WesternSaw

Addicted to ArboristSite

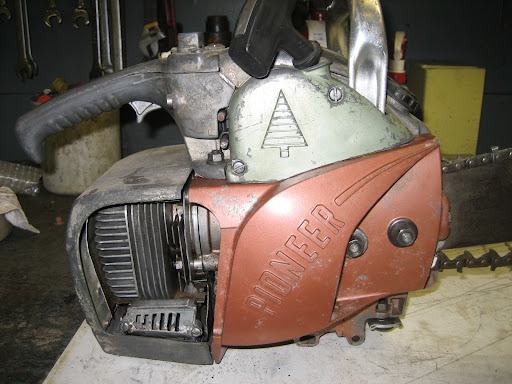

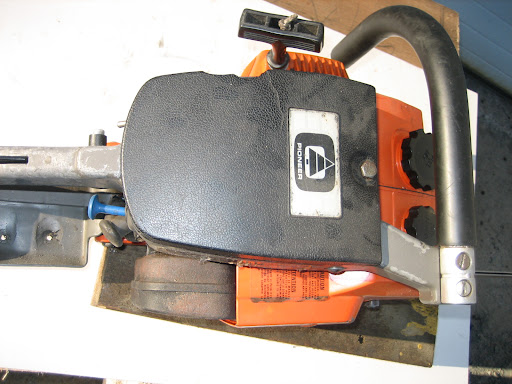

Cleaning up a P20

Hi guys

My neighbour knows that I'm starting to get into this Pioneer thing of late so he was on a trip upcounry last weekend and in the metal scrap pile at the local dump is a P20 sitting there,it is in not great shape but some part's may be of use.I started to get the grime and dust off and thought I would take a lookbehind the flywheel.How do I hold the flywheel from turning while trying to get the flywheel nut off?I looked in my Pioneer manuals and all it mentions is the left hand threading.I know I need a puller once the nut is off .Please remember I am just starting with the saw mechanic thing.

Thanks Lawrence

P.S.l allready broke a flywheel fin off.Yikes!

Hi guys

My neighbour knows that I'm starting to get into this Pioneer thing of late so he was on a trip upcounry last weekend and in the metal scrap pile at the local dump is a P20 sitting there,it is in not great shape but some part's may be of use.I started to get the grime and dust off and thought I would take a lookbehind the flywheel.How do I hold the flywheel from turning while trying to get the flywheel nut off?I looked in my Pioneer manuals and all it mentions is the left hand threading.I know I need a puller once the nut is off .Please remember I am just starting with the saw mechanic thing.

Thanks Lawrence

P.S.l allready broke a flywheel fin off.Yikes!