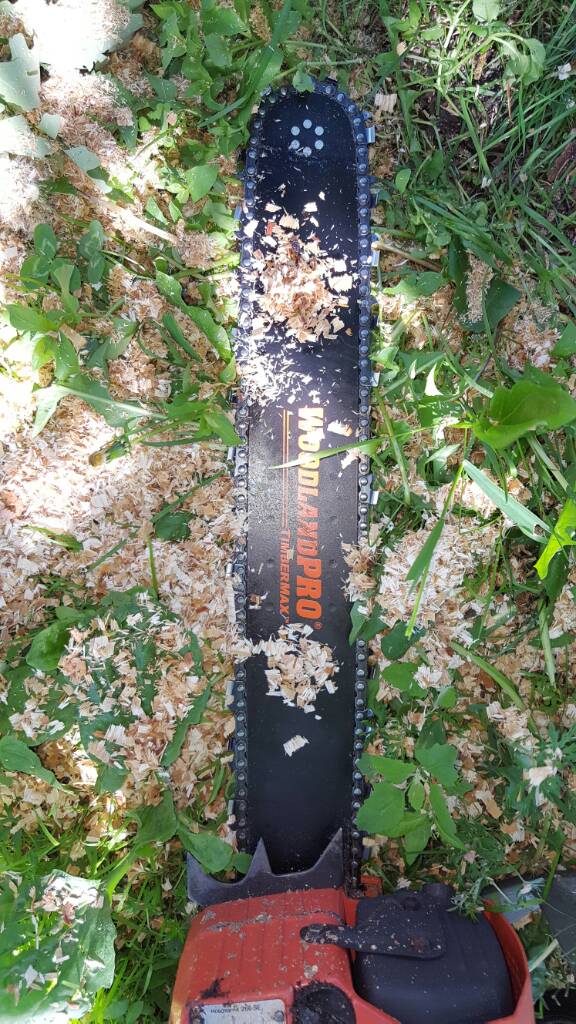

Sorry Brian,Here are a couple pics. I sharpened it per the Oregon 72DG instructions, at least all the angles and cutter lengths are the same now. 3/16 wheel, 60/30/0 so I will see how it cuts.

there is also a Z on some of the non cutter, non drive links.

Brian

Good to start with good, clean metal.I judge how much to take by looking face on at the cutter and keep adjusting the stop until I get a full ground face.

That's not something that I often get accused of!. . . this time you are clearly far to diplomatic!

......

OR:

Shape the cutter as best as you can with the 3/16" wheel and finish it off with a file to get the final profile and edge.

Philbert

Mail those chips to 7sleeper - he can make a nice salad out of them!I think pictures can be deceiving. . . nice long chips from the old chain.

Take it back to a 'normal' 35 degree or go with the average?

This is on a gear drive Remy BTW.

cutting good enough for me! I am just leaving that chain on.Mail those chips to 7sleeper - he can make a nice salad out of them!

Philbert

Enter your email address to join: